Page 28: of Maritime Reporter Magazine (October 1984)

Read this page in Pdf, Flash or Html5 edition of October 1984 Maritime Reporter Magazine

MWPV BUCCANEER —A Review—

Faster turnaround in port means increased profits for all vessel oper- ators. To meet that need, designers and manufacturers of cargo han- dling equipment and access and stowage systems continue to im- prove their products and to intro- duce new, more efficient cargo gear and deck machinery.

The editors of MR/EN asked the manufacturers of cargo-handling and other deck machinery and fit- tings to tell us about their product lines and their latest developments.

The review that follows is based upon the replies we had received at press time.

Literature describing all of the equipment featured in this review is available free of charge from the manufacturers.

FOR MORE INFORMATION

If you wish to receive additional information and literature on any of the companies and products fea- tured in this article, circle the ap-

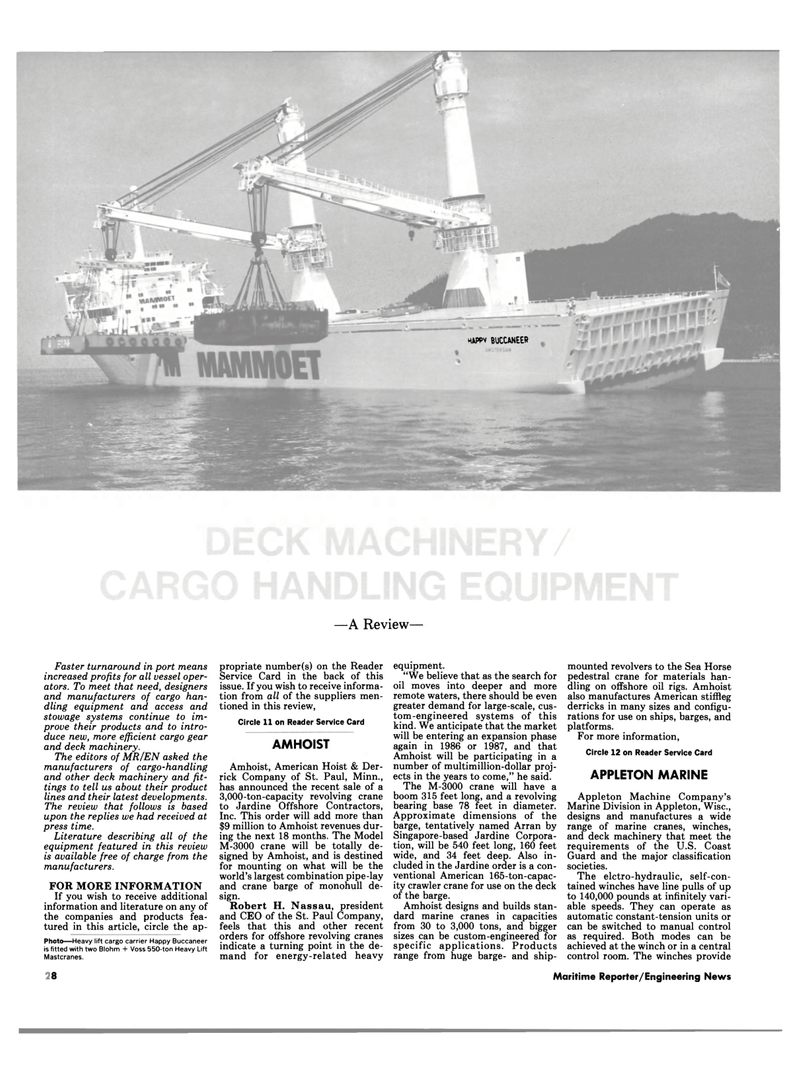

Photo—Heavy lift cargo carrier Happy Buccaneer is fitted with two Blohm + Voss 550-ton Heavy Lift

Mastcranes. propriate number(s) on the Reader

Service Card in the back of this issue. If you wish to receive informa- tion from all of the suppliers men- tioned in this review,

Circle 11 on Reader Service Card

AMHOIST

Amhoist, American Hoist & Der- rick Company of St. Paul, Minn., has announced the recent sale of a 3,000-ton-capacity revolving crane to Jardine Offshore Contractors,

Inc. This order will add more than $9 million to Amhoist revenues dur- ing the next 18 months. The Model

M-3000 crane will be totally de- signed by Amhoist, and is destined for mounting on what will be the world's largest combination pipe-lay and crane barge of monohull de- sign.

Robert H. Nassau, president and CEO of the St. Paul Company, feels that this and other recent orders for offshore revolving cranes indicate a turning point in the de- mand for energy-related heavy equipment. "We believe that as the search for oil moves into deeper and more remote waters, there should be even greater demand for large-scale, cus- tom-engineered systems of this kind. We anticipate that the market will be entering an expansion phase again in 1986 or 1987, and that

Amhoist will be participating in a number of multimillion-dollar proj- ects in the years to come," he said.

The M-3000 crane will have a boom 315 feet long, and a revolving bearing base 78 feet in diameter.

Approximate dimensions of the barge, tentatively named Arran by

Singapore-based Jardine Corpora- tion, will be 540 feet long, 160 feet wide, and 34 feet deep. Also in- cluded in the Jardine order is a con- ventional American 165-ton-capac- ity crawler crane for use on the deck of the barge.

Amhoist designs and builds stan- dard marine cranes in capacities from 30 to 3,000 tons, and bigger sizes can be custom-engineered for specific applications. Products range from huge barge- and ship- mounted revolvers to the Sea Horse pedestral crane for materials han- dling on offshore oil rigs. Amhoist also manufactures American stiffleg derricks in many sizes and configu- rations for use on ships, barges, and platforms.

For more information,

Circle 12 on Reader Service Card

APPLETON MARINE

Appleton Machine Company's

Marine Division in Appleton, Wise., designs and manufactures a wide range of marine cranes, winches, and deck machinery that meet the requirements of the U.S. Coast

Guard and the major classification societies.

The elctro-hydraulic, self-con- tained winches have line pulls of up to 140,000 pounds at infinitely vari- able speeds. They can operate as automatic constant-tension units or can be switched to manual control as required. Both modes can be achieved at the winch or in a central control room. The winches provide 18 Maritime Reporter/Engineering News

27

27

29

29