Page 58: of Maritime Reporter Magazine (February 1998)

Read this page in Pdf, Flash or Html5 edition of February 1998 Maritime Reporter Magazine

Protecting The

Investment

New I ACS and IMO rules are designed to ensure the long life and safety of ship and crew, which should be of high interest given the tremendous amount of investment in new tonnage. The following data from Drewry's "Dry Bulk

Carrier Prospects, 1997-2000:

Meeting The Challenge of

Oversupply," highlights some of these costs.

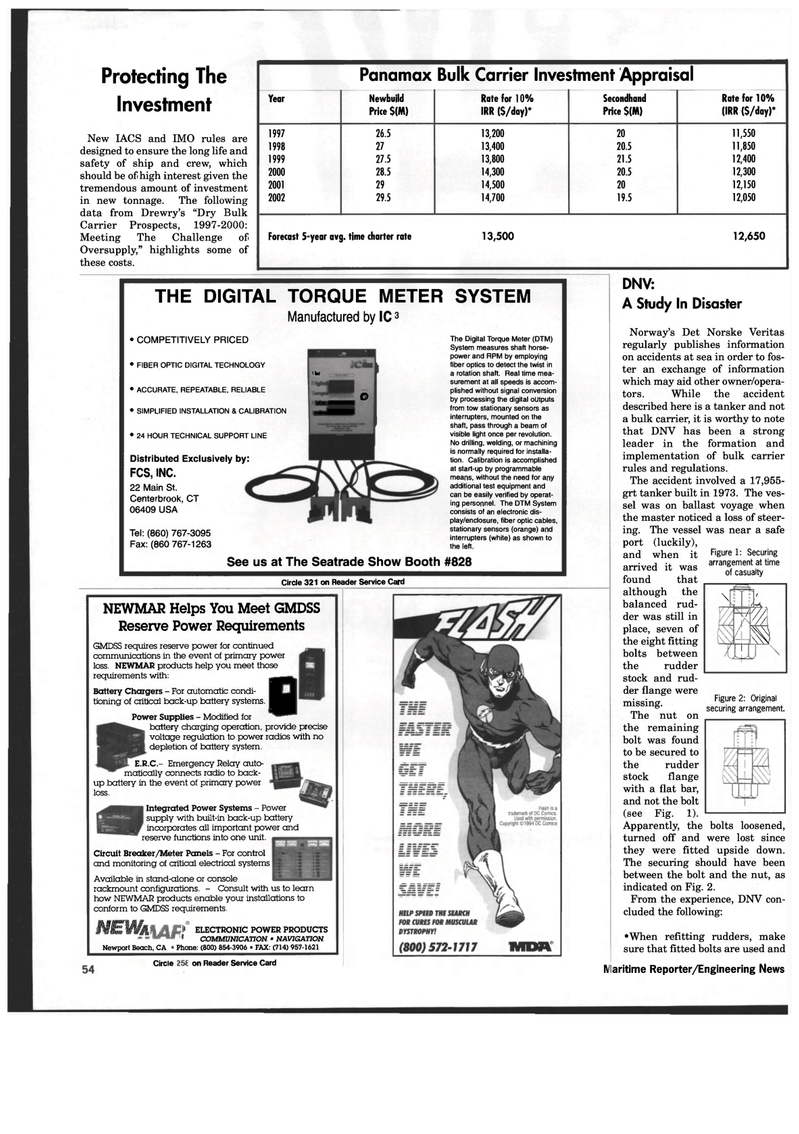

Panamax Bulk Carrier Investment Appraisal

Year Newbuild Rate for 10% Secondhand Rate for 10%

Price $(M) IRR ($/day)* Price $(M) (IRR {$/day)* 1997 26.5 13,200 20 11,550 1998 27 13,400 20.5 11,850 1999 27.5 13,800 21.5 12,400 2000 28.5 14,300 20.5 12,300 2001 29 14,500 20 12,150 2002 29.5 14,700 19.5 12,050

Forecast 5-year avg. time charter rate 13,500 12,650

THE DIGITAL TORQUE METER SYSTEM

Manufactured by IC3 • COMPETITIVELY PRICED • FIBER OPTIC DIGITAL TECHNOLOGY • ACCURATE, REPEATABLE, RELIABLE • SIMPLIFIED INSTALLATION & CALIBRATION • 24 HOUR TECHNICAL SUPPORT LINE

Distributed Exclusively by:

FCS, INC. 22 Main St.

Centerbrook, CT 06409 USA , © derMH ysttaMRRP

Tel: (860) 767-3095

Fax: (860 767-1263

The Digital Torque Meter (DTM)

System measures shaft horse- power and RPM by employing fiber optics to detect the twist in a rotation shaft. Real time mea- surement at all speeds is accom- plished without signal conversion by processing the digital outputs from tow stationary sensors as interrupters, mounted on the shaft, pass through a beam of visible light once per revolution.

No drilling, welding, or machining is normally required for installa- tion. Calibration is accomplished at start-up by programmable means, without the need for any additional test equipment and can be easily verified by operat- ing personnel. The DTM System consists of an electronic dis- play/enclosure, fiber optic cables, stationary sensors (orange) and interrupters (white) as shown to the left.

See us at The Seatrade Show Booth #828

Circle 321 on Reader Service Card

NEWMAR Helps You Meet GMDSS

Reserve Power Requirements

GMDSS requires reserve power for continued communications in the event of primary power loss. NEWMAR products help you meet those requirements with:

Battery Chargers - For automatic condi- tioning of critical back-up battery systems. B

Power Supplies - Modified for battery charging operation, provide precise voltage regulation to power radios with no depletion of battery system.

E.R.C.- Emergency Relay auto- matically connects radio to back- up battery in the event of primary power loss.

Integrated Power Systems - Power supply with built-in back-up battery incorporates all important power and reserve functions into one unit.

Circuit Breaker/Meter Panels - For control and monitoring of critical electrical systems

Available in stand-alone or console rackmount configurations. - Consult with us to learn how NEWMAR products enable your installations to conform to GMDSS requirements.

NEWA

Newport Beach, CA

III ELECTRONIC POWER PRODUCTS ' COMMUNICATION • NAVIGATION

Phone: (800) 854-3906 • FAX: (714) 957-1621 40-B Circle 337 on Reader Service Card M

DNV:

A Study In Disaster

Norway's Det Norske Veritas regularly publishes information on accidents at sea in order to fos- ter an exchange of information which may aid other owner/opera- tors. While the accident described here is a tanker and not a bulk carrier, it is worthy to note that DNV has been a strong leader in the formation and implementation of bulk carrier rules and regulations.

The accident involved a 17,955- grt tanker built in 1973. The ves- sel was on ballast voyage when the master noticed a loss of steer- ing. The vessel was near a safe port (luckily),

Figure 1: Securing arrangement at time of casualty \ / / 1 1

Figure 2: Original securing arrangement. and when it arrived it was found that although the balanced rud- der was still in place, seven of the eight fitting bolts between the rudder stock and rud- der flange were missing.

The nut on the remaining bolt was found to be secured to the rudder stock flange with a flat bar, and not the bolt (see Fig. 1).

Apparently, the bolts loosened, turned off and were lost since they were fitted upside down.

The securing should have been between the bolt and the nut, as indicated on Fig. 2.

From the experience, DNV con- cluded the following: •When refitting rudders, make sure that fitted bolts are used and aritime Reporter/Engineering News

57

57

59

59