Page 23: of Maritime Reporter Magazine (February 1995)

Read this page in Pdf, Flash or Html5 edition of February 1995 Maritime Reporter Magazine

EUROPEAN UPDATE (Continued from page 23) priorities could be established at the outset. A PERT program was used as a planning tool, developing the necessary software to provide the interfaces for the different databases used in the budgeting, purchasing, engineering and production depart- ments with automatic update and feedback provision.

According to Mr. Horrillo and

Mr. Arce, the CAD-CAM system is a fundamental element in the build- ing strategy. Among its main ad- vantages are accurate dimensional information, cutting, shaping, mark- ing and positioning detail, piping and wiring information and estab- lishing work packages within the integrated construction philosophy.

New machinery considered im- perative for the company's San

Fernando yard located near Cadiz on Spain's southwest coast (Bazan has two other yards) included an underwater plasma cutting machine with two pools capable of handling a pair of plates 32 ft. x 6.5 ft. (9.75 m x 2 m) each and a seam welder with the ability to weld plates 32 ft. long into panels 32 ft. square. Informa- tion from the CAD system is trans- mitted directly to the new cutting machine through a fiber optic cable.

To improve the layout and make best use of existing facilities, the covered working area has also been increased by building two new shops with a total surface area of over 6,000 sq. m., one of which has twin traveling cranes with a total lifting capacity of 100 tons.

Production begins with the re- ception and storage of plates and profiles in one of the new shops, from where they pass to the adja- cent fabrication building for cutting and shaping. Once the elements which form a block have been pre- pared, work proceeds in the assem- bly shop until ready for fitting into the appropriate section in the sec- ond of the newbuildings. Finally the sections are moved to the build- ing berths where they are joined together. Here outfitting continues until launching.

Both hull and superstructure of the Mestral are in welded alumi- num, with the bottom sides and decks longitudinally stiffened and specially reinforced chines. The bridge deck is rigidly connected to the hull girder so that the stiffness of the vessel is high and stresses kept within allowable fatigue val- ues without weight compromise.

The area beneath the car deck is divided by seven watertight bulk- heads into five void spaces, two en- gine spaces and one waterjet room.

Four Caterpillar 3616 diesels each developing 5,400 kW drive KaMeWa waterjets through Voith reduction gearboxes.

The first two Mestrals were origi- nally ordered by local operator

Trasmediterranea and designed for service on the Barcelona-Mallorca/

Ibiza route carrying up to 450 pas- sengers and 76 cars a distance of over 100 nautical miles at 35 knots.

Vessel number one was launched in

July 1994, but in October—without having gone into service — was sim- ply repainted in the livery of Sea

Shuttle, a New Zealand subsidiary of Buquebus, an operator based in

Uruguay who now owns the vessel.

Trasmediterranea has agreed to transfer its order to Mestrals 2 and 3, taking delivery of the first in May 1995, in time for the busy summer season. Meanwhile, Buquebus has ordered a larger version, although little detail is known except that it will be able to carry 1,250 passen- gers and 250 cars at 40 knots and use six conventional diesel engines, almost certainly from Caterpillar, as the two companies are involved in a joint venture to produce a lighter more powerful version of the 3616.

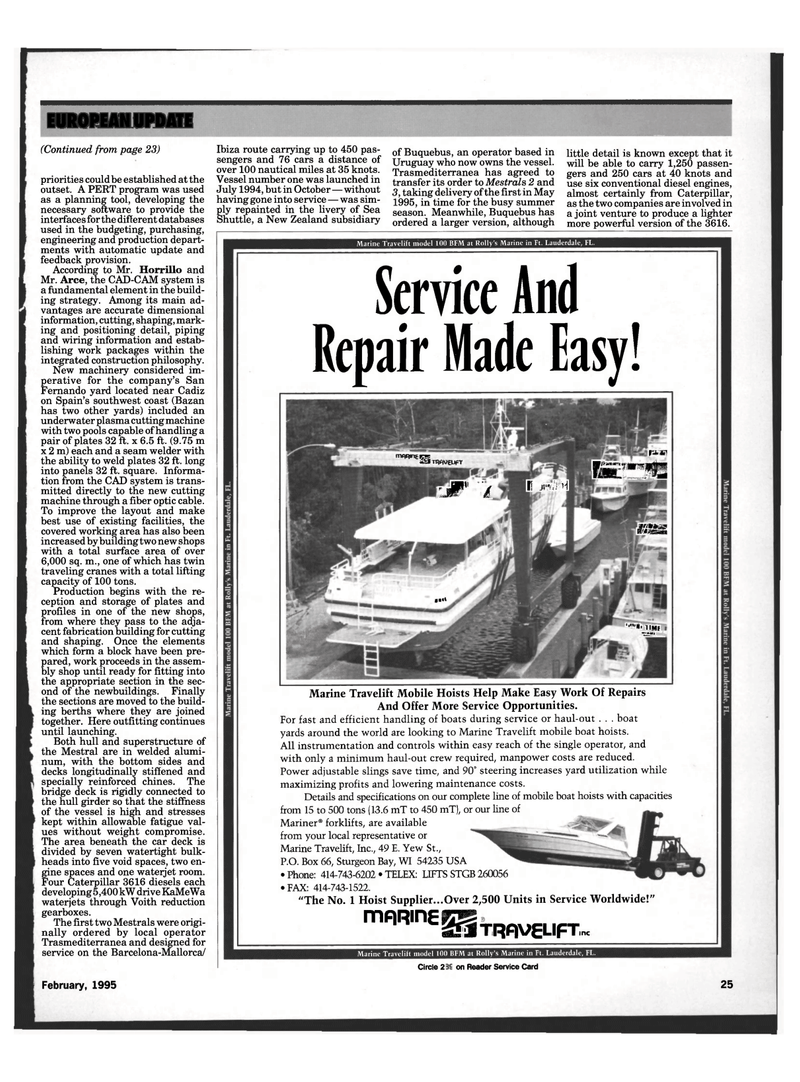

Marine Travelift model 100 BFM at Rolly's Marine in Ft. Lauderdale, FL.

Service And Repair Made Easy! irxwmgijas

SStiwobjpt r»«i

IjP1 £ I ji i H

K~nnatm ML • 3U m»*m mmim «t«« '•"'•"' IIMf — m

Marine Travelift Mobile Hoists Help Make Easy Work Of Repairs

And Offer More Service Opportunities.

For fast and efficient handling of boats during service or haul-out . . . boat yards around the world are looking to Marine Travelift mobile boat hoists.

All instrumentation and controls within easy reach of the single operator, and with only a minimum haul-out crew required, manpower costs are reduced.

Power adjustable slings save time, and 90° steering increases yard utilization while maximizing profits and lowering maintenance costs.

Details and specifications on our complete line of mobile boat hoists with capacities from 15 to 500 tons (13.6 mT to 450 mT), or our line of

Mariner® forklifts, are available from your local representative or

Marine Travelift, Inc., 49 E. Yew St.,

P.O. Box 66, Sturgeon Bay, WI 54235 USA • Phone: 414-743-6202 • TELEX: LIFTS STGB 260056 •FAX: 414-743-1522. "The No. 1 Hoist Supplier...Over 2,500 Units in Service Worldwide!" mflRinE gg!| TRPIVELIFT.nc

Marine Travelift model 100 BFM at Rolly's Marine in Ft. Lauderdale, FL.

Circle 273 on Reader Service Card

February, 1995 25

22

22

24

24