Page 11: of Maritime Reporter Magazine (May 15, 1977)

Read this page in Pdf, Flash or Html5 edition of May 15, 1977 Maritime Reporter Magazine

Norfolk Shipbuilding And Drydock Corporation

Signs Two Multimillion-Dollar Contracts

IHI Delivers 269,800-DWT Texaco Caribbean

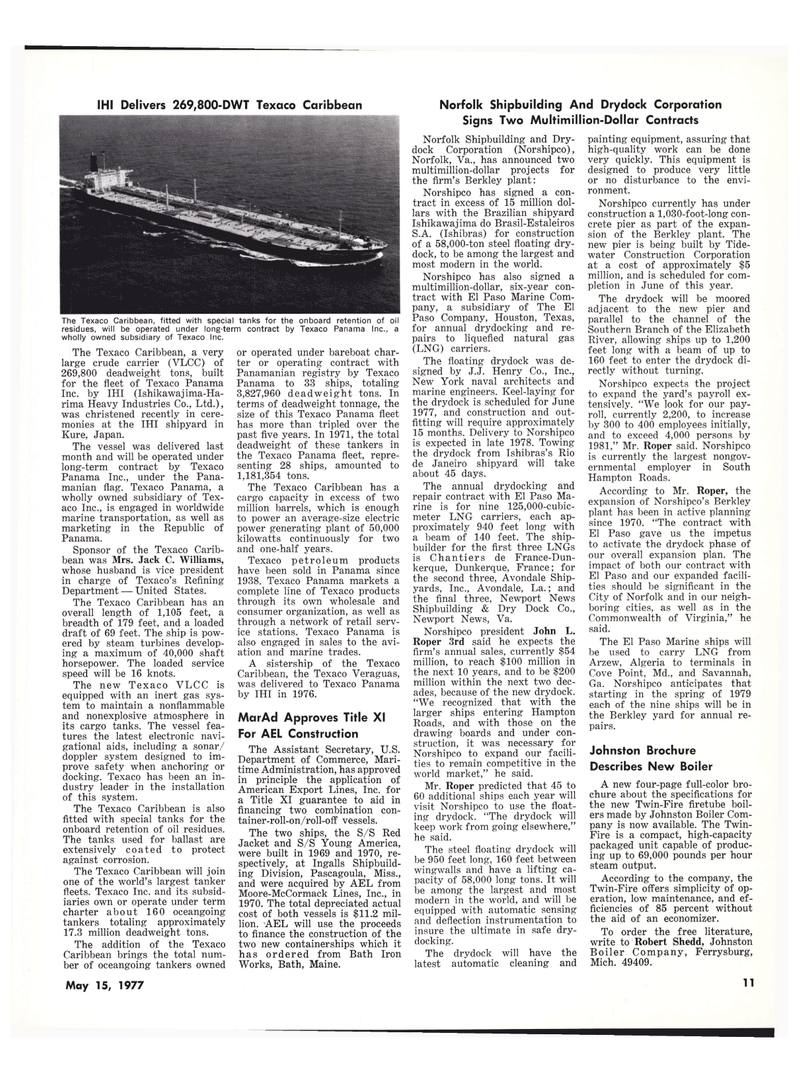

The Texaco Caribbean, fitted with special tanks for the onboard retention of oil residues, will be operated under long-term contract by Texaco Panama Inc., a wholly owned subsidiary of Texaco Inc.

The Texaco Caribbean, a very large crude carrier (VLCC) of 269,800 deadweight tons, built for the fleet of Texaco Panama

Inc. by IHI (Ishikawajima-Ha- rima Heavy Industries Co., Ltd.), was christened recently in cere- monies at the IHI shipyard in

Kure, Japan.

The vessel was delivered last month and will be operated under long-term contract by Texaco

Panama Inc., under the Pana- manian flag. Texaco Panama, a wholly owned subsidiary of Tex- aco Inc., is engaged in worldwide marine transportation, as well as marketing in the Republic of

Panama.

Sponsor of the Texaco Carib- bean was Mrs. Jack C. Williams, whose husband is vice president in charge of Texaco's Refining

Department — United States.

The Texaco Caribbean has an overall length of 1,105 feet, a breadth of 179 feet, and a loaded draft of 69 feet. The ship is pow- ered by steam turbines develop- ing a maximum of 40,000 shaft horsepower. The loaded service speed will be 16 knots.

The new Texaco VLCC is equipped with an inert gas sys- tem to maintain a nonflammable and nonexplosive atmosphere in its cargo tanks. The vessel fea- tures the latest electronic navi- gational aids, including a sonar/ doppler system designed to im- prove safety when anchoring or docking. Texaco has been an in- dustry leader in the installation of this system.

The Texaco Caribbean is also fitted with special tanks for the onboard retention of oil residues.

The tanks used for ballast are extensively coated to protect against corrosion.

The Texaco Caribbean will join one of the world's largest tanker fleets. Texaco Inc. and its subsid- iaries own or operate under term charter about 160 oceangoing tankers totaling approximately 17.3 million deadweight tons.

The addition of the Texaco

Caribbean brings the total num- ber of oceangoing tankers owned or operated under bareboat char- ter or operating contract with

Panamanian registry by Texaco

Panama to 33 ships, totaling 3,827,960 deadweight tons. In terms of deadweight tonnage, the size of this Texaco Panama fleet has more than tripled over the past five years. In 1971, the total deadweight of these tankers in the Texaco Panama fleet, repre- senting 28 ships, amounted to 1,181,354 tons.

The Texaco Caribbean has a cargo capacity in excess of two million barrels, which is enough to power an average-size electric power generating plant of 50,000 kilowatts continuously for two and one-half years.

