Page 109: of Maritime Reporter Magazine (June 1998)

Read this page in Pdf, Flash or Html5 edition of June 1998 Maritime Reporter Magazine

PROPULSION UPDATE

Classic Basile Designed Tugs lor Chabert

Port Captain Wade Bruce reports that Scotty Chabert's new 84 x 27 x 11.6-ft. (25.6 x 8.2 x 3.5- m) tugs will feature forward house and towing winches. Designed by naval architect Frank Basile of

Houma, La., the boats are being built at R&S Fabricators in

Lockport.

Powered by a pair of KTA38M2 engines rated at 1,200-hp driving at 1,800 rpm prop through Twin

Disc model MG5301 6:1 reduction gears.

The tugs will be involved in rig towing and anchor handling.

Frank Basile has a long histo- ry in workboat design, beginning his career with Avondale Shipyard in 1947.

The Chabert tug design has its origins in a pair of 80 x 25 ft. (24.3 x 8 m) boats designed by Mr.

Basile in the 1970s for Allied

Towing out of Norfolk. (

Since then he has designed an 84 x 25-ft. (25.6 x 8-m) version, and in 1980 he designed and built at his Modern Mariner Power Inc. yard, an 84 x 27-ft. (25.6 x 8.2-m) version for St. Phillips Towing. He then built two more of the popular tugs for a paper company in

Chesapeake Bay.

When Scotty Chabert came looking for a tug of that general size, he brought out the original pre CAD drawings and input the numbers to his computer.

Accordiong to Mr. Chabert, a scan won't work, so the actual design work has to be put into the

CAD program. Some modifications were required to meet regulatory changes over the years, but the tug had been well designed in the first place and the new boat will have the same general appearance.

But, said Mr. Basile, marine engines have come a long way, and the Cummins KTA38-M2 engines going in this 2,400-hp boat are about 20 percent lighter for their hp than the engines that he was putting in the original boats of this design. This allows for increased tankage and more fuel.

At the same time the modern engine gains another 20 percent in fuel efficiency.

This means that with the 50,000 gallons of fuel that this boat can carry it will be suitable for towing

June, 1998 to any of the Caribbean Islands although its intended work will be in the Gulf of Mexico oil patch.

The engines will turn 79-in. pro- pellers in 80-in. kort nozzles.

