Page 8: of Maritime Reporter Magazine (August 1986)

Read this page in Pdf, Flash or Html5 edition of August 1986 Maritime Reporter Magazine

Nor Fishing 86 Rishaug Maskin Robertson Tritech D-330 E-407

Saba Molnlycke, Storforbruker D-304 (continued) Sabb Motor U-639

Kvaerner Kulde F-548 Sarpsborg Papp, Div. Kartong D-332

Landteknikk C-214 Scanmar E-412

Langsten Slip & Batbyggeri A-17 Scanmarin C-215

Lehmkuhl Radiosystemer F-546 Scanvekt-Avery D-309

Lehmkuhl Storkjokken F-545 Sea-Tek F-539

Liaaen Helix F-524 Seatronic C-201

Lien, T. F-574 Seljesth M.V. U-620

Lindstols Skips- & Batbyggeri A-l 1A Selo-Gjerstrup F-553

Lorentzen Hydr. og M.V. F-560 Selsbakk Fabrikker U-628

Lovola, Joh. A-9 Selstad, Brdr. A-10

Lowener, Mohn D-325 Semi-Stal D-316

M.M.C. U-611 Setsaas Avd. Rengjoringsteknikk U-634

MSCI U-624 Shiptronics E-405

Maritech A-6 Siemens E-409

Maskin K. Lund F-516 Sigbjorn Iversen A-17

Meijn Machine Fabriek F-520 Sigma Elektroteknisk D-313

Milward Fishing Hooks C-208 Sildemelnaeringens Info, tjeneste B-107

Mjellem & Karlsen F-542 Simonsen & Eek D-315

Mobil Oil Norge U-645 Simonsen Elektro F-509

Moltech Norge E-413 Simrad Subsea E-414

Morenot C-216 Sjofartsdirektoratet B-4A

Mustad & Son, O. F-556 Sjoforsvaret/ Kystvaken B-2

Myhrvold, T. F-561 Skanti Radio E-402

Navimor Spolka A-26 Skipsrevyen B-101

Neraal Maskin E-416 Solhaug, O.S. E-408

Nett & Tau Produkter C-207 Solstrand Slip & Batbyggeri A-17

Newage Norge F-503 Sperry Aerospace Marine Group B-106

Nielsen & Johnsen C-203 Spray Service U-613

Nitedals Taendstikker B-3A Stal Kulde F-558

Noack Norselighet A-24 Stangebye-Hansens C-218

Nogva Motorfarrikk F-562 Steen, Bertel O. F-559

Nordic Supply F-528 Stord Bratz F-554

Nordischer Maschinenbau Rud. Stranda Motorverksted F-510

Baader F-538 Strandeberg, Arne D-318

