Page 38: of Maritime Reporter Magazine (January 1981)

Read this page in Pdf, Flash or Html5 edition of January 1981 Maritime Reporter Magazine

Technology Survey

Of Major U.S. Yards (continued from page 36) the survey when all the surveyors met and exchanged annotated da- ta sheets. Initially, each surveyor assigned a technology level to each element he surveyed. When the data sheets were exchanged with the counterpart surveyor on the other team, the level assign- ments were withheld and the counterpart surveyor read the notes and made his own level as- signments. Then, the two survey- ors compared notes and reached agreement on the level assign- ments. This was done between the three pairs of surveyors that made up the two teams. It turned out that the surveyors were in agreement at least 90 percent of the time.

The fourth and final step took place in England. During the process of comparing U.S. ship- yards with foreign counterparts, each level assignment was re- viewed using the surveyors' notes with the same staff engineers who conducted the workshop so as to assure consistency with the APA survey of the foreign shipyards.

The selection of foreign ship- yards took into account all the information contained in the de- scriptions of the U.S. shipyards provided by MEL. For all the for- eign shipyards, levels of technol- ogy have been assigned in accord- ance with the same standards by which the U.S. shipyards were judged. In half of the shipyards,

APA had conducted a full survey of facilities, equipment, technol- ogy and methods. For the re- maining shipyards, senior APA staff members had spent a min- imum of two manweeks in each shipyard during the past three years. In selecting comparable foreign shipyards the following criteria were used: work experi- ence past and present, maximum ship length, number of employees, physical size, and type of ship- yard, that is, new or redevel- oped. A total of 25 shipyards rep- resenting six countries — Japan,

Germany, France, Denmark, Swe- den and the U.K.—were selected.

Comparison and Analysis

The approach was to go from the broad to the detail level, from the eight categories to the 70 elements. More specifically: 1. The average technology lev- els of the U.S. and foreign ship- yards for each of the eight cate- gories are presented in four dif- ferent ways to provide a broad perspective of the differences found. 2. Certain of the 70 elements are identified as critical and are presented in some detail. 3. Areas in which the U.S. ship- yards measure favorably are iden- tified. 4. Some of the causes of tech- nology level differences are iden- tified.

The data developed during this technology survey provide a wealth of detail for comparison and analysis. Some of the infor- mation presented in this paper shows the following:

The U.S. shipyards lead the foreign shipyards only in Cate- gory B, Outfit and Production

Stores. Average technology lev- els are the same for Category H,

Organization and Operating Sys- tems. For the remaining six cat- egories, U.S. shipyard technology levels are lower on the average, the greatest disparities arising with Categories C and F, Other

Preerection Activities and Envi- ronment and Amenities, respec- tively. The first four categories (A-D) cover the technology em- ployed in the "hands-on" man- power-intensive part of a ship- building project. Two of the re- maining four categories primar- ily concentrate on the workplace and working conditions. The last two deal with the engineering and systems elements which direct and control the hands-on work.

In actual fact, these last four categories are supportive since their purpose is to make it pos- sible for the workforce to com- plete the ship in as short a time period as possible with minimum expenditure of manpower.

The shortfalls in three of the (continued on page 40)

