Page 18: of Maritime Reporter Magazine (January 15, 1986)

Read this page in Pdf, Flash or Html5 edition of January 15, 1986 Maritime Reporter Magazine

Optimizing Efficiency Levels

Of Boiler Feed Turbo Pumps

By John J. Amicucci*

The majority of steam-driven ships now in service were built in an era of low fuel oil prices, with their steam plants designed at or near maximum performance ratings. In those bygone days, operating a ship at lower horsepower was not a prac- tical consideration. However, with the escalation of fuel oil prices dur- ing the past decade or so, the need exists for slower steaming to reduce fuel consumption as much as possi- ble. Derating of the boiler feed pump is a major, positive step in this direction.

The boiler feed pump is totally amenable to efficiency improve- ment through derating, and rela- tively easy to achieve (Figure 1). As about 90 percent of all steam-driven tankers and containerships employ either DEB-16 or DEB-22 Coffin® feed pumps, it is a simple matter for the installer to obtain the needed parts from the original equipment manufacturer, either directly or through a marine agent. The marine agent could also provide whatever field service that may be needed.

The less steam it takes to run the boiler feed pump, the less fuel is burned. Using a standard two-stage

DEB-16 turbo pump operating at 532 hp, even a 10-percent saving effected through derating would be the equivalent of not having to run a 50-hp motor. All that the service specialist or the ship's engineer needs to know are the flow and pres- sure readings to begin the derating process. If, for example, the present pump steam flow is 900 gallons per minute, and 500 gpm is calculated to be an efficient level, the conver- sion might entail a new impeller, diffuser, diaphragm, or perhaps all of these parts.

Coffin Turbo Pump

Steam Consumption Comparison 10,000 9.000 8.000 ; 7,000 ! 6,000 ! 5,000 j 4,000 5 3,000 2,000

Feed Pump Capacity Versus

Vessel Speed 13 14 IS 16 25 SO 7S 100 125 150 175

M'/HR

Feed Pump Capacit,

Figure 1.

Whenever a reduction in vessel speed is indicated, the steam plant and feed pumps operate at a lower capacity, and generally at lower effi- ciency. The reduction is such that exhaust steam from the feed pump normally returned to the deaerator tank goes back to the condenser and is wasted. The amount of water a feed pump must deliver to the boiler *Mr. Amicucci is service manager, FMC

Coffin Pump, Englewood, N.J.

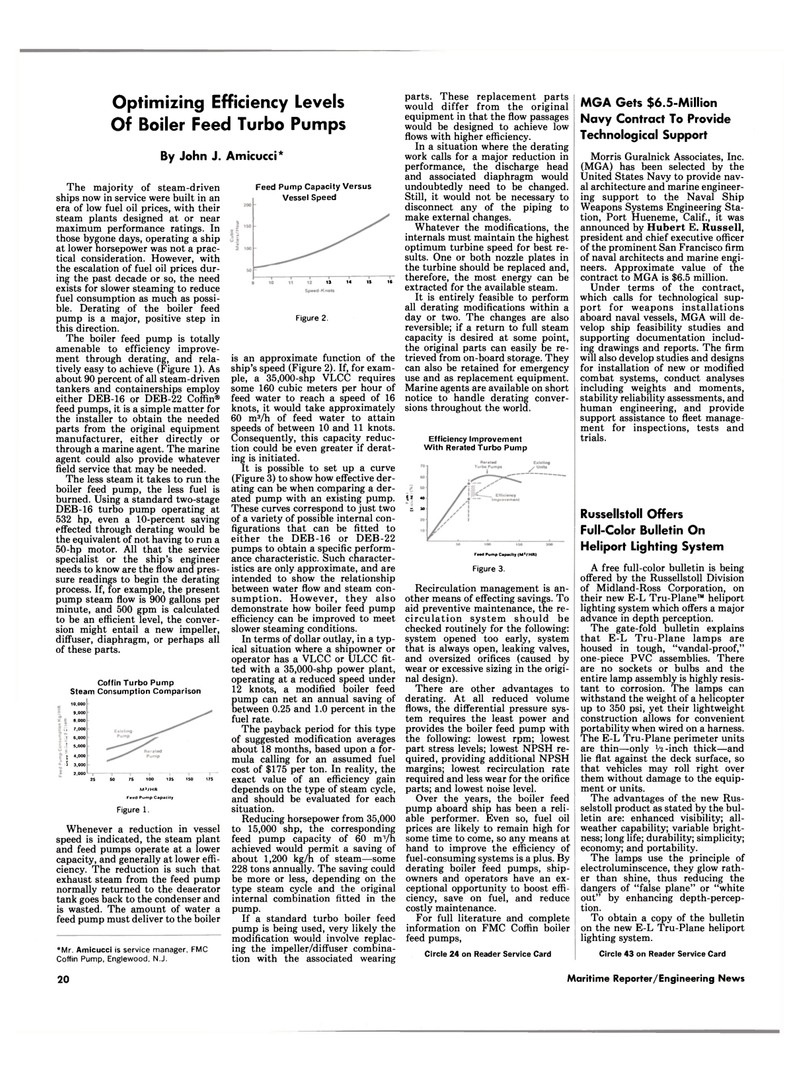

Figure 2. is an approximate function of the ship's speed (Figure 2). If, for exam- ple, a 35,000-shp VLCC requires some 160 cubic meters per hour of feed water to reach a speed of 16 knots, it would take approximately 60 m3/h of feed water to attain speeds of between 10 and 11 knots.