Circle 63 on Reader Service Card

A T E X C H A N G E R S

Operate More Efficiently At Lower Cost

With Tranter Heat Exchangers

HEAT RECOVERY FROM CONDENSATE HEATING RECOVERED OIL ^—»-FRESH WATER

SUPERCHANGER HEATING SHIP'S

UNIT WATER SERVICE

CENTRAL FRESH

WATER COOLER

PL£TECOIL HEATED TANK FOR

BANK RECOVERED OIL

SPILLS

SEAWATER SUPERCHANGER /

OR FRESH UNIT

WATER

COOLING MAIN

ENGINE LUBE OIL

SUPERCHANGER

UNIT

DIESEL ENGINE

SEAWATER OR

FRESH WATER

FRESH WATER

STORAGE TANK

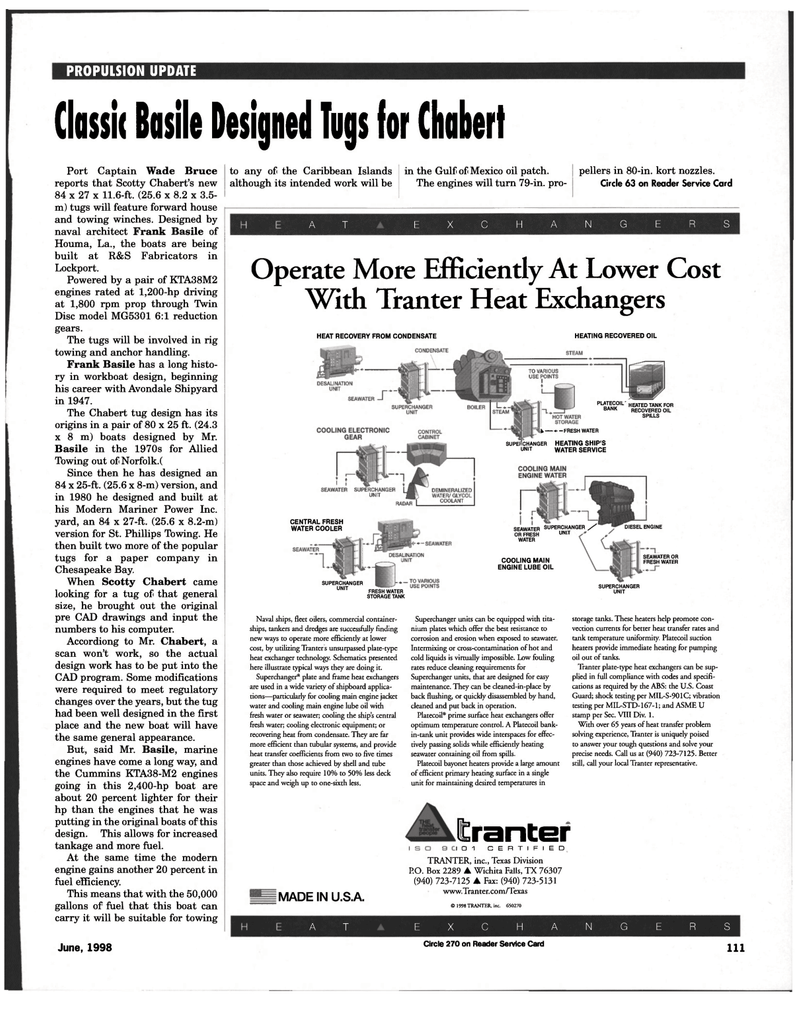

Naval ships, fleet oilers, commercial container- ships, tankers and dredges are successfully finding new ways to operate more efficiently at lower cost, by utilizing Tranter s unsurpassed plate-type heat exchanger technology. Schematics presented here illustrate typical ways they are doing it.

Superchanger® plate and frame heat exchangers are used in a wide variety of shipboard applica- tions—particularly for cooling main engine jacket water and cooling main engine lube oil with fresh water or seawater; cooling the ship's central fresh water; cooling electronic equipment; or recovering heat from condensate. They are far more efficient than tubular systems, and provide heat transfer coefficients from two to five times greater than those achieved by shell and tube units. They also require 10% to 50% less deck space and weigh up to one-sixth less.

Superchanger units can be equipped with tita- nium plates which offer the best resistance to corrosion and erosion when exposed to seawater.

Intermixing or cross-contamination of hot and cold liquids is virtually impossible. Low fouling rates reduce cleaning requirements for

Superchanger units, that are designed for easy maintenance. They can be cleaned-in-place by back flushing, or quickly disassembled by hand, cleaned and put back in operation.

Platecoil® prime surface heat exchangers offer optimum temperature control. A Platecoil bank- in-tank unit provides wide interspaces for effec- tively passing solids while efficiently heating seawater containing oil from spills.

Platecoil bayonet heaters provide a large amount of efficient primary heating surface in a single unit for maintaining desired temperatures in

SUPERCHANGER

UNIT storage tanks. These heaters help promote con- vection currents for better heat transfer rates and tank temperature uniformity. Platecoil suction heaters provide immediate heating for pumping oil out of tanks.

Tranter plate-type heat exchangers can be sup- plied in full compliance with codes and specifi- cations as required by the ABS: the U.S. Coast

Guard; shock testing per MIL-S-901C; vibration testing per MIL-STD-167-1; and ASME U stamp per Sec. VIII Div. 1.

With over 65 years of heat transfer problem solving experience, Tranter is uniquely poised to answer your tough questions and solve your precise needs. Call us at (940) 723-7125. Better still, call your local Tranter representative. tranter

I • 1 CERTIFIED

MADE IN U.S.A.

TRANTER, inc., Texas Division

P.O. Box 2289 A Wichita Falls, TX 76307 (940) 723-7125 A Fax: (940) 723-5131 www.Tranter.com/Texas © 1998 TRANTER, inc. 650270

A T E X c H A N G E R S

Circle 270 on Reader Service Card 111

108

108

110

110