Page 29: of Maritime Reporter Magazine (October 1986)

Read this page in Pdf, Flash or Html5 edition of October 1986 Maritime Reporter Magazine

Wrightsville, Pa., offers a variety of machinery to the marine industry.

One of the most popular pieces of equipment is the series CPD or cus- tom power drum. This unit is con- structed of a fabricated steel drum mounted in bearings with various drive styles available. These ma- chines are built to customer require- ments for size and capacity.

The CPD is designed primarily for storage and winching of cables and lines in marine usage.

A special weather-proofing pack- age for shipboard environment is also available. This package in- cludes stainless steel shafting, total- ly enclosed motors and controls, sealed bearings, and galvanized un- dercoating with rubberized paint.

These same corrosion-preventive measures can be applied to any of

Reel-O-Matic's equipment that have applications throughout the marine industry.

Another frequently used piece of equipment is the RS/VS series of shafted stationary coiling and reel- ing machines. These units can be bolted or welded to the deck of a ship to pull any flexible material onto a reel or coil. The RS/VS is offered with various drive configu- rations to suit any particular need.

Reel-O-Matic's H.J/KVS series mobile reeling and coiling machine also is often used aboard ship be- cause it has all of the outstanding features of the RS/VS and, in addi- tion, it is mobile. A configuration of locking wheels and swivel casters allows this machine to be easily moved from job to job.

SALZGITTER/KOCKS

Circle 52 on Reader Service Card

Having established itself as a de- signer and constructor of container cranes for seaports, the Kocks

Crane and Marine Company (KCM) of Pittsburgh, Pa., has concluded an agreement with one of the Salzgitter

Group of companies for supplying all of its bulk materials handling products for the U.S. market. The new venture will be identified as

Salzgitter-Kocks Bulk Systems and will operate as a division of KCM.

Market areas being looked at are seaports, inland terminals, utilities, and general bulk commodities ter- minals including cement and grain industries. The company's diverse product line includes every conceiv- able material handling and storage system . . . pneumatics, belt con- veyors, mining, ship loading/un- loading, indoor storage, and stack- ing and reclaiming.

Other equipment available from

Salzgitter-Kocks includes a com- plete line of bulk handling equip- ment including stackers, stacker- reclaimers, scraper reclaimers, clamshell, pneumatic, continuous ship and barge unloaders, buckets, grabs, and coal blending systems.

The company has expertise in the handling and processing of lignite, coal, potash, cement, alumina, sili- ca, phosphate, and other commodi- ties. Design, supply, and construc- tion is available for equipment and facilities.

October, 1986

SCHOELLHORN-ALBRECHT

Circle 53 on Reader Service Card

The Schoellhorn-Albrecht Divi- sion of St. Louis Ship manufactures the 1824 family of deck capstans that have been in service for more than 40 years. These capstans have fully normalized and stress-relieved cast steel barrels and right-angle worm gear housing. They are driven through a structural-frame- mounted, spur-gear-reduced, right- angled worm gear drive. The worm drive operates in a continuous oil bath, and the bronze bushings have pressurized grease fittings.

Primary power is provided by a 30-hp marine electric motor fitted with a 120-percent torque capacity magnetic disc brake.

The 1824 capstan is designed to provide 10,000 pounds of pull at 55 feet per minute, and 20,000 pounds at 28 fpm. Ultimate pull is 55,000 pounds, with an ultimate static holding capacity of 100,000 pounds.

