Page 40: of Maritime Reporter Magazine (December 1996)

Read this page in Pdf, Flash or Html5 edition of December 1996 Maritime Reporter Magazine

w

Keeping A Step Ahead

Japan maintains its commercial shipbuilding edge using experience, technology

By Greg Trauthwein, editorial director

Numbers don't lie.

The Japanese shipbuilding industry is having another solid year, as evidenced by the most recent statistics released from the

Japan Ship Centre. From the time period between April and

September 1996, new orders totaled nearly 5.8 million gt, a 24.5 percent increase over the same period the last year.

Despite fierce international competition, escalating labor costs and currency concerns, the Japanese maritime industry is main- taining its edge as the top builder of commercial ships in the world.

The following pages highlight many of the companies which have made, and intend to keep, Japan near the top of the com- mercial shipbuilding heap for some time to come. This section also houses the Great Ships of '96 from Japan.

Ship Machinery Production Up

According to the Japanese Marine Equipment

Association (JSMEA), ship machinery and equip- ment manufactured in Japan in 1995 totaled ¥819 billion, up ¥7.1 billion from 1994.

Marine internal combustion engines alone accounted for 31.5 percent of that total (¥257.8 billion). (See chart to the right).

In looking at the number of internal combustion engines produced, large diesel engines (over 10,000 PS in per- unit power output) registered a 6.2 percent decline, while medium-sized diesel engines (1,000 to 10,000 PS out- put) registered a 5.6 percent decline.

The production of small diesel engines (lower than 1,000 PS) also slightly decreased, while the production of out- vious year. The annual total of exports, which held a 17.4 percent share of overall output, registered a decline for the fifth straight year.

In looking at all of the products exported, only three categories constituted 85 percent of the total: marine internal combustion engines (¥71.9 billion, 50.4 percent of total export value); parts and accessories (¥27.3 billion, 19.1 percent); and nautical equip- ment (¥22.6 billion, 15.8 percent).

By destination, Asia accounted for 39.3 percent of purchases of equipment from Japan (¥56.1 billion), followed by North America (¥37.1 billion, 26 percent), and Europe (¥35.1 billion, 24.6 per- cent). Notably, these three regions alone held a combined share of 90 percent in the total value of ship machinery and equipment exported from Japan. Other significant buyers of Japanese equipment included: South America (¥5.1 billion); Oceania (¥4 billion); Africa (¥2.8 billion); and the Middle East (¥2.3 billion).

Ship

Machinery

Production in 1995

Equipment Value (Mil ¥) Share (%) • Marine internal combustion engines 257,817 31.5 • Parts and accessories 188,523 23

Outfitting 114,541 14 1 Marine auxiliary machinery 79,587 9.7 • Nautical equipment 65,467 8 board motors increased 11.7 percent. On the export front, a total of ¥142.8 billion

Japanese equipment was manufactured for use outside of Japan, roughly the same amount of the pre

The Shipbuilders

Any conversation about Japanese shipbuilding starts with Mitsubishi Heavy Industries (MHI), the largest shipbuilder in the country. According to

MHI's annual report, total ship sales for 1995 totaled nearly $2.6 billion, while ship repair and conversion activity accounted for $395 million. These numbers were not significantly more than the previous year. However, the company did suffer a higher than 25 percent slump in the steel structures and products category, a drop which resulted in a decline of 9.1 percent for the Shipbuilding and

Steel Structures Group as a whole.

During the year, MHI has won a num- ber of impressive orders, including orders for a series of ten 4,173-TEU boxships from

Taiwan's Evergreen Corp., two 4,369-TEU ships from Singapore's Neptune Orient Lines (NOL), and two 4,900-TEU vessels from Orient

