Page 75: of Maritime Reporter Magazine (April 1998)

Read this page in Pdf, Flash or Html5 edition of April 1998 Maritime Reporter Magazine

SHIP & BOATBUILDING TECHNOLOGY

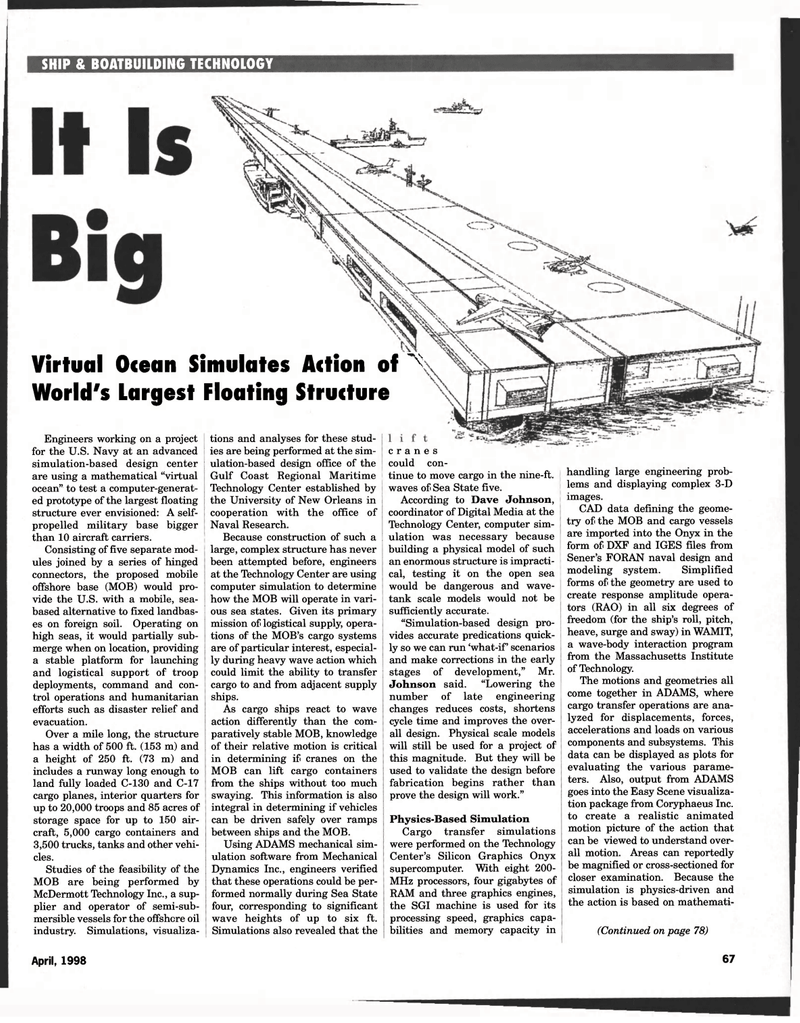

Engineers working on a project for the U.S. Navy at an advanced simulation-based design center are using a mathematical "virtual ocean" to test a computer-generat- ed prototype of the largest floating structure ever envisioned: A self- propelled military base bigger than 10 aircraft carriers.

Consisting of five separate mod- ules joined by a series of hinged connectors, the proposed mobile offshore base (MOB) would pro- vide the U.S. with a mobile, sea- based alternative to fixed landbas- es on foreign soil. Operating on high seas, it would partially sub- merge when on location, providing a stable platform for launching and logistical support of troop deployments, command and con- trol operations and humanitarian efforts such as disaster relief and evacuation.

Over a mile long, the structure has a width of 500 ft. (153 m) and a height of 250 ft. (73 m) and includes a runway long enough to land fully loaded C-130 and C-17 cargo planes, interior quarters for up to 20,000 troops and 85 acres of storage space for up to 150 air- craft, 5,000 cargo containers and 3,500 trucks, tanks and other vehi- cles.

Studies of the feasibility of the

MOB are being performed by

McDermott Technology Inc., a sup- plier and operator of semi-sub- mersible vessels for the offshore oil industry. Simulations, visualiza-

Virtual Ocean Simulates Action of ^

World's Largest Floating Structure tions and analyses for these stud- ies are being performed at the sim- ulation-based design office of the

Gulf Coast Regional Maritime

Technology Center established by the University of New Orleans in cooperation with the office of

Naval Research.

Because construction of such a large, complex structure has never been attempted before, engineers at the Technology Center are using computer simulation to determine how the MOB will operate in vari- ous sea states. Given its primary mission of logistical supply, opera- tions of the MOB's cargo systems are of particular interest, especial- ly during heavy wave action which could limit the ability to transfer cargo to and from adjacent supply ships.

As cargo ships react to wave action differently than the com- paratively stable MOB, knowledge of their relative motion is critical in determining if cranes on the

MOB can lift cargo containers from the ships without too much swaying. This information is also integral in determining if vehicles can be driven safely over ramps between ships and the MOB.

Using ADAMS mechanical sim- ulation software from Mechanical

Dynamics Inc., engineers verified that these operations could be per- formed normally during Sea State four, corresponding to significant wave heights of up to six ft.

Simulations also revealed that the cranes could con- tinue to move cargo in the nine-ft. waves of Sea State five.

According to Dave Johnson, coordinator of Digital Media at the

Technology Center, computer sim- ulation was necessary because building a physical model of such an enormous structure is impracti- cal, testing it on the open sea would be dangerous and wave- tank scale models would not be sufficiently accurate. "Simulation-based design pro- vides accurate predications quick- ly so we can run 'what-if' scenarios and make corrections in the early stages of development," Mr.

Johnson said. "Lowering the number of late engineering changes reduces costs, shortens cycle time and improves the over- all design. Physical scale models will still be used for a project of this magnitude. But they will be used to validate the design before fabrication begins rather than prove the design will work."

Physics-Based Simulation

Cargo transfer simulations were performed on the Technology

Center's Silicon Graphics Onyx supercomputer. With eight 200-

MHz processors, four gigabytes of

RAM and three graphics engines, the SGI machine is used for its processing speed, graphics capa- bilities and memory capacity in handling large engineering prob- lems and displaying complex 3-D images.

CAD data defining the geome- try of the MOB and cargo vessels are imported into the Onyx in the form of DXF and IGES files from

Sener's FORAN naval design and modeling system. Simplified forms of the geometry are used to create response amplitude opera- tors (RAO) in all six degrees of freedom (for the ship's roll, pitch, heave, surge and sway) in WAMIT, a wave-body interaction program from the Massachusetts Institute of Technology.

The motions and geometries all come together in ADAMS, where cargo transfer operations are ana- lyzed for displacements, forces, accelerations and loads on various components and subsystems. This data can be displayed as plots for evaluating the various parame- ters. Also, output from ADAMS goes into the Easy Scene visualiza- tion package from Coryphaeus Inc. to create a realistic animated motion picture of the action that can be viewed to understand over- all motion. Areas can reportedly be magnified or cross-sectioned for closer examination. Because the simulation is physics-driven and the action is based on mathemati- (Continued on page 78)

April, 1998 67

74

74

76

76