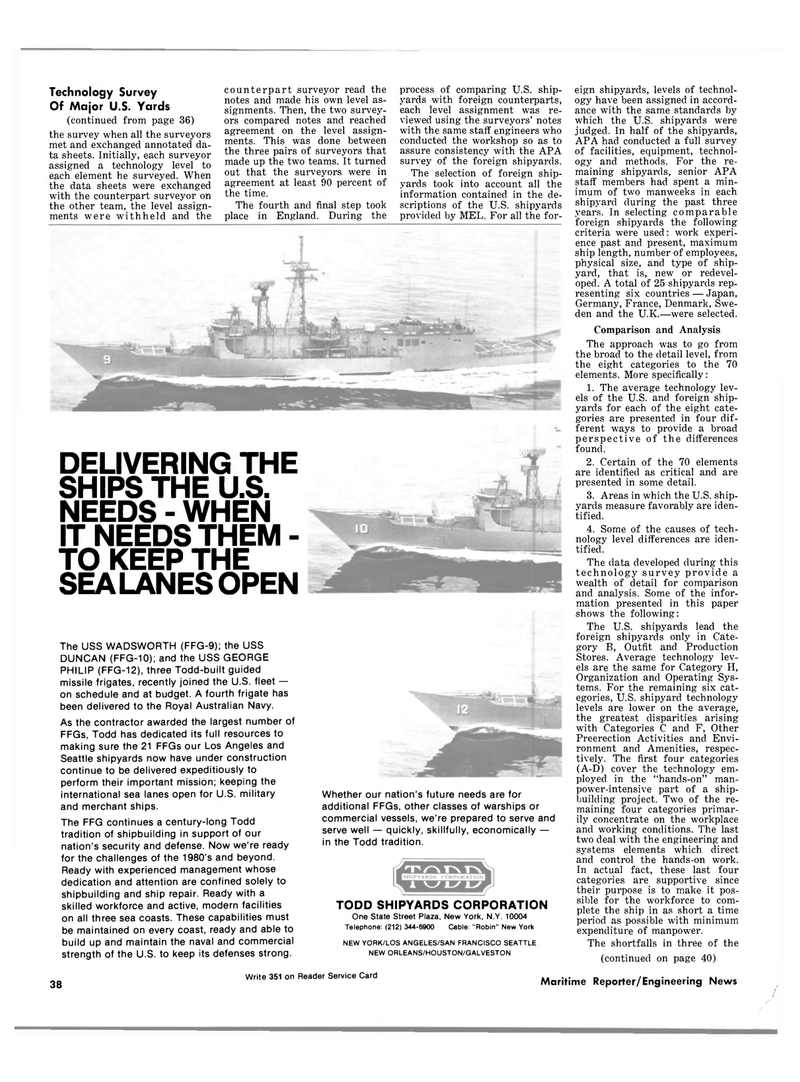

The USS WADSWORTH (FFG-9); the USS

DUNCAN (FFG-10); and the USS GEORGE

PHILIP (FFG-12), three Todd-built guided missile frigates, recently joined the U.S. fleet — on schedule and at budget. A fourth frigate has been delivered to the Royal Australian Navy.

As the contractor awarded the largest number of

FFGs, Todd has dedicated its full resources to making sure the 21 FFGs our Los Angeles and

Seattle shipyards now have under construction continue to be delivered expeditiously to perform their important mission; keeping the international sea lanes open for U.S. military and merchant ships.

The FFG continues a century-long Todd tradition of shipbuilding in support of our nation's security and defense. Now we're ready for the challenges of the 1980's and beyond.

Ready with experienced management whose dedication and attention are confined solely to shipbuilding and ship repair. Ready with a skilled workforce and active, modern facilities on all three sea coasts. These capabilities must be maintained on every coast, ready and able to build up and maintain the naval and commercial strength of the U.S. to keep its defenses strong.

Whether our nation's future needs are for additional FFGs, other classes of warships or commercial vessels, we're prepared to serve and serve well — quickly, skillfully, economically — in the Todd tradition.

TODD SHIPYARDS CORPORATION

One State Street Plaza, New York, N.Y. 10004

Telephone: (212) 344-6900 Cable: "Robin" New York

NEW YORK/LOS ANGELES/SAN FRANCISCO SEATTLE

NEW ORLEANS/HOUSTON/GALVESTON

DELIVERING THE SHIPS THE U.S.

NEEDS - WHEN IT NEEDS THEM -

TO KEEP THE SEA LANES OPEN 38

Write 351 on Reader Service Card Maritime Reporter/Engineering News

37

37

39

39