Page 15: of Maritime Reporter Magazine (May 15, 1980)

Read this page in Pdf, Flash or Html5 edition of May 15, 1980 Maritime Reporter Magazine

First Of 60-Barge Order

Delivered By NABRICO

The first of 60 grain barges has been delivered to the American

River Transportation Company (ARTCO) by the Nashville Bridge

Company (NABRICO). The barges are 195-foot rake hopper and 200- foot box hopper barges being con- structed at the NABRICO Ash- land City, Tenn., facility.

Previously, NABRICO con- structed five 10,500-barrel chem- ical tank barges and five 195-foot bulk flour barges for ARTCO.

Founded in 1970, ARTCO is a wholly owned subsidiary of the

Archer Daniels Midland Corpora- tion of Decatur, 111. A major car- rier on the Mississippi, Illinois,

Missouri, and Ohio Rivers, ART-

CO has a fleet of more than 500 barges carrying a variety of agri- products, including grain, flour, and vegetable oils.

NABRICO is a wholly owned subsidiary of the American Ship

Building Company, Cleveland,

Ohio. Headquartered in Nashville,

Tenn., NABRICO has been in the marine field for more than 60 years and is primarily concerned with the design, engineering, and construction of barges.

R.A. Lambert Joins

Envirovac As

Marine Sales Manager

Richard A. Lambert has joined

Envirovac, Rockford, 111., as sales manager, marine systems, as an- nounced by Frank Eubank, exec- utive vice president and general manager of the company.

It weighs less than fifty pounds, has a cleaning range of 30 feet and up to 30 tons per hour throughput. and range to clean medium sized tanks or hidden areas in large tanks. The SSK machine can be fixed-in-place at any angle, weighs 55 lbs and has a throughput capacity of 80 tons per hour and an effective cleaning range of approximately 100 feet.

The SSK advantage low cost cleaning of moderate size tanks with famous Butterworth

Systems technology. "ball of twine" spray pattern that crisscrosses and overlaps for thorough cleaning.

The SK machine weighs 55 pounds and has a throughput of 30-60 tons per hour and a range of 70 feet.

The Super K advantage: low cost cleaning of hard-to- reach areas plus

Butterworth Systems reliability.

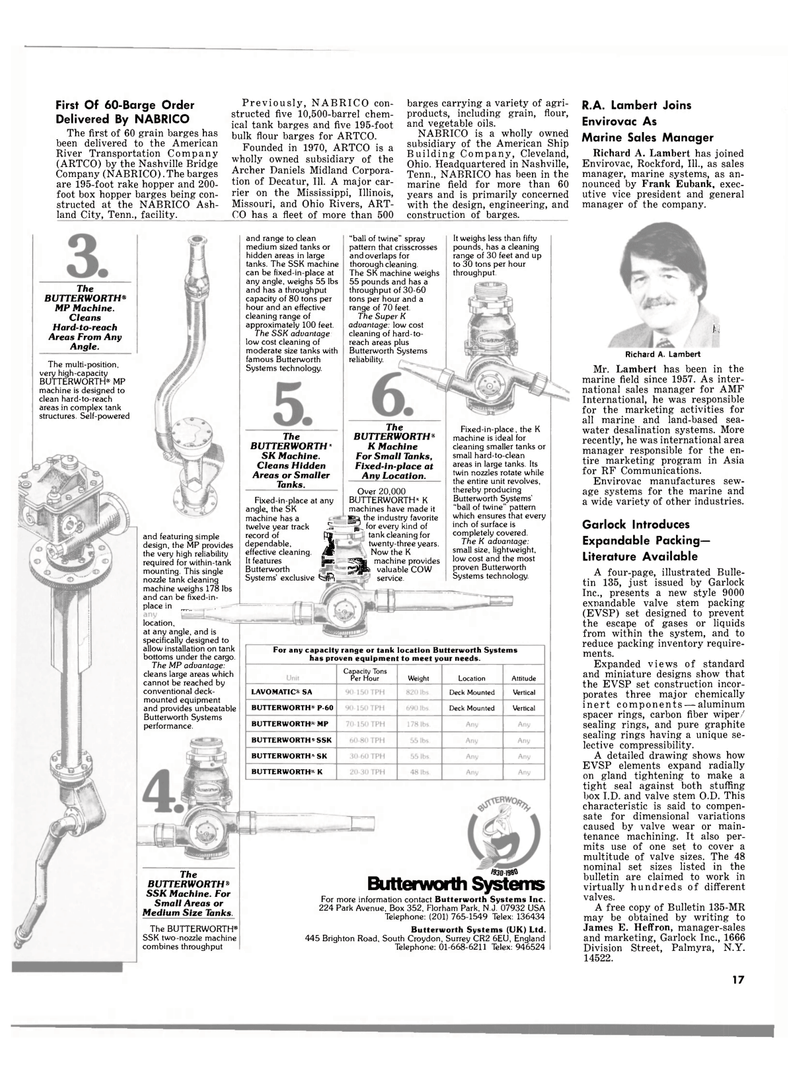

The

BUTTERWORTH®

MP Machine.