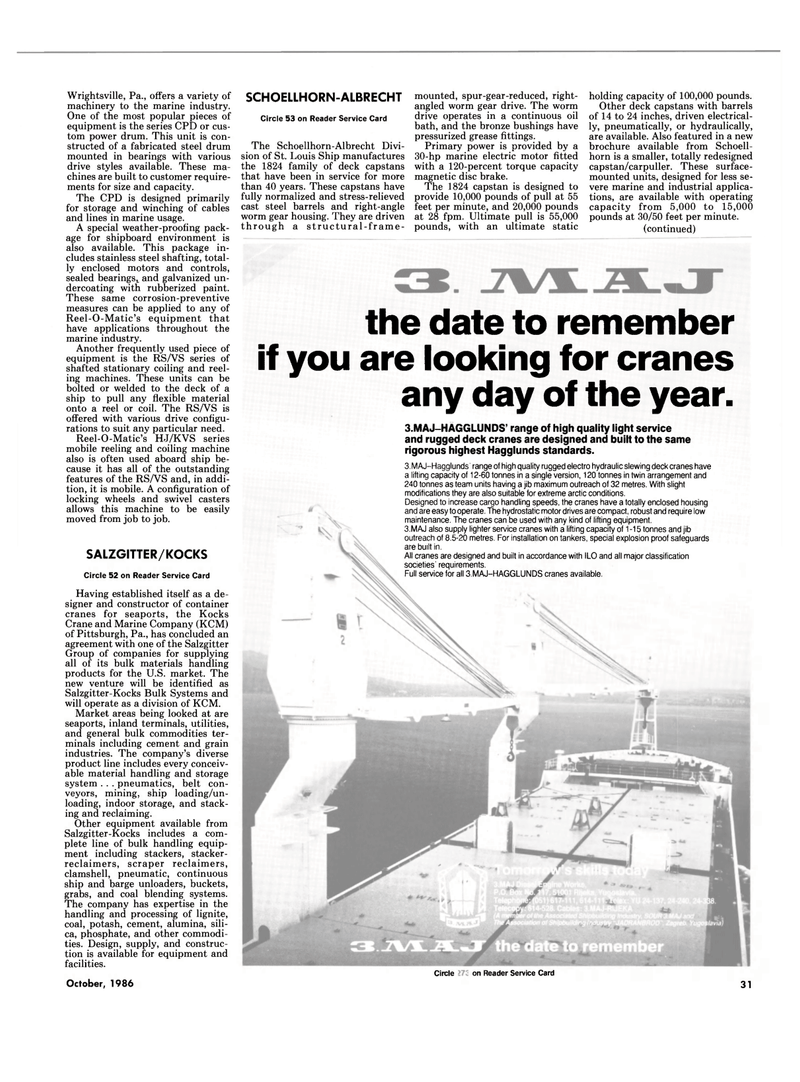

Other deck capstans with barrels of 14 to 24 inches, driven electrical- ly, pneumatically, or hydraulically, are available. Also featured in a new brochure available from Schoell- horn is a smaller, totally redesigned capstan/carpuller. These surface- mounted units, designed for less se- vere marine and industrial applica- tions, are available with operating capacity from 5,000 to 15,000 pounds at 30/50 feet per minute, (continued) the date to remember if you are looking for cranes any day of the year. 3.MAJ-HAGGLUNDS' range of high quality light service and rugged deck cranes are designed and built to the same rigorous highest Hagglunds standards. 3. MAJ-Hagglunds' range of high quality rugged electro hydraulic slewing deck cranes have a lifting capacity of 12-60 tonnes in a single version, 120 tonnes in twin arrangement and 240 tonnes as team units having a jib maximum outreach of 32 metres. With slight modifications they are also suitable for extreme arctic conditions.

Designed to increase cargo handling speeds, the cranes have a totally enclosed housing and are easy to operate. The hydrostatic motor drives are compact, robust and require low maintenance. The cranes can be used with any kind of lifting equipment. 3.MAJ also supply lighter service cranes with a lifting capacity of 1 -15 tonnes and jib outreach of 8.5-20 metres. For installation on tankers, special explosion proof safeguards are built in.

All cranes are designed and built in accordance with ILO and all major classification societies' requirements.

Full service for all 3.MAJ-HAGGLUNDS cranes available.

Circle 119 on Reader Service Card 31

28

28

30

30