Nordvestconsult A-4 Straumplast D-317

Norges Fiskarlag A-15 Strom, Leif H. C-213

Norges Fiskeriforskiningsrad B-l Stromberg, Per S. D-316

Norges Fiskerihogskole C-210 Sunnmorsbanken B-l 08

Norges Rafisklag A-27 Syberg Agenturer E-406

Norpack D-303 Som og Presse Teknikk E-541

Norpapp Industri D-314 Soviknes Verft A-17

Norpower, Brodr. Malo U-631 Teknisk Industrieservice F-564

Norsk Marconi U-612 Teknotherm F-512

Norsk Scania-Vabis U-638 Telaeg Aksjeselskap E-404

Norske Fina B-l 13 Tenfjord M.V. F-508

Norske Shell F-566 Tico Norge U-607

Norum Marin U-641 Tronderverftet U-623

Ocean Products D-335 Ulstein Trading F-514

Olsen & Son, Finn Chr. D-324 Univern B-105A

Opplysningsutvalget For Fisk B-l Universal Diesel F-532

Orjavik Industrier F540B Upab; Ulo Produkter F-572

Ostensjo, Johannes A-23 Vaagland Batbyggeri A-17

Owre-Johnsen F-573 Vaagland M.V. U-627

Pay & Brinck U-621 Vakuum-Service D-321

Pettersen Spillfabrikk F-521 Valmet F-571

Polimex S.R.L. B-104 Vega Vekt F-552

Polyform A-13 Vestlandske Fartyrbyggjarlag A-17

Pyrofabrikken F-563 Vestre A-l 1

Q-Marine C-204 Vik & Sandvik F-547

Racal-Norge E-417 Viksund Nor U-617

Ramstad Eskefabrikk D-314 Volvo Norge, Avd. Volvo Penta F-523

Ranheim Papirfabrikk D-332 Wartsila Diesel F-549

Rapp Hydema F-569 Veiberg Gullisken, J. F-543

Rapp Hydema Syd U-646 Wenaas Konfeksjonsfabrikk F-518

Redningsselskapet, NSSR B-3 West Mekan U-636

Refa Fiskeredskap A-5 Wichmann F-535

Rena Kartonfabrik D-319 Wright & McGill A-20

McDermott Shipyard Lays Dredge Keel

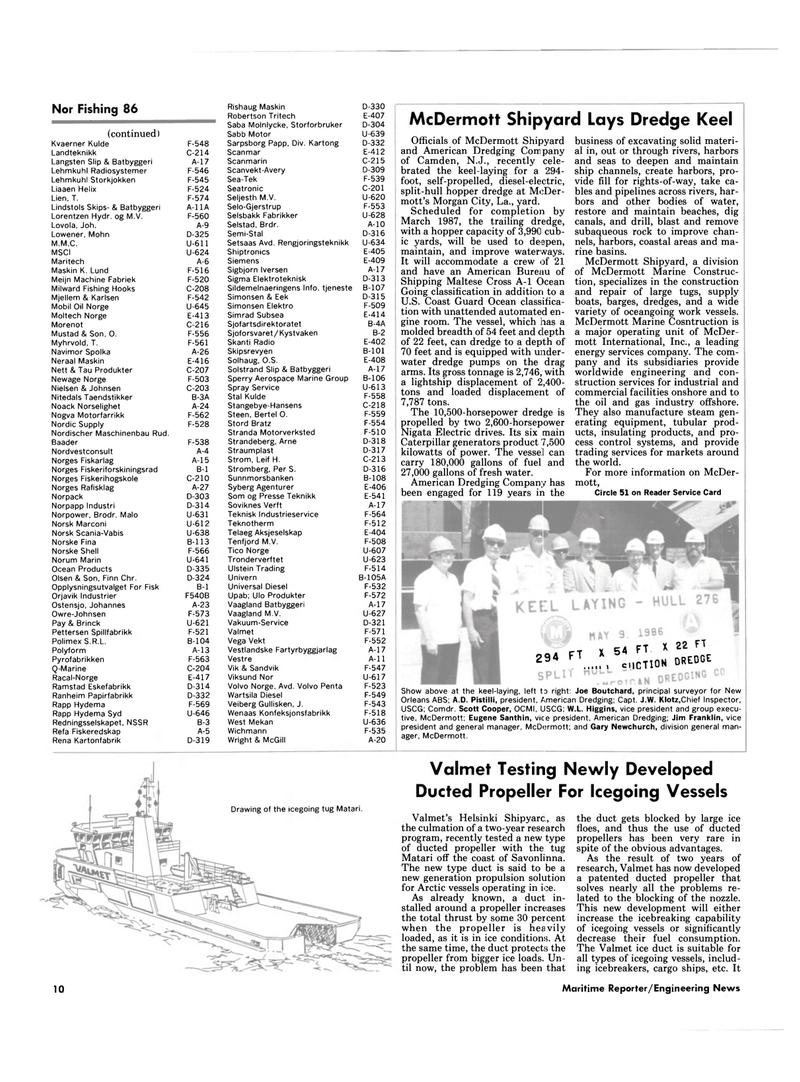

Officials of McDermott Shipyard and American Dredging Company of Camden, N.J., recently cele- brated the keel-laying for a 294- foot, self-propelled, diesel-electric, split-hull hopper dredge at McDer- mott's Morgan City, La., yard.

