Page 30: of Maritime Reporter Magazine (February 1995)

Read this page in Pdf, Flash or Html5 edition of February 1995 Maritime Reporter Magazine

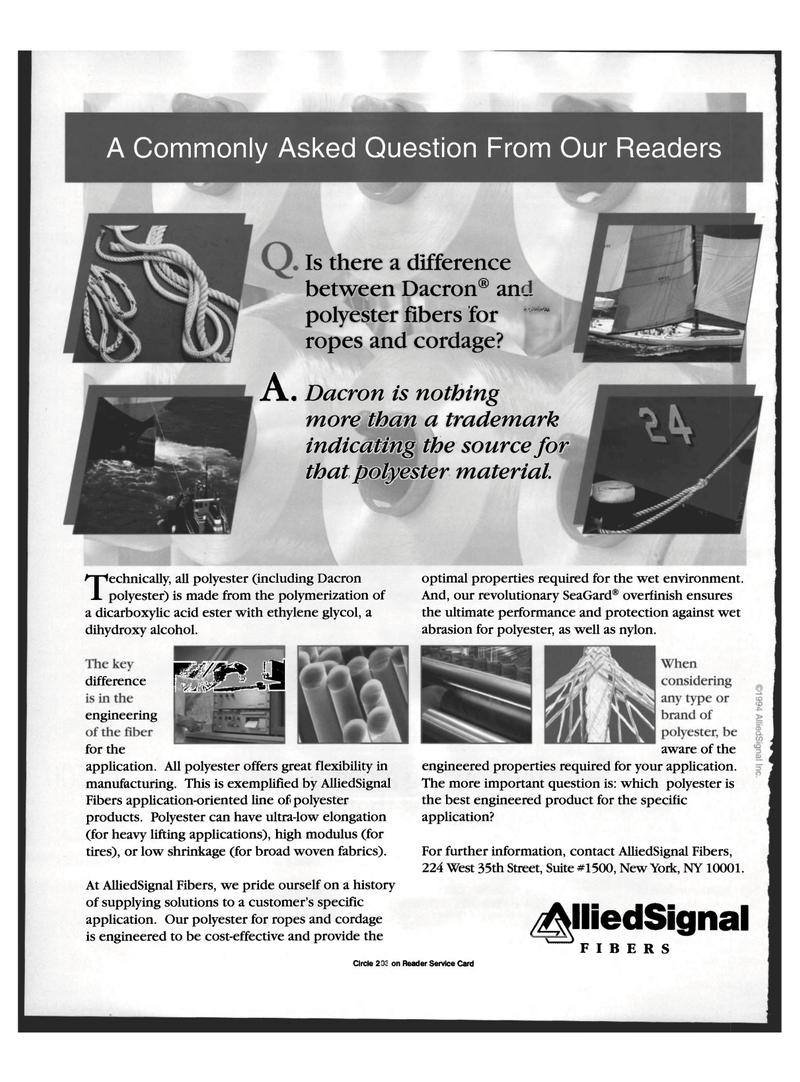

A Commonly Asked Question From Our Readers difference ^^ J^S engineering for the application. All polyester offers great flexibility in manufacturing. This is exemplified by AlliedSignal

Fibers application-oriented line of polyester products. Polyester can have ultra-low elongation (for heavy lifting applications), high modulus (for tires), or low shrinkage (for broad woven fabrics).

At AlliedSignal Fibers, we pride ourself on a history of supplying solutions to a customer's specific application. Our polyester for ropes and cordage is engineered to be cost-effective and provide the aware of the engineered properties required for your application.

The more important question is: which polyester is the best engineered product for the specific application?

For further information, contact AlliedSignal Fibers, 224 West 35th Street, Suite #1500, New York, NY 10001. ^IliedSignal

FIBERS

Circle 259 on Reader Service Card

A. Dacron is nothing more than a trademark indicating the source for that polyester material.

Technically, all polyester (including Dacron polyester) is made from the polymerization of a dicarboxylic acid ester with ethylene glycol, a dihydroxy alcohol. optimal properties required for the wet environment.

And, our revolutionary SeaGard® overfinish ensures the ultimate performance and protection against wet abrasion for polyester, as well as nylon.

Is there a difference between Dacron® an„ polyester fibers for ropes and cordage? | xiSfeiS

29

29

31

31