Page 34: of Maritime Reporter Magazine (September 15, 1980)

Read this page in Pdf, Flash or Html5 edition of September 15, 1980 Maritime Reporter Magazine

On Michigan's Upper Peninsula—

New UPSCO Shipyard

Begins Production

An entirely new shipyard, pro- grammed to build commercial tug/ barge units, is now in operation in Ontonagon, Mich.

Upper Peninsula Shipbuilding

Company (UPSCO), a privately owned firm, was formed in May of 1979 when its president, Charles

H. Kerkman, together with Rob- ert J. Rotundo and Robert D.

Fischl, saw a need for efficient vessel systems that would offer low-cost water transportation on the Great Lakes. Comprehensive transportation studies involving rail and truck traffic in the Great

Lakes area clearly indicated sav- ings to the many shippers who could use cross-lake water trans- portation as an alternative to around-the-lake rail or truck forms of shipping.

These studies showed that the integrated tug/barge concept seemed to offer the most efficient system in handling cross-lake needs on a shuttle basis. Frequent service on a closely scheduled timetable would smooth the peaks and valleys, and reduce the "dead time" during loading and unload- ing of cargoes. UPSCO feels that the integrated tug/barge concept is ideally adapted to the needs of cross-lake railroad car shuttle service between Michigan and

Wisconsin railhead ports.

The first vessels being built at the new UPSCO yard are part of an integrated tug/barge system for the State of Michigan. The initial contract with the state specifies a system comprising one tug and four barges (forebodies).

Production of the system is now under way, with deliveries planned over the next three years.

The tug in the UPSCO system is 120 feet long, powered by two

MaK 4,000-bhp turbocharged die- sel engines driving controllable- pitch propellers. The engines are designed to operate on residual fuels, providing low-cost opera- tion. Each barge will be 437 feet long with a beam of 64 feet; LOA of the tug/barge unit will be 484 feet.

The barges will be fully en- closed utilizing Navaire bow doors, and will accommodate 28 railroad cars. The mechanism to connect the tug and barge will be manu- factured under license from ACB of France.

UPSCO engaged Breit & Gar- cia, a New Orleans naval archi- tecture firm with a great deal of experience and an international reputation in the development of integrated tug/barges, to design the complete system.

Construction of the Upper Pe- ninsula Shipbuilding yard began in November 1979. In less than seven months, on June 2, 1980, vessel fabrication was started.

The main fabrication building has an area of 60,000 square feet, with an adjoining five-floor pro- duction office building. Module building is carried out under four

P&H bridge cranes, each having a span of 125 feet and 70 feet under the hook; two have a ca- pacity of 50 tons and two are 15-ton cranes. Administration, trades, warehouse, and other sup- port buildings are now under con- struction, scheduled for comple- tion by the end of this year.

Installation of the latest in steel-treatment, transport, fabri- cation, and lifting equipment en- sures the cost efficiency of UP-

SCO's operation. Major items of equipment include a Pangborn metal-processing system, the lat- est computer-automated Linde metal-cutting equipment, a high- capacity Ogden welding line, and a 750-ton Pacific press. Outside lifting will be handled by a Mani- towoc model 4100W crawler crane.

One of the major undertakings is the staffing of the company.

UPSCO is building its organiza- tion on a scheduled basis, both in the areas of management and hourly employees. Knowledge- able, experienced personnel have been brought into the company in all areas.

In cooperation with the Michi- gan Department of Labor, em- ployee training schools have been under way for several months.

Total employment during July this year reached 85 people; full- production employment level will range between 400 and 450 work- ers.

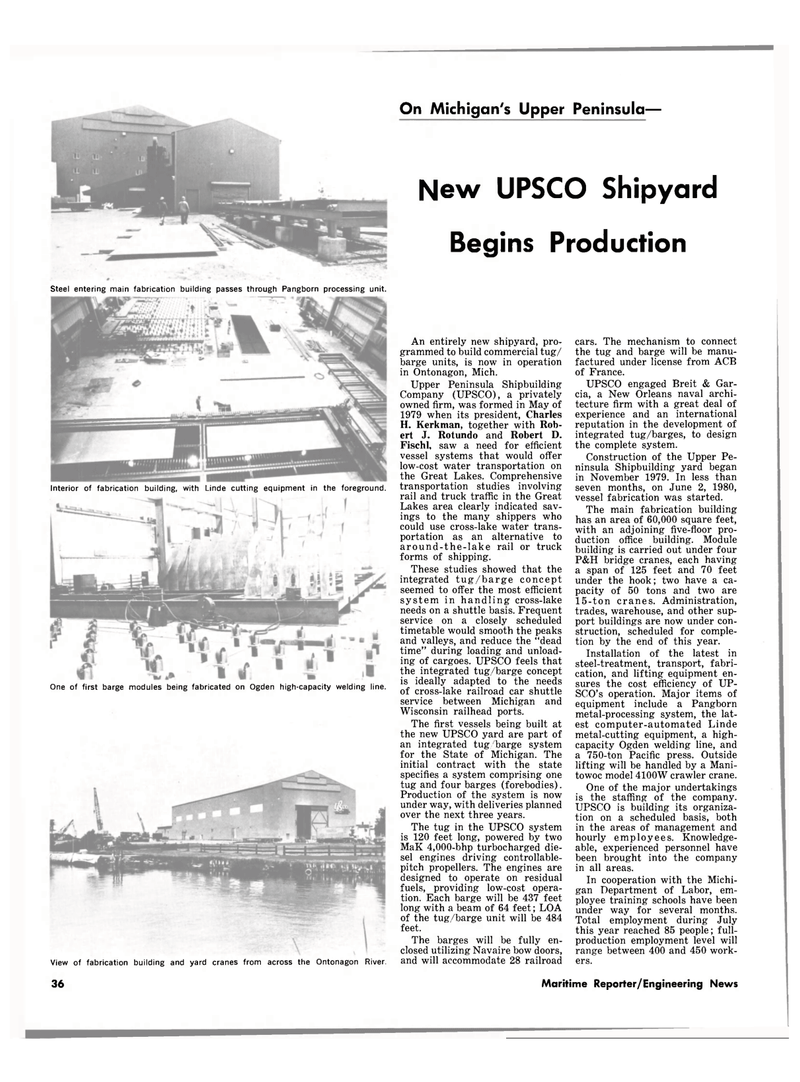

Steel entering main fabrication building passes through Pangborn processing unit.

Interior of fabrication building, with Linde cutting equipment in the foreground.

One of first barge modules being fabricated on Ogden high-capacity welding line.

View of fabrication building and yard cranes from across the Ontonagon River. 36 Maritime Reporter/Engineering News

33

33

35

35