Page 8: of Maritime Reporter Magazine (March 1998)

Read this page in Pdf, Flash or Html5 edition of March 1998 Maritime Reporter Magazine

INVESTMENT IN DESIGN

Uncovered: Lax Coating Application,

Maintenance Come At A High Cost mi J!

Wjf /1 by David Tinsley, technical editor

One Step At A Time

With the increasing complexity of marine coatings, susceptibility to misuse has risen. Although modern systems demand greater vigilance in ensuring correct application and maintenance, problems subse- quently encountered in service point to a lack of specific knowl- edge among shipyards, operators and crews.

Strict protocols now need to be observed in applying coatings, and every step of the process has to be recorded. "It's a precise and time- consuming task, but such are today's commercial pressures that yards and shipowners sometimes feel the need to cut corners," said paints and coatings expert Ed

Jansen, of Antwerp-based Touw-

Jansen.

Any shortcomings in the quality of the preparation and application work, or any cutback on the origi- nal specification in order to speed newbuilding delivery or trim costs, will produce extra cost in the longer term. The coating will dete- riorate quickly and start to blister, flake, crack or crocodile, requiring an expensive repaint.

Tank coatings are particularly sensitive to irregularities, and call for the highest standard of applica- tion. However, according to Mr.

Jansen, most problems with such coatings occur after a vessel has been delivered, due to carelessness or improper use. The slightest chip in a coating can lead to its eventu- al demise, and it is significant that deterioration frequently starts at a spot just below access points through which tools and equip- ment are fed down into the tank in the course of maintenance work.

Non-adherence to the prescribed cargo range within the scope of the protection system can, and does, lead to major problems, particular- ly where the coating resistance list has not been passed on to ship- managers and charterers.

Owners should also impress upon crews the importance of ventila- tion, suggested Mr. Jansen. "In a case not long ago, a complete fleet of chemical carriers had to be re- coated when the crew failed to ven- tilate the cargo tanks properly after carrying methanol," he said. "Water-based cargoes were loaded too soon afterward and the resid- ual methanol in the tank coatings drew water into the coatings, caus- ing swelling and cracking. The whole fleet was out of service for several weeks and the total bill for re-coatings and off-hires topped an estimated $25 million."

As an authority on the subject,

Mr. Jansen takes the view that owners should spend as much time deciding on a paint system as on major machinery or equipment selection. And once a ship has entered service, every effort should be made to ensure that those oper- ating the vessel understand the delicate nature of the tank coatings in particular. (For the latest marine paints and coatings system offerings from manufacturers, please refer to this month's "Marine Coatings &

Corrosion Control" section, which starts on page 58).

The New Thoroughbreds

Medium-speed propulsion ma- chinery of a new, thoroughbred type is set to make its debut in a new generation of North Sea RoRo ships intended to ensure faster, more efficient freight exchange between Sweden, the U.K. and

Belgium.

In addition to the commercial sig- nificance conferred by an opening reference for the 500-mm bore, four-stroke design conceived in

Winterthur, the fountainhead of

Swiss diesel engineering, the pro- ject has a wider industrial aspect in the context of the rationalization taking place in the business in

Europe.

The compact ZA50S perpetuates the Sulzer marque in the medium- speed domain against a backcloth of the commanding presence of the companion Wartsila range in the four-stroke field. The emergence of the new Sulzer machine is of added note for the unmatched level of medium-speed product develop- ment steered from Finland by par- ent organization Wartsila NSD

Corporation, to strengthen the market standing of the Wartsila- branded portfolio.

Work on the ZA50S, though, was set in train well before the combi- nation of Wartsila Diesel with

Fincantieri-owned New Sulzer

Diesel, as an evolutionary progres- sion of the ZA series, which has achieved considerable success in the ZA40S. The fact that the first three recipients of the ZA50S design — the trio of twin-screw, 8,700-dwt Tor Line newbuildings — were ordered from Fincantieri, brought manufacture of the engines within the Italian group's remit.

In any event, the industrial phi- losophy espoused by Wartsila

NSD's Finnish owners is reflected in the company's decision to con- centrate all ZA production at the

Grandi Motori Trieste (GMT) works, in which the Finnish group has a 40 percent stake. The 8

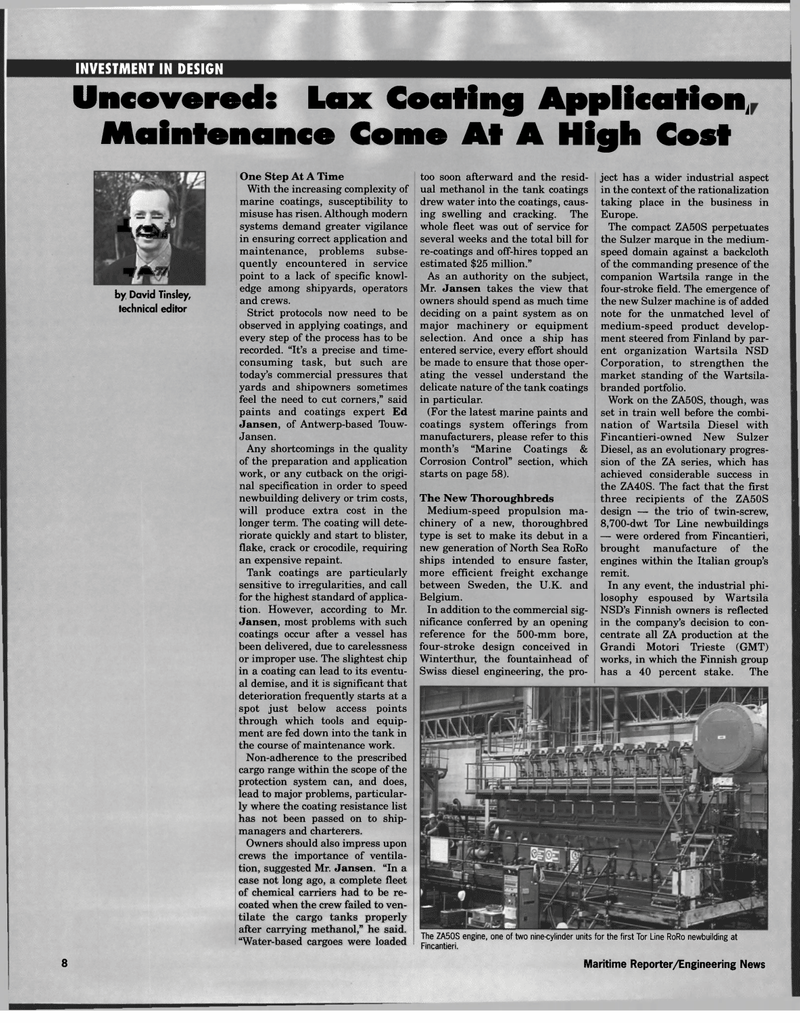

The ZA50S engine, one of two nine-cylinder units for the first Tor Line RoRo newbuilding at

Fincantieri.

Maritime Reporter/Engineering News

7

7

9

9