Page 29: of Maritime Reporter Magazine (January 1981)

Read this page in Pdf, Flash or Html5 edition of January 1981 Maritime Reporter Magazine

Bergeron Enters New Product

Line With Four Tank Barges

Bergeron Industries, Inc. recently deliv- ered four tank barges from their Braith- waite, La., marine facility, marking the com- pany's entrance into a new product line.

Long a major designer and builder of deck barges, Bergeron is using this experience in tank barge construction.

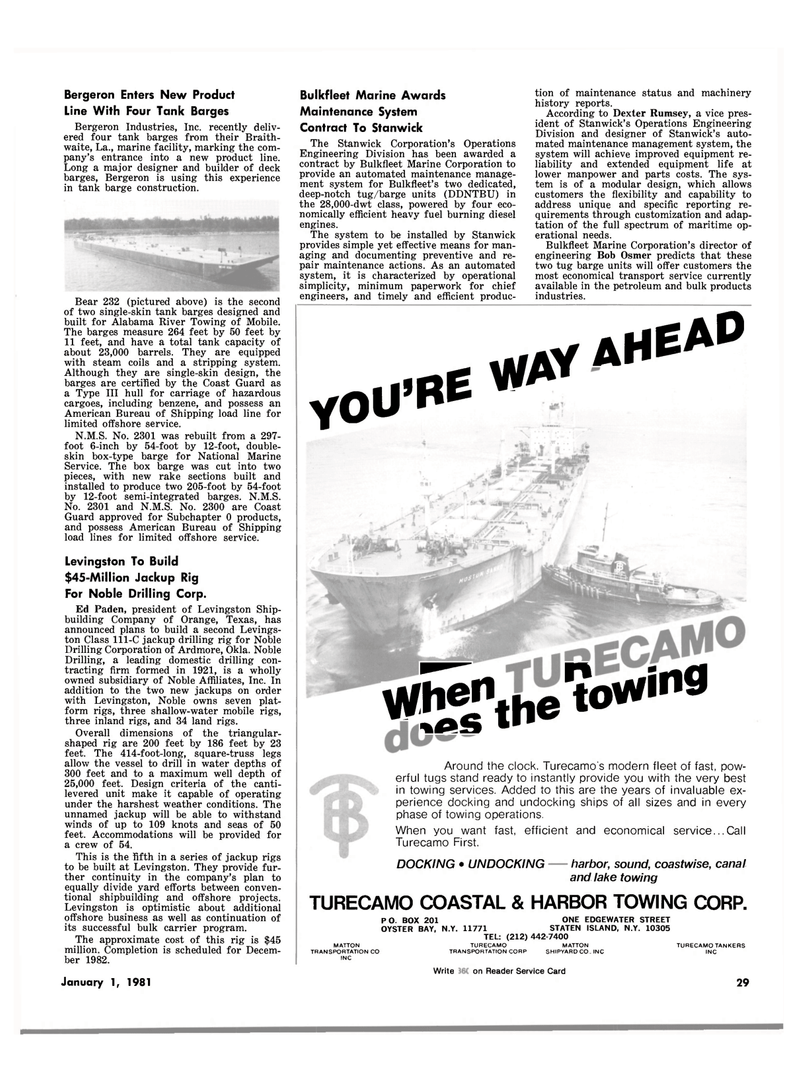

Bear 232 (pictured above) is the second of two single-skin tank barges designed and built for Alabama River Towing of Mobile.

The barges measure 264 feet by 50 feet by 11 feet, and have a total tank capacity of about 23,000 barrels. They are equipped with steam coils and a stripping system.

Although they are single-skin design, the barges are certified by the Coast Guard as a Type III hull for carriage of hazardous cargoes, including benzene, and possess an

American Bureau of Shipping load line for limited offshore service.