Consequently, this capacity reduc- tion could be even greater if derat- ing is initiated.

It is possible to set up a curve (Figure 3) to show how effective der- ating can be when comparing a der- ated pump with an existing pump.

These curves correspond to just two of a variety of possible internal con- figurations that can be fitted to either the DEB-16 or DEB-22 pumps to obtain a specific perform- ance characteristic. Such character- istics are only approximate, and are intended to show the relationship between water flow and steam con- sumption. However, they also demonstrate how boiler feed pump efficiency can be improved to meet slower steaming conditions.

In terms of dollar outlay, in a typ- ical situation where a shipowner or operator has a VLCC or ULCC fit- ted with a 35,000-shp power plant, operating at a reduced speed under 12 knots, a modified boiler feed pump can net an annual saving of between 0.25 and 1.0 percent in the fuel rate.

The payback period for this type of suggested modification averages about 18 months, based upon a for- mula calling for an assumed fuel cost of $175 per ton. In reality, the exact value of an efficiency gain depends on the type of steam cycle, and should be evaluated for each situation.

Reducing horsepower from 35,000 to 15,000 shp, the corresponding feed pump capacity of 60 m'5/h achieved would permit a saving of about 1,200 kg/h of steam—some 228 tons annually. The saving could be more or less, depending on the type steam cycle and the original internal combination fitted in the pump.

If a standard turbo boiler feed pump is being used, very likely the modification would involve replac- ing the impeller/diffuser combina- tion with the associated wearing parts. These replacement parts would differ from the original equipment in that the flow passages would be designed to achieve low flows with higher efficiency.

In a situation where the derating work calls for a major reduction in performance, the discharge head and associated diaphragm would undoubtedly need to be changed.

Still, it would not be necessary to disconnect any of the piping to make external changes.

Whatever the modifications, the internals must maintain the highest optimum turbine speed for best re- sults. One or both nozzle plates in the turbine should be replaced and, therefore, the most energy can be extracted for the available steam.

It is entirely feasible to perform all derating modifications within a day or two. The changes are also reversible; if a return to full steam capacity is desired at some point, the original parts can easily be re- trieved from on-board storage. They can also be retained for emergency use and as replacement equipment.

Marine agents are available on short notice to handle derating conver- sions throughout the world.

Efficiency Improvement

With Rerated Turbo Pump | i 40 z 30

Feed Pump Capecll, (M '/ HR)

Figure 3.

Recirculation management is an- other means of effecting savings. To aid preventive maintenance, the re- circulation system should be checked routinely for the following: system opened too early, system that is always open, leaking valves, and oversized orifices (caused by wear or excessive sizing in the origi- nal design).

There are other advantages to derating. At all reduced volume flows, the differential pressure sys- tem requires the least power and provides the boiler feed pump with the following: lowest rpm; lowest part stress levels; lowest NPSH re- quired, providing additional NPSH margins; lowest recirculation rate required and less wear for the orifice parts; and lowest noise level.

Over the years, the boiler feed pump aboard ship has been a reli- able performer. Even so, fuel oil prices are likely to remain high for some time to come, so any means at hand to improve the efficiency of fuel-consuming systems is a plus. By derating boiler feed pumps, ship- owners and operators have an ex- ceptional opportunity to boost effi- ciency, save on fuel, and reduce costly maintenance.

For full literature and complete information on FMC Coffin boiler feed pumps,

Circle 24 on Reader Service Card

MGA Gets $6.5-Million

Navy Contract To Provide

Technological Support

Morris Guralnick Associates, Inc. (MGA) has been selected by the

United States Navy to provide nav- al architecture and marine engineer- ing support to the Naval Ship

Weapons Systems Engineering Sta- tion, Port Hueneme, Calif., it was announced by Hubert E. Russell, president and chief executive officer of the prominent San Francisco firm of naval architects and marine engi- neers. Approximate value of the contract to MGA is $6.5 million.

Under terms of the contract, which calls for technological sup- port for weapons installations aboard naval vessels, MGA will de- velop ship feasibility studies and supporting documentation includ- ing drawings and reports. The firm will also develop studies and designs for installation of new or modified combat systems, conduct analyses including weights and moments, stability reliability assessments, and human engineering, and provide support assistance to fleet manage- ment for inspections, tests and trials.

Russellstoll Offers

Full-Color Bulletin On

Heliport Lighting System

A free full-color bulletin is being offered by the Russellstoll Division of Midland-Ross Corporation, on their new E-L Tru-Plane™ heliport lighting system which offers a major advance in depth perception.

The gate-fold bulletin explains that E-L Tru-Plane lamps are housed in tough, "vandal-proof," one-piece PVC assemblies. There are no sockets or bulbs and the entire lamp assembly is highly resis- tant to corrosion. The lamps can withstand the weight of a helicopter up to 350 psi, yet their lightweight construction allows for convenient portability when wired on a harness.

The E-L Tru-Plane perimeter units are thin—only V2-inch thick—and lie flat against the deck surface, so that vehicles may roll right over them without damage to the equip- ment or units.

The advantages of the new Rus- selstoll product as stated by the bul- letin are: enhanced visibility; all- weather capability; variable bright- ness; long life; durability; simplicity; economy; and portability.

The lamps use the principle of electroluminscence, they glow rath- er than shine, thus reducing the dangers of "false plane" or "white out" by enhancing depth-percep- tion.

To obtain a copy of the bulletin on the new E-L Tru-Plane heliport lighting system.

Circle 43 on Reader Service Card 20 Maritime Reporter/Engineering News

17

17

19

19