Page 22: of Maritime Reporter Magazine (June 1989)

Read this page in Pdf, Flash or Html5 edition of June 1989 Maritime Reporter Magazine

U.S. NAVY

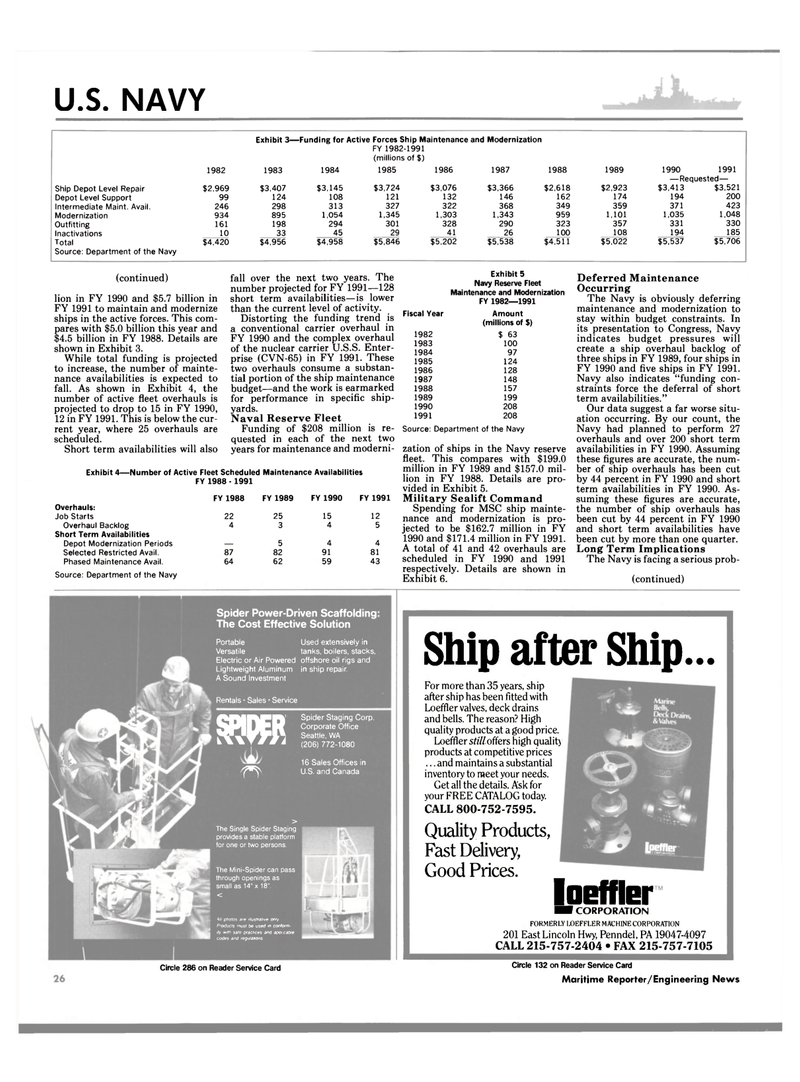

Exhibit 3—Funding for Active Forces Ship Maintenance and Modernization

FY 1982-1991 (millions of $) 1982 1983 1984 1985 1986 1987 1988 1989 1990 1991 —Requested—

Ship Depot Level Repair $2,969 $3,407 $3,145 $3,724 $3,076 $3,366 $2,618 $2,923 $3,413 $3,521

Depot Level Support 99 124 108 121 132 146 162 174 194 200

Intermediate Maint. Avail. 246 298 313 327 322 368 349 359 371 423

Modernization 934 895 1,054 1,345 1,303 1,343 959 1,101 1,035 1,048

Outfitting 161 198 294 301 328 290 323 357 331 330

Inactivations 10 33 45 29 41 26 100 108 194 185

Total $4,420 $4,956 $4,958 $5,846 $5,202 $5,538 $4,511 $5,022 $5,537 $5,706

Source: Department of the Navy (continued) lion in FY 1990 and $5.7 billion in

FY 1991 to maintain and modernize ships in the active forces. This com- pares with $5.0 billion this year and $4.5 billion in FY 1988. Details are shown in Exhibit 3.

