Page 41: of Maritime Reporter Magazine (January 1984)

Read this page in Pdf, Flash or Html5 edition of January 1984 Maritime Reporter Magazine

mwmi

The North Sounder is designed to recover 90 percent of an oil spill at rates up to 500 gpm. Its on- board recovered oil capacity is 12,000 gallons. When operating in the oil-spill recovery mode, the vessel's bow opens to reveal an es- calator-like ramp leading from un- der the water surface and into the mid-hull area of the boat.

Several design changes devel- oped by the Clean Sound staff have been incorporated into the

North Sounder. The most signifi- cant is an improved method of re- covering oily debris. This system was designed to cope with mate- rials such as logs, branches, kelp, eel grass, and other floating debris.

The North Sounder was de- signed by JBF Scientific Corpora- tion of Wilmington, Mass. JBF has designed more than 100 oil-skim- ming vessels, including 50 harbor skimmers for the U.S. Navy. Clean

Sound's new skimmer is a JBF model DIP 5001A.

Because of her traditional hull design, the vessel can respond to oil spills at speeds up to 10.6 knots. During normal skimming operations, she runs at 1 to 2 knots in conditions up to Sea State 3. The vessel can work alone or with long containment booms at- tached to the bow in a "V" config- uration to funnel oil slicks to the recovery system. (continued on page 42)

Deck equipment includes two

McElroy towing winches and an

HBL anchor windlass. Carlisle &

Finch supplied the searchlights,

Kalhenberg the air horns, and

Hubbel the running and naviga- tion lights.

The Nicor Clipper is classed by the American Bureau of Shipping and certified by the U.S. Coast

Guard. 0 « 0.

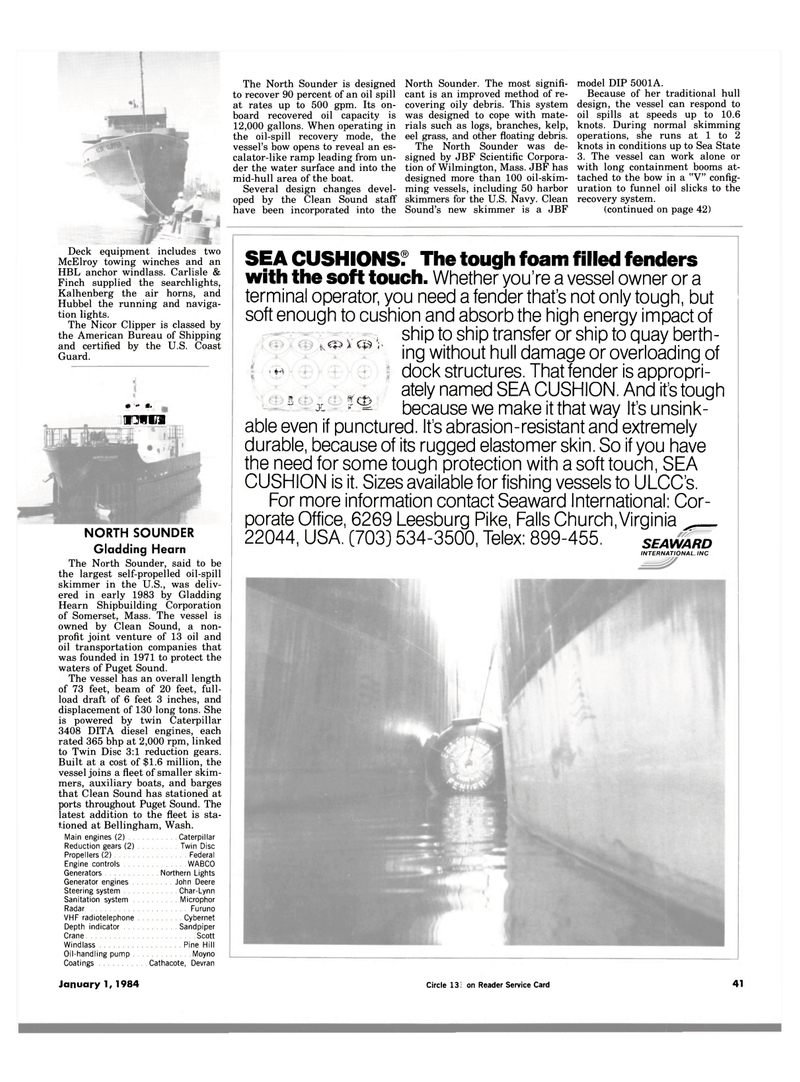

NORTH SOUNDER

Gladding Hearn

The North Sounder, said to be the largest self-propelled oil-spill skimmer in the U.S., was deliv- ered in early 1983 by Gladding

Hearn Shipbuilding Corporation of Somerset, Mass. The vessel is owned by Clean Sound, a non- profit joint venture of 13 oil and oil transportation companies that was founded in 1971 to protect the waters of Puget Sound.

The vessel has an overall length of 73 feet, beam of 20 feet, full- load draft of 6 feet 3 inches, and displacement of 130 long tons. She is powered by twin Caterpillar 3408 DITA diesel engines, each rated 365 bhp at 2,000 rpm, linked to Twin Disc 3:1 reduction gears.

Built at a cost of $1.6 million, the vessel joins a fleet of smaller skim- mers, auxiliary boats, and barges that Clean Sound has stationed at ports throughout Puget Sound. The latest addition to the fleet is sta- tioned at Bellingham, Wash.

Main engines (2) Caterpillar

Reduction gears (2) Twin Disc

Propellers (2) Federal

Engine controls WABCO

Generators Northern Lights

Generator engines John Deere

Steering system Char-Lynn

Sanitation system Microphor

Radar Furuno

VHF radiotelephone Cybernet

Depth indicator Sandpiper

Crane Scot

Windlass Pine Hill

Oil-handling pump Moyno

Coatings Cathacote, Devran

:[ CP ¥ Q |

- SEA CUSHIONS? The tough foam filled fenders

with the soft touch. Whether you're a vessel owner or a

terminal operator, you need a fender that's not only tough, but

soft enough to cushion and absorb the high energy impact of

ship to ship transfer or ship to quay berth-

ing without hull damage or overloading of

dock structures. That fender is appropri-

ately named SEA CUSHION. And it's tough

because we make it that way It's unsink-

able even if punctured. It's abrasion-resistant and extremely

durable, because of its rugged elastomer skin. So if you have

the need for some tough protection with a soft touch, SEA

CUSHION is it. Sizes available for fishing vessels to ULCC's.

For more information contact Seaward International: Cor-

porate Office, 6269 Leesburg Pike, Falls Church, Virginia ^

22044, USA. (703) 534-3500, Telex: 899-455. SEAWARD

INTERNATIONAL. INC

i x % eg

January 1, 1984 Circle 136 on Reader Service Card 41

40

40

42

42