Texaco petroleum products have been sold in Panama since 1938. Texaco Panama markets a complete line of Texaco products through its own wholesale and consumer organization, as well as through a network of retail serv- ice stations. Texaco Panama is also engaged in sales to the avi- ation and marine trades.

A sistership of the Texaco

Caribbean, the Texaco Veraguas, was delivered to Texaco Panama by IHI in 1976.

MarAd Approves Title XI

For AEL Construction

The Assistant Secretary, U.S.

Department of Commerce, Mari- time Administration, has approved in principle the application of

American Export Lines, Inc. for a Title XI guarantee to aid in financing two combination con- tainer-roll-on/roll-off vessels.

The two ships, the S/S Red

Jacket and S/S Young America, were built in 1969 and 1970, re- spectively, at Ingalls Shipbuild- ing Division, Pascagoula, Miss., and were acquired by AEL from

Moore-McCormack Lines, Inc., in 1970. The total depreciated actual cost of both vessels is $11.2 mil- lion. AEL will use the proceeds to finance the construction of the two new containerships which it has ordered from Bath Iron

Works, Bath, Maine.

Norfolk Shipbuilding and Dry- dock Corporation (Norshipco),

Norfolk, Va., has announced two multimillion-dollar projects for the firm's Berkley plant:

Norshipco has signed a con- tract in excess of 15 million dol- lars with the Brazilian shipyard

Ishikawajima do Brasil-Estaleiros

S.A. (Ishibras) for construction of a 58,000-ton steel floating dry- dock, to be among the largest and most modern in the world.

Norshipco has also signed a multimillion-dollar, six-year con- tract with El Paso Marine Com- pany, a subsidiary of The El

Paso Company, Houston, Texas, for annual drydocking and re- pairs to liquefied natural gas (LNG) carriers.

The floating drydock was de- signed by J.J. Henry Co., Inc.,

New York naval architects and marine engineers. Keel-laying for the drydock is scheduled for June 1977, and construction and out- fitting will require approximately 15 months. Delivery to Norshipco is expected in late 1978. Towing the drydock from Ishibras's Rio de Janeiro shipyard will take about 45 days.

The annual drydocking and repair contract with El Paso Ma- rine is for nine 125,000-cubic- meter LNG carriers, each ap- proximately 940 feet long with a beam of 140 feet. The ship- builder for the first three LNGs is Chantiers de France-Dun- kerque, Dunkerque, France; for the second three, Avondale Ship- yards, Inc., Avondale, La.; and the final three, Newport News

Shipbuilding & Dry Dock Co.,

Newport News, Va.

Norshipco president John L.

Roper 3rd said he expects the firm's annual sales, currently $54 million, to reach $100 million in the next 10 years, and to be $200 million within the next two dec- ades, because of the new drydock. "We recognized that with the larger ships entering Hampton

Roads, and with those on the drawing boards and under con- struction, it was necessary for

Norshipco to expand our facili- ties to remain competitive in the world market," he said.

Mr. Roper predicted that 45 to 60 additional ships each year will visit Norshipco to use the float- ing drydock. "The drydock will keep work from going elsewhere," he said.

The steel floating drydock will be 950 feet long, 160 feet between wingwalls and have a lifting ca- pacity of 58,000 long tons. It will be among the largest and most modern in the world, and will be equipped with automatic sensing and deflection instrumentation to insure the ultimate in safe dry- docking.

The drydock will have the latest automatic cleaning and painting equipment, assuring that high-quality work can be done very quickly. This equipment is designed to produce very little or no disturbance to the envi- ronment.

Norshipco currently has under construction a 1,030-foot-long con- crete pier as part of the expan- sion of the Berkley plant. The new pier is being built by Tide- water Construction Corporation at a cost of approximately $5 million, and is scheduled for com- pletion in June of this year.

The drydock will be moored adjacent to the new pier and parallel to the channel of the

Southern Branch of the Elizabeth

River, allowing ships up to 1,200 feet long with a beam of up to 160 feet to enter the drydock di- rectly without turning.

Norshipco expects the project to expand the yard's payroll ex- tensively. "We look for our pay- roll, currently 2,200, to increase by 300 to 400 employees initially, and to exceed 4,000 persons by 1981," Mr. Roper said. Norshipco is currently the largest nongov- ernmental employer in South

Hampton Roads.

According to Mr. Roper, the expansion of Norshipco's Berkley plant has been in active planning since 1970. "The contract with

El Paso gave us the impetus to activate the drydock phase of our overall expansion plan. The impact of both our contract with

El Paso and our expanded facili- ties should be significant in the

City of Norfolk and in our neigh- boring cities, as well as in the

Commonwealth of Virginia," he said.

The El Paso Marine ships will be used to carry LNG from

Arzew, Algeria to terminals in

Cove Point, Md., and Savannah,

Ga. Norshipco anticipates that starting in the spring of 1979 each of the nine ships will be in the Berkley yard for annual re- pairs.

Johnston Brochure

Describes New Boiler

A new four-page full-color bro- chure about the specifications for the new Twin-Fire firetube boil- ers made by Johnston Boiler Com- pany is now available. The Twin-

Fire is a compact, high-capacity packaged unit capable of produc- ing up to 69,000 pounds per hour steam output.

According to the company, the

Twin-Fire offers simplicity of op- eration, low maintenance, and ef- ficiencies of 85 percent without the aid of an economizer.

To order the free literature, write to Robert Shedd, Johnston

Boiler Company, Ferrysburg,

Mich. 49409.

May 15, 1977 11

10

10

12

12