While total funding is projected to increase, the number of mainte- nance availabilities is expected to fall. As shown in Exhibit 4, the number of active fleet overhauls is projected to drop to 15 in FY 1990, 12 in FY 1991. This is below the cur- rent year, where 25 overhauls are scheduled.

Short term availabilities will also fall over the next two years. The number projected for FY 1991—128 short term availabilities—is lower than the current level of activity.

Distorting the funding trend is a conventional carrier overhaul in

FY 1990 and the complex overhaul of the nuclear carrier U.S.S. Enter- prise (CVN-65) in FY 1991. These two overhauls consume a substan- tial portion of the ship maintenance budget—and the work is earmarked for performance in specific ship- yards.

Naval Reserve Fleet

Funding of $208 million is re- quested in each of the next two years for maintenance and moderni-

Exhibit 4—Number of Active Fleet Scheduled Maintenance Availabilities

FY 1988 - 1991

FY 1988 FY 1989 FY 1990 FY 1991

Overhauls:

Job Starts 22 25 15 12

Overhaul Backlog 4 3 4 5

Short Term Availabilities

Depot Modernization Periods — 5 4 4

Selected Restricted Avail. 87 82 91 81

Phased Maintenance Avail. 64 62 59 43

Exhibit 5

Navy Reserve Fleet

Maintenance and Modernization

FY 1982—1991

Fiscal Year Amount (millions of $) 1982 $ 63 1983 100 1984 97 1985 124 1986 128 1987 148 1988 157 1989 199 1990 208 1991 208

Source: Department of the Navy

Source: Department of the Navy zation of ships in the Navy reserve fleet. This compares with $199.0 million in FY 1989 and $157.0 mil- lion in FY 1988. Details are pro- vided in Exhibit 5.

Military Sealift Command

Spending for MSC ship mainte- nance and modernization is pro- jected to be $162.7 million in FY 1990 and $171.4 million in FY 1991.

A total of 41 and 42 overhauls are scheduled in FY 1990 and 1991 respectively. Details are shown in

Exhibit 6.

Deferred Maintenance

Occurring

The Navy is obviously deferring maintenance and modernization to stay within budget constraints. In its presentation to Congress, Navy indicates budget pressures will create a ship overhaul backlog of three ships in FY 1989, four ships in

FY 1990 and five ships in FY 1991.

Navy also indicates "funding con- straints force the deferral of short term availabilities."

Our data suggest a far worse situ- ation occurring. By our count, the

Navy had planned to perform 27 overhauls and over 200 short term availabilities in FY 1990. Assuming these figures are accurate, the num- ber of ship overhauls has been cut by 44 percent in FY 1990 and short term availabilities in FY 1990. As- suming these figures are accurate, the number of ship overhauls has been cut by 44 percent in FY 1990 and short term availabilities have been cut by more than one quarter.

Long Term Implications

The Navy is facing a serious prob- (continued)

Spider Power-Driven Scaffolding

The Cost Effective Solution

Portable Used extensively in

Versatile tanks, boilers, stacks,

Electric or Air Powered offshore oil rigs and

Lightweight Aluminum in ship repair.

A Sound Investment

Rentals • Sales • Service sm. o >

The Single Spider Staging provides a stable platform for one or two persons.

The Mini-Spider can pass through openings as small as 14" x 18". <

All photos are illustrative only

Products must be used m conform- ity with sale practices and apoi.cattle codes and regulations

Spider Staging Corp.

Corporate Office

Seattle, WA (206) 772-1080 16 Sales Offices in

U.S. and Canada

Circle 286 on Reader Service Card Circle 132 on Reader Service Card

Maritime Reporter/Engineering News

Ship after Ship...

For more than 35 years, ship after ship has been fitted with

Loeffler valves, deck drains and bells. The reason? High quality products at a good price.

Loeffler still offers high quality products at competitive prices ... and maintains a substantial inventory to meet your needs.

Get all the details. Ask for your FREE CATALOG today.

CALL 800-752-7595.

Quality Products,

Fast Delivery,

Good Prices. loeffler

WK CORPORATION

FORMERLY I.OEFFLER MACHINE CORPORATION 201 East Lincoln Hwy, Penndel, PA 19047-4097

CALL 215-757-2404 • FAX 215-757-7105

21

21

23

23