Page 49: of Maritime Reporter Magazine (December 1998)

Read this page in Pdf, Flash or Html5 edition of December 1998 Maritime Reporter Magazine

Lindenau Werft

Oil and chemical tanker

Carl Buttner

Shipbuilder

Vessel name

Vessel type

Owner/ operator

Bremen-based Carl Buttner's active support both of German con- struction and of the innovative

Tanker Class 2000 concept devised by the Lindenau yard at Kiel has found new expression in the 13,000-dwt oil and chemical carri- er Hornisse. Signifying a further stage in the strengthening of

Buttner's modern fleet engaged in the European shortsea and distrib- utive trades, Hornisse represents an advance in home-grown tech- nology as the first in the second- generation series of Tanker Class 2000 tonnage.

Second and third newbuilds have been ordered by the

Changjiang National Shipping

Corp. of China, while the fourth vessel has also been booked for

Buttner's operations. All four ships are identical in main dimensions and similar in outfit, although the technical specifications differ in accordance with the respective owners' trading needs.

As an entrant into a market sce- nario characterized by high expec- tations of service and very demanding operating profiles,

Hornisse is distinguished by an especially attractive ratio between economical speed and power, flexi- bility in the range and degree of segregation of cargoes carried, level of automation, fast rates of loading and discharge, maneuver- ability characteristics, and tuning to future as well as existing legis- lation.

The versatility of the ship reflects the mindset of the owner and mirrors the technical stance of the shipyard, which currently offers its Tanker Class 2000 in no less than 147 high-grade variants in around one dozen sizes from 1,500-dwt to 32,500-dwt.

Designed and built under the supervision and approval of

Germanischer Lloyd as well as the

Marine Insurance and Safety

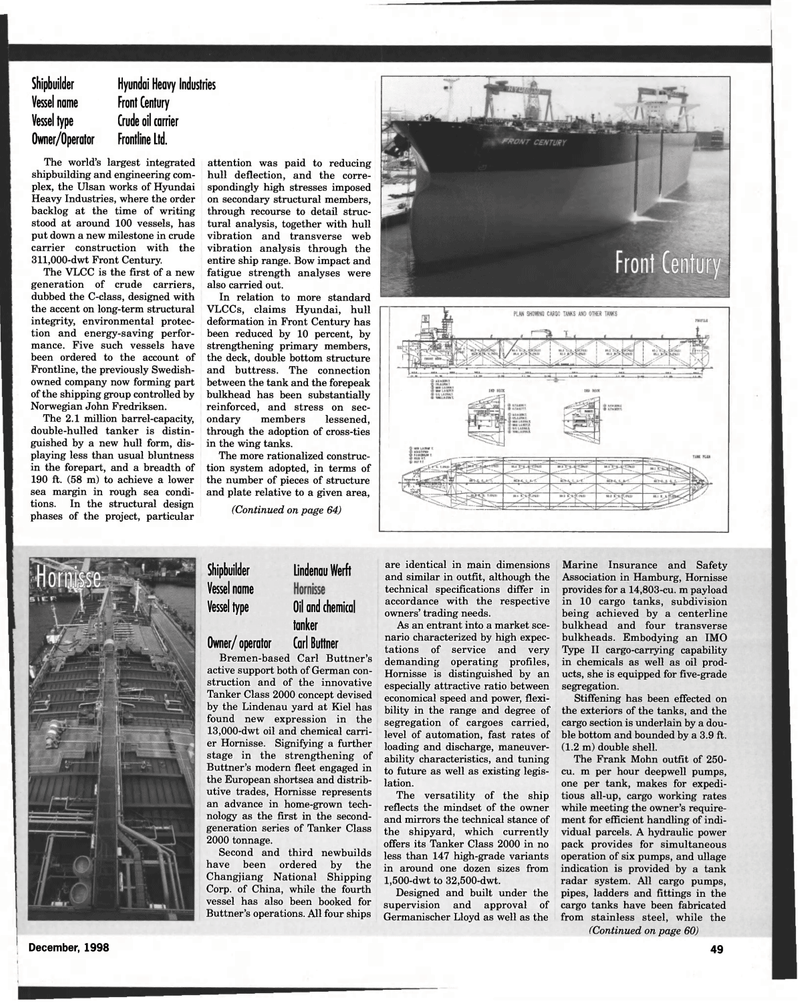

Association in Hamburg, Hornisse provides for a 14,803-cu. m payload in 10 cargo tanks, subdivision being achieved by a centerline bulkhead and four transverse bulkheads. Embodying an IMO

Type II cargo-carrying capability in chemicals as well as oil prod- ucts, she is equipped for five-grade segregation.

Stiffening has been effected on the exteriors of the tanks, and the cargo section is underlain by a dou- ble bottom and bounded by a 3.9 ft. (1.2 m) double shell.

The Frank Mohn outfit of 250- cu. m per hour deep well pumps, one per tank, makes for expedi- tious all-up, cargo working rates while meeting the owner's require- ment for efficient handling of indi- vidual parcels. A hydraulic power pack provides for simultaneous operation of six pumps, and ullage indication is provided by a tank radar system. All cargo pumps, pipes, ladders and fittings in the cargo tanks have been fabricated from stainless steel, while the (Continued on page 60)

Shipbuilder Hyundai Heavy Industries

Vessel name Front Century

Vessel type Crude oil carrier

Owner/Operator Frontline Ltd.

The world's largest integrated shipbuilding and engineering com- plex, the Ulsan works of Hyundai

Heavy Industries, where the order backlog at the time of writing stood at around 100 vessels, has put down a new milestone in crude carrier construction with the 311,000-dwt Front Century.

The VLCC is the first of a new generation of crude carriers, dubbed the C-class, designed with the accent on long-term structural integrity, environmental protec- tion and energy-saving perfor- mance. Five such vessels have been ordered to the account of

Frontline, the previously Swedish- owned company now forming part of the shipping group controlled by

Norwegian John Fredriksen.

The 2.1 million barrel-capacity, double-hulled tanker is distin- guished by a new hull form, dis- playing less than usual bluntness in the forepart, and a breadth of 190 ft. (58 m) to achieve a lower sea margin in rough sea condi- tions. In the structural design phases of the project, particular attention was paid to reducing hull deflection, and the corre- spondingly high stresses imposed on secondary structural members, through recourse to detail struc- tural analysis, together with hull vibration and transverse web vibration analysis through the entire ship range. Bow impact and fatigue strength analyses were also carried out.

In relation to more standard

VLCCs, claims Hyundai, hull deformation in Front Century has been reduced by 10 percent, by strengthening primary members, the deck, double bottom structure and buttress. The connection between the tank and the forepeak bulkhead has been substantially reinforced, and stress on sec- ondary members lessened, through the adoption of cross-ties in the wing tanks.

The more rationalized construc- tion system adopted, in terms of the number of pieces of structure and plate relative to a given area, (Continued on page 64)

December, 1998 49

48

48

50

50