N.M.S. No. 2301 was rebuilt from a 297- foot 6-inch by 54-foot by 12-foot, double- skin box-type barge for National Marine

Service. The box barge was cut into two pieces, with new rake sections built and installed to produce two 205-foot by 54-foot by 12-foot semi-integrated barges. N.M.S.

No. 2301 and N.M.S. No. 2300 are Coast

Guard approved for Subchapter 0 products, and possess American Bureau of Shipping load lines for limited offshore service.

Levingston To Build $45-Million Jackup Rig

For Noble Drilling Corp.

Ed Paden, president of Levingston Ship- building Company of Orange, Texas, has announced plans to build a second Levings- ton Class 111-C jackup drilling rig for Noble

Drilling Corporation of Ardmore, Okla. Noble

Drilling, a leading domestic drilling con- tracting firm formed in 1921, is a wholly owned subsidiary of Noble Affiliates, Inc. In addition to the two new jackups on order with Levingston, Noble owns seven plat- form rigs, three shallow-water mobile rigs, three inland rigs, and 34 land rigs.

Overall dimensions of the triangular- shaped rig are 200 feet by 186 feet by 23 feet. The 414-foot-long, square-truss legs allow the vessel to drill in water depths of 300 feet and to a maximum well depth of 25,000 feet. Design criteria of the canti- levered unit make it capable of operating under the harshest weather conditions. The unnamed jackup will be able to withstand winds of up to 109 knots and seas of 50 feet. Accommodations will be provided for a crew of 54.

This is the fifth in a series of jackup rigs to be built at Levingston. They provide fur- ther continuity in the company's plan to equally divide yard efforts between conven- tional shipbuilding and offshore projects.

Levingston is optimistic about additional offshore business as well as continuation of its successful bulk carrier program.

The approximate cost of this rig is $45 million. Completion is scheduled for Decem- ber 1982.

January 1, 1981

Bulkfleet Marine Awards

Maintenance System

Contract To Stanwick

The Stanwick Corporation's Operations

Engineering Division has been awarded a contract by Bulkfleet Marine Corporation to provide an automated maintenance manage- ment system for Bulkfleet's two dedicated, deep-notch tug/barge units (DDNTBU) in the 28,000-dwt class, powered by four eco- nomically efficient heavy fuel burning diesel engines.

The system to be installed by Stanwick provides simple yet effective means for man- aging and documenting preventive and re- pair maintenance actions. As an automated system, it is characterized by operational simplicity, minimum paperwork for chief engineers, and timely and efficient produc- tion of maintenance status and machinery history reports.

According to Dexter Rumsey, a vice pres- ident of Stanwick's Operations Engineering

Division and designer of Stanwick's auto- mated maintenance management system, the system will achieve improved equipment re- liability and extended equipment life at lower manpower and parts costs. The sys- tem is of a modular design, which allows customers the flexibility and capability to address unique and specific reporting re- quirements through customization and adap- tation of the full spectrum of maritime op- erational needs.

Bulkfleet Marine Corporation's director of engineering Bob Osmer predicts that these two tug barge units will offer customers the most economical transport service currently available in the petroleum and bulk products industries.

YOU 'RE

WAV ahead

W^Tthe?oWing

Around the clock, Turecamo's modern fleet of fast, pow- erful tugs stand ready to instantly provide you with the very best in towing services. Added to this are the years of invaluable ex- perience docking and undocking ships of all sizes and in every phase of towing operations.

When you want fast, efficient and economical service...Call

Turecamo First.

DOCKING • UNDOCKING • harbor, sound, coastwise, canal and lake towing

TURECAMO COASTAL & HARBOR TOWING CORP.

PO. BOX 201 ONE EDGEWATER STREET

OYSTER BAY, N.Y. 11771 STATEN ISLAND, N.Y. 10305

TEL: (212) 442-7400

MATTON

TRANSPORTATION CO

INC

TURECAMO

TRANSPORTATION CORP

MATTON

SHIPYARD CO . INC

TURECAMO TANKERS

INC

Write 257 on Reader Service Card 29

28

28

30

30