Page 22: of Maritime Reporter Magazine (September 1981)

Read this page in Pdf, Flash or Html5 edition of September 1981 Maritime Reporter Magazine

CARGO

HANDLING

EQUIPMENT

Latest offerings from the world s leading manufacturers

Time being money for owners and operators of vessels and off- shore rigs, any speed-up in cargo handling produces cost savings, in many cases substantial ones.

Recognizing this, manufacturers of all types of equipment used in these operations have responded with ever more sophisticated gear, from high-speed automated cranes to polymer coatings for the hoppers of bulk carriers.

We asked the major designers and manufacturers of cargo han- dling equipment to tell us about their latest developments as ivell as their proven products. The fol- lowing review on cargo handling is based on the replies we had received as we went to press.

Brochures and literature de- scribing all of the products man- ufactured by the companies fea- tured in this article are available

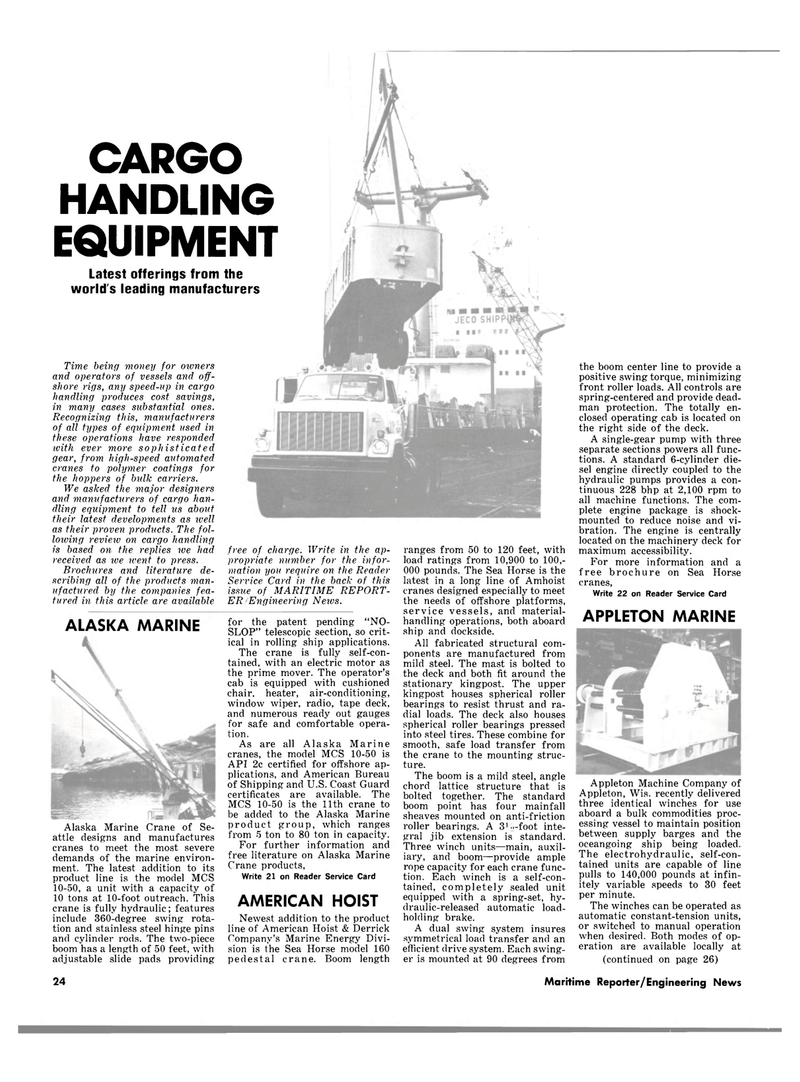

ALASKA MARINE

Alaska Marine Crane of Se- attle designs and manufactures cranes to meet the most severe demands of the marine environ- ment. The latest addition to its product line is the model MCS 10-50, a unit with a capacity of 10 tons at 10-foot outreach. This crane is fully hydraulic; features include 360-degree swing rota- tion and stainless steel hinge pins and cylinder rods. The two-piece boom has a length of 50 feet, with adjustable slide pads providing free of charge. Write in the ap- propriate number for the infor- mation you require on the Reader

Service Card in the back of this issue of MARITIME REPORT-

ER Engineering News. for the patent pending "NO-

SLOP" telescopic section, so crit- ical in rolling ship applications.

The crane is fully self-con- tained, with an electric motor as the prime mover. The operator's cab is equipped with cushioned chair, heater, air-conditioning, window wiper, radio, tape deck, and numerous ready out gauges for safe and comfortable opera- tion.

As are all Alaska Marine cranes, the model MCS 10-50 is

API 2c certified for offshore ap- plications, and American Bureau of Shipping and U.S. Coast Guard certificates are available. The

MCS 10-50 is the 11th crane to be added to the Alaska Marine product group, which ranges from 5 ton to 80 ton in capacity.

For further information and free literature on Alaska Marine

Crane products,

Write 21 on Reader Service Card

AMERICAN HOIST

Newest addition to the product line of American Hoist & Derrick

Company's Marine Energy Divi- sion is the Sea Horse model 160 pedestal crane. Boom length ranges from 50 to 120 feet, with load ratings from 10,900 to 100,- 000 pounds. The Sea Horse is the latest in a long line of Amhoist cranes designed especially to meet the needs of offshore platforms, service vessels, and material- handling operations, both aboard ship and dockside.

All fabricated structural com- ponents are manufactured from mild steel. The mast is bolted to the deck and both fit around the stationary kingpost. The upper kingpost houses spherical roller bearings to resist thrust and ra- dial loads. The deck also houses spherical roller bearings pressed into steel tires. These combine for smooth, safe load transfer from the crane to the mounting struc- ture.

The boom is a mild steel, angle chord lattice structure that is bolted together. The standard boom point has four mainfall sheaves mounted on anti-friction roller bearings. A 3'--foot inte- gral jib extension is standard.

Three winch units—main, auxil- iary, and boom—provide ample rope capacity for each crane func- tion. Each winch is a self-con- tained, completely sealed unit equipped with a spring-set, hy- draulic-released automatic load- holding brake.

A dual swing system insures symmetrical load transfer and an efficient drive system. Each swing- er is mounted at 90 degrees from the boom center line to provide a positive swing torque, minimizing front roller loads. All controls are spring-centered and provide dead- man protection. The totally en- closed operating cab is located on the right side of the deck.

A single-gear pump with three separate sections powers all func- tions. A standard 6-cylinder die- sel engine directly coupled to the hydraulic pumps provides a con- tinuous 228 bhp at 2,100 rpm to all machine functions. The com- plete engine package is shock- mounted to reduce noise and vi- bration. The engine is centrally located on the machinery deck for maximum accessibility.

For more information and a free brochure on Sea Horse cranes,

Write 22 on Reader Service Card

APPLETON MARINE

Appleton Machine Company of

Appleton, Wis. recently delivered three identical winches for use aboard a bulk commodities proc- essing vessel to maintain position between supply barges and the oceangoing ship being loaded.

The electrohydraulic, self-con- tained units are capable of line pulls to 140,000 pounds at infin- itely variable speeds to 30 feet per minute.

The winches can be operated as automatic constant-tension units, or switched to manual operation when desired. Both modes of op- eration are available locally at (continued on page 26) 24 Maritime Reporter/Engineering News

21

21

23

23