Overseas Lines (OOCL). 42

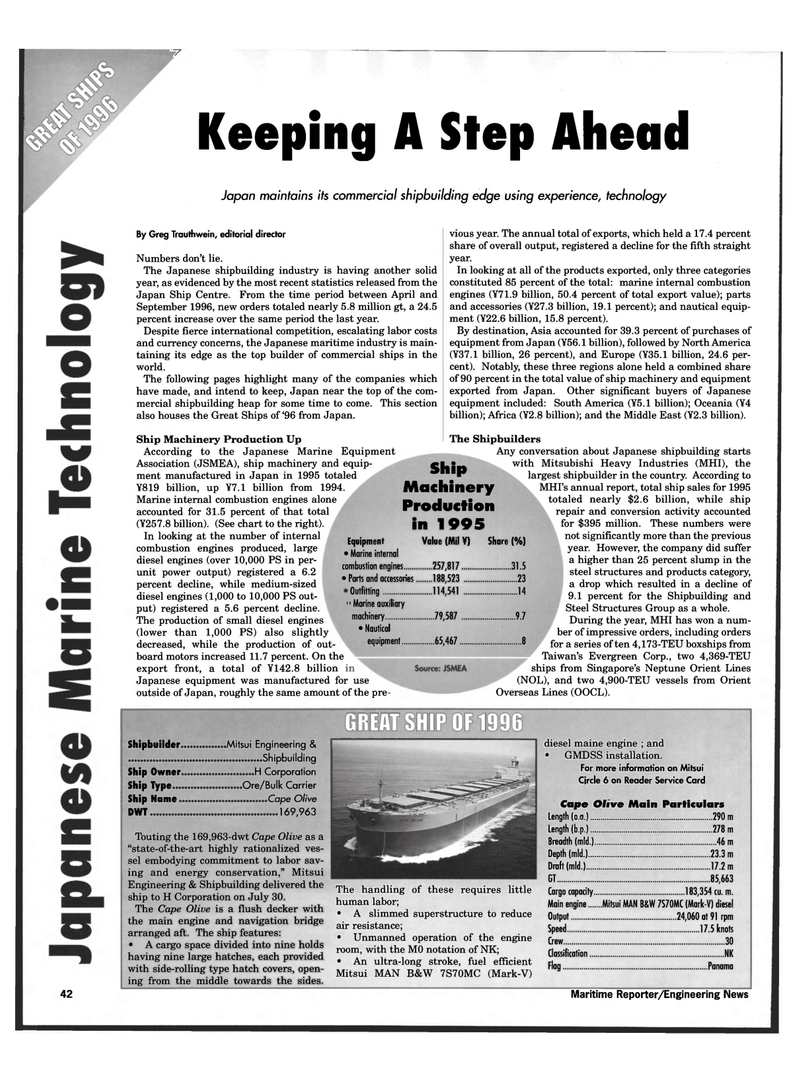

Shipbuilder Mitsui Engineering &

Shipbuilding

Ship Owner H Corporation

Ship Type Ore/Bulk Carrier

Ship Name Cape Olive

DWT 169,963

Touting the 169,963-dwt Cape Olive as a "state-of-the-art highly rationalized ves- sel embodying commitment to labor sav- ing and energy conservation," Mitsui

Engineering & Shipbuilding delivered the ship to H Corporation on July 30.

The Cape Olive is a flush decker with the main engine and navigation bridge arranged aft. The ship features: • A cargo space divided into nine holds having nine large hatches, each provided with side-rolling type hatch covers, open- ing from the middle towards the sides.

The handling of these requires little human labor; • A slimmed superstructure to reduce air resistance; • Unmanned operation of the engine room, with the M0 notation of NK; • An ultra-long stroke, fuel efficient

Mitsui MAN B&W 7S70MC (Mark-V) diesel maine engine ; and • GMDSS installation.

For more information on Mitsui

Circle 6 on Reader Service Card

Cape Olive Main Particulars length (o.a.) 290 m length (b.p.) 278 m

Breadth (mid.) 46 m

Depth (mid.) 23.3 m

Draft (mid.) 17.2 m

GT 85,663

Cargo capacity 183,354 cu. m.

Main engine Mitsui MAN B&W 7S70MC (Mark-V) diesel

Output 24,060 at 91 rpm

Speed 17.5 knots

Crew 30

Classification NK

Flag Panama

Maritime Reporter/Engineering News

39

39

41

41