Scheduled for completion by

March 1987, the trailing dredge, with a hopper capacity of 3,990 cub- ic yards, will be used to deepen, maintain, and improve waterways.

It will accommodate a crew of 21 and have an American Bureau of

Shipping Maltese Cross A-l Ocean

Going classification in addition to a

U.S. Coast Guard Ocean classifica- tion with unattended automated en- gine room. The vessel, which has a molded breadth of 54 feet and depth of 22 feet, can dredge to a depth of 70 feet and is equipped with under- water dredge pumps on the drag arms. Its gross tonnage is 2,746, with a lightship displacement of 2,400- tons and loaded displacement of 7,787 tons.

The 10,500-horsepower dredge is propelled by two 2,600-horsepower

Nigata Electric drives. Its six main

Caterpillar generators product 7,500 kilowatts of power. The vessel can carry 180,000 gallons of fuel and 27,000 gallons of fresh water.

American Dredging Company has been engaged for 119 years in the business of excavating solid materi- al in, out or through rivers, harbors and seas to deepen and maintain ship channels, create harbors, pro- vide fill for rights-of-way, take ca- bles and pipelines across rivers, har- bors and other bodies of water, restore and maintain beaches, dig canals, and drill, blast and remove subaqueous rock to improve chan- nels, harbors, coastal areas and ma- rine basins.

McDermott Shipyard, a division of McDermott Marine Construc- tion, specializes in the construction and repair of large tugs, supply boats, barges, dredges, and a wide variety of oceangoing work vessels.

McDermott Marine Cosntruction is a major operating unit of McDer- mott International, Inc., a leading energy services company. The com- pany and its subsidiaries provide worldwide engineering and con- struction services for industrial and commercial facilities onshore and to the oil and gas industry offshore.

They also manufacture steam gen- erating equipment, tubular prod- ucts, insulating products, and pro- cess control systems, and provide trading services for markets around the world.

For more information on McDer- mott,

Circle 51 on Reader Service Card

Show above at the keel-laying, left tD right: Joe Boutchard, principal surveyor for New

Orleans ABS; A.D. Pistilli, president, American Dredging; Capt. J.W. Klotz,Chief Inspector,

USCG; Comdr. Scott Cooper, OCMI, USCG; W.L. Higgins, vice president and group execu- tive, McDermott; Eugene Santhin, vice president, American Dredging; Jim Franklin, vice president and general manager, McDermott; and Gary Newchurch, division general man- ager, McDermott.

Drawing of the icegoing tug Matari.

Valmet Testing Newly Developed

Ducted Propeller For Icegoing Vessels

Valmet's Helsinki Shipyarc., as the culmation of a two-year research program, recently tested a new type of ducted propeller with the tug

Matari off the coast of Savonlinna.

The new type duct is said to be a new generation propulsion solution for Arctic vessels operating in ice.

As already known, a duct in- stalled around a propeller increases the total thrust by some 30 percent when the propeller is heavily loaded, as it is in ice conditions. At the same time, the duct protects the propeller from bigger ice loads. Un- til now, the problem has been that the duct gets blocked by large ice floes, and thus the use of ducted propellers has been very rare in spite of the obvious advantages.

As the result of two years of research, Valmet has now developed a patented ducted propeller that solves nearly all the problems re- lated to the blocking of the nozzle.

This new development will either increase the icebreaking capability of icegoing vessels or significantly decrease their fuel consumption.

The Valmet ice duct is suitable for all types of icegoing vessels, includ- ing icebreakers, cargo ships, etc. It

CT X 54 FT X 22 H 294 . ciicTION 0REDGE 10 Maritime Reporter/Engineering News

7

7

9

9