Cleans

Hard- to-reach

Areas From Any

Angle.

The multi-position, very high-capacity

BUTTERWORTH® MP machine is designed to clean hard-to-reach areas in complex tank structures. Self-powered

The

BUTTERWORTH«

K Machine

For Small Tanks,

Fixed-in-place at

Any Location.

Fixed-in-place, the K machine is ideal for cleaning smaller tanks or small hard-to-clean areas in large tanks. Its twin nozzles rotate while the entire unit revolves, thereby producing

Butterworth Systems' "ball of twine" pattern which ensures that every inch of surface is completely covered.

The K advantage: small size, lightweight, low cost and the most proven Butterworth

Systems technology.

The

BUTTERWORTH"

SK Machine.

Cleans Hidden

Areas or Smaller

Tanks.

Over 20,000

BUTTERWORTH" K machines have made it ga the industry favorite ^jgL for every kind of tank cleaning for twenty-three years.

Now the K 233b machine provides gSgfc valuable COW service.

Fixed-in-place at any angle, the SK machine has a twelve year track 5r record of pjr dependable, .ji. effective cleaning. Jff

It features |w

Butterworth

Systems' exclusive fgpi and featuring simple design, the MP provides the very high reliability required for within-tank mounting. This single nozzle tank cleaning machine weighs 178 lbs and can be fixed-in- place in _• location, at any angle, and is specifically designed to allow installation on tank bottoms under the cargo.

The MP advantage: cleans large areas which cannot be reached by conventional deck- mounted equipment and provides unbeatable

Butterworth Systems performance.

For any capacity range or tank location Butterworth Systems has proven equipment to meet your needs.

Capacity Tons

Per Hour Weight Location Attitude

LAVOMATIC* SA Deck Mounted Vertical

BUTTERWORTH » P-60 Deck Mounted Vertical

BUTTERWORTH™ MP

BUTTERWORTH® SSK

BUTTERWORTH* SK

BUTTERWORTH » K 1930-198® Butterworth Systems

For more information contact Butterworth Systems Inc. 224 Park Avenue, Box 352, Florham Park, N.J. 07932 USA

Telephone: (201) 765-1549 Telex: 136434

Butterworth Systems (UK) Ltd. 445 Brighton Road, South Croydon, Surrey CR2 6EU, England

Telephone: 01-668-6211 Telex: 946524

The

BUTTERWORTH®

SSK Machine. For

Small Areas or

Medium Size Tanks.

The BUTTERWORTH®

SSK two-nozzle machine combines throughput 1

Richard A. Lambert

Mr. Lambert has been in the marine field since 1957. As inter- national sales manager for AMF

International, he was responsible for the marketing activities for all marine and land-based sea- water desalination systems. More recently, he was international area manager responsible for the en- tire marketing program in Asia for RF Communications.

Envirovac manufactures sew- age systems for the marine and a wide variety of other industries.

Garlock Introduces

Expandable Packing-

Literature Available

A four-page, illustrated Bulle- tin 135, just issued by Garlock

Inc., presents a new style 9000 expandable valve stem packing (EVSP) set designed to prevent the escape of gases or liquids from within the system, and to reduce packing inventory require- ments.

Expanded views of standard and miniature designs show that the EVSP set construction incor- porates three major chemically inert components—-aluminum spacer rings, carbon fiber wiper ' sealing rings, and pure graphite sealing rings having a unique se- lective compressibility.

A detailed drawing shows how

EVSP elements expand radially on gland tightening to make a tight seal against both stuffing box I.D. and valve stem O.D. This characteristic is said to compen- sate for dimensional variations caused by valve wear or main- tenance machining. It also per- mits use of one set to cover a multitude of valve sizes. The 48 nominal set sizes listed in the bulletin are claimed to work in virtually hundreds of different valves.

A free copy of Bulletin 135-MR may be obtained by writing to

James E. Heffron, manager-sales and marketing, Garlock Inc., 1666

Division Street, Palmyra, N.Y. 14522. 17

14

14

16

16