Page 67: of Maritime Reporter Magazine (April 1984)

Read this page in Pdf, Flash or Html5 edition of April 1984 Maritime Reporter Magazine

Worthington Offers New

Cast Iron Pump Line — Literature Available

A general-purpose line of effi- cient end-suction pumps with ca- pacities to 1,200 gpm is being of- fered by Worthington through its national network of independent distributors and direct-sales per- sonnel.

The cast iron pumps, designated as the D-800 line, are available in 19 sizes, frame-mounted or close- coupled. The pumps are designed for minimum operating and main- tenance costs.

Features include a bell-shaped mechanical seal cover to provide improved mechanical seal life.

Frame-mounted pump bearings are conservatively designed and main- tenance-free, being sealed for life and pre-lubricated. Other advan- tages cited for the pump include back-pullout, allowing complete access to pump internals without disturbing system piping; integral adapter seal cover for added pump rigidity and fewer internal compo- nents; dry rabbet fit at the casing joint to eliminate internal corro- sion and to aid in pump disassem- bly when being repaired; and top centerline discharge casings to simplify system piping and remove stress on pump bearing frame.

Standard materials of construc- tion include a high-grade cast iron casting with precision bronze vac- uum die-cast impellers of enclosed design. High-strength steel shafts will be protected at the mechani- cal seal area by renewable bronze or 416 SS sleeves. An all-cast-iron fitted pump is also available.

For free literature and specifi- cations on the D-800 line,

Circle 12 on Reader Service Card

Management Appointments

Announced By Crowley's

Caribbean Division

Four key appointments have been made in Crowley Maritime

Corporation's Caribbean Division, according to a recent announce- ment by Robert G. Homan, Jack- sonville, Fla., Crowley senior vice president and general manager of the division.

David N. Messer has been ap- pointed to the new position of vice president, common carrier serv- ices, based in Jacksonville. He has held a number of positions during his six years with the company in- cluding, most recently, vice presi- dent, market development. He was instrumental in development of the division's U.S. Northeast roll- on/roll-off service to the Caribbean.

Gene A. Tonsager has been named assistant vice president, marketing, replacing Mr. Messer in responsibility for market devel- opment as well as maintaining his previous duties as assistant vice president, pricing. Mr. Tonsager, who joined the company last June, is based in Jacksonville.

John S. Hollett has been ap- pointed director of South Atlantic common carrier services, based in

Jacksonville. He was formerly di- rector of marketing for Crowley's

Caribbean Division contract trans- portation services, and has been with the Crowley organization for seven years.

Jose A. Amadeo has been named director of Caribbean Serv- ices, based in San Juan, Puerto

Rico, overseeing Crowley opera- tions in RO/RO services to the

U.S. mainland as well as to other destinations in the Caribbean, and contract tug and barge services.

Mr. Amadeo joined the company in 1982. Prior to this appointment he was director of marketing and administration for Trailer Marine

Transport Corporation in the

Caribbean.

MURDOCHS ROPE TENSION DAMPER

HELPS YOU RIDE OUT THE ROUGH SEAS

SAFER, MORE SECURELY.

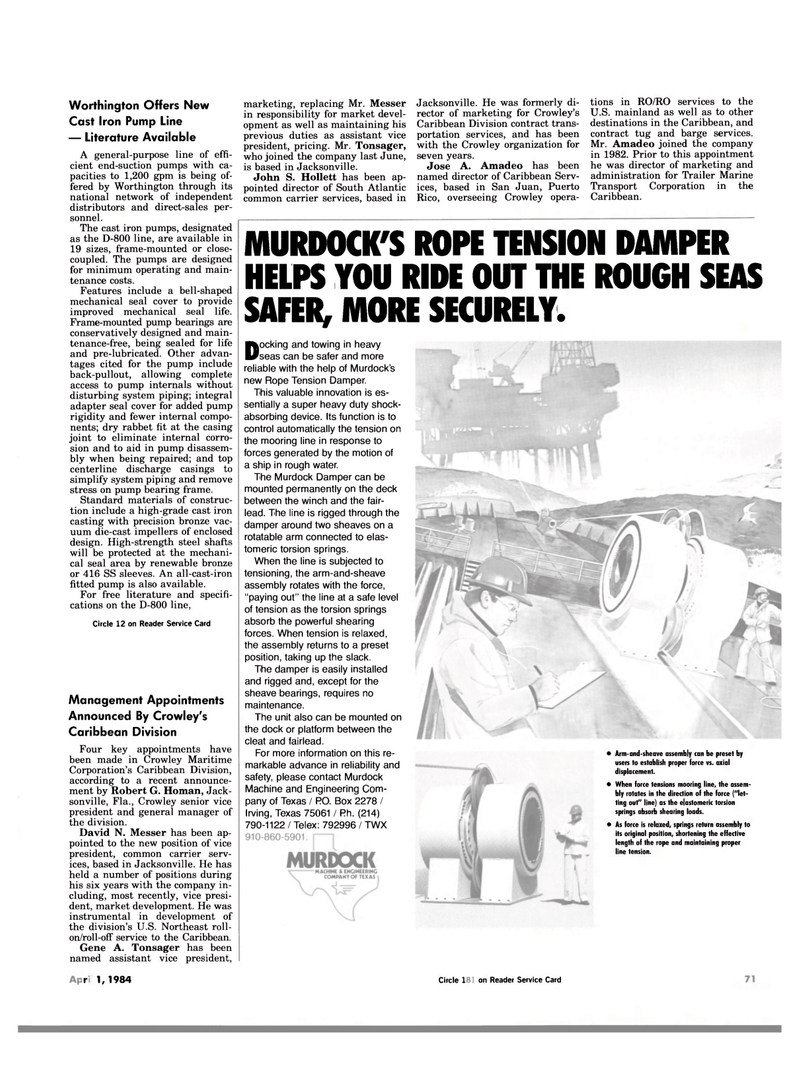

Docking and towing in heavy seas can be safer and more reliable with the help of Murdock's new Rope Tension Damper.

This valuable innovation is es- sentially a super heavy duty shock- absorbing device. Its function is to control automatically the tension on the mooring line in response to forces generated by the motion of a ship in rough water.

The Murdock Damper can be mounted permanently on the deck between the winch and the fair- lead. The line is rigged through the damper around two sheaves on a rotatable arm connected to elas- tomeric torsion springs.

When the line is subjected to tensioning, the arm-and-sheave assembly rotates with the force, "paying out" the line at a safe level of tension as the torsion springs absorb the powerful shearing forces. When tension is relaxed, the assembly returns to a preset position, taking up the slack.

The damper is easily installed and rigged and, except for the sheave bearings, requires no maintenance.

The unit also can be mounted on the dock or platform between the cleat and fairlead.

For more information on this re- markable advance in reliability and safety, please contact Murdock

Machine and Engineering Com- pany of Texas / PO. Box 2278 /

Irving, Texas 75061 / Ph. (214) 790-1122 / Telex: 792996 / TWX • Arm-and-sheave assembly can be preset by users to establish proper force vs. axial displacement. • When force tensions mooring line, the assem- bly rotates in the direction of the force ("let- ting out" line) as the elastomeric torsion springs absorb shearing loads. • As force is relaxed, springs return assembly to its original position, shortening the effective length of the rope and maintaining proper line tension.

March 15, 1984 Circle 132 on Reader Service Card 69

66

66

68

68