Page 52: of Maritime Reporter Magazine (November 1999)

Read this page in Pdf, Flash or Html5 edition of November 1999 Maritime Reporter Magazine

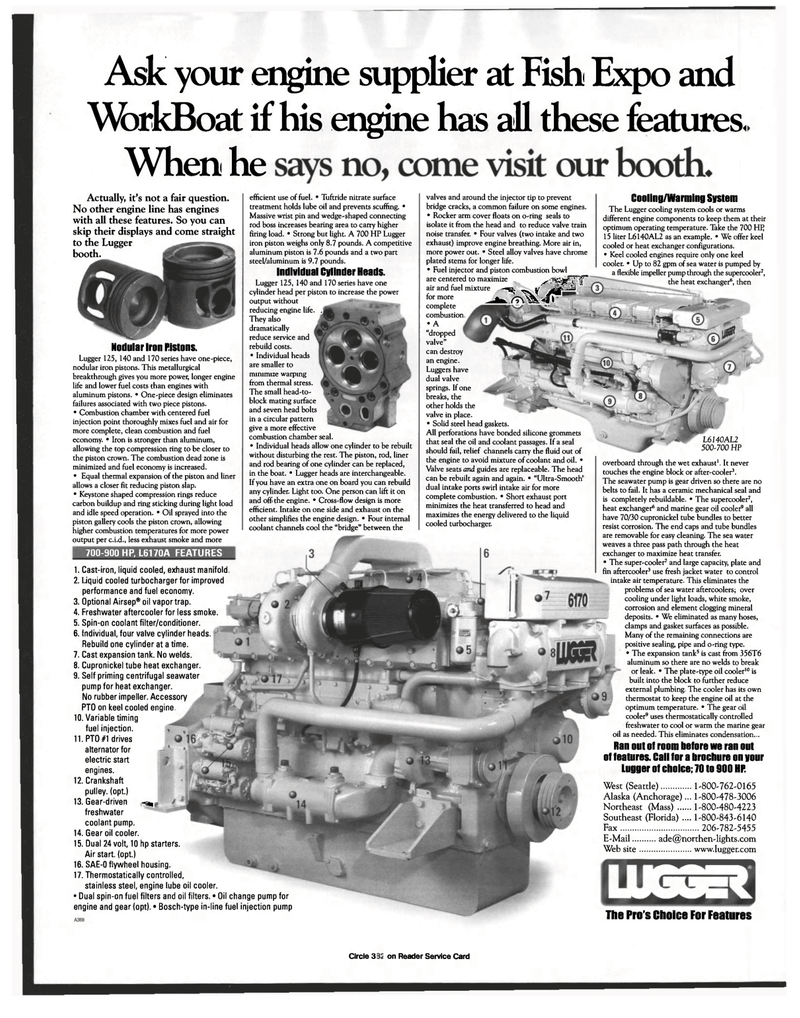

Ask your engine supplier at Fish Expo and WbrkBoat if his engine has all these features When he Actually, it's not a fair question. No other engine line has engines with all these features. So you can skip their displays and come straight to the Lugger booth. Nodular Iron Pistons. Lugger 125, 140 and 170 series have one-piece, nodular iron pistons. This metallurgical breakthrough gives you more power, longer engine life and lower fuel costs than engines with aluminum pistons. ? One-piece design eliminates failures associated with two piece pistons. ? Combustion chamber with centered fuel injection point thoroughly mixes fuel and air for more complete, clean combustion and fuel economy. ? Iron is stronger than aluminum, allowing the top compression ring to be closer to the piston crown. The combustion dead zone is minimized and fuel economy is increased. ? Equal thermal expansion of the piston and liner allows a closer fit reducing piston slap. ? Keystone shaped compression rings reduce carbon buildup and ring sticking during light load and idle speed operation. ? Oil sprayed into the piston gallery cools the piston crown, allowing higher combustion temperatures for more power output per c.i.d., less exhaust smoke and more 700-900 HP, L6170A FEATURES 1. Cast-iron, liquid cooled, exhaust manifold 2. Liquid cooled turbocharger for improved performance and fuel economy. 3. Optional Airsep® oil vapor trap. 4. Freshwater aftercooler for less smoke. 5. Spin-on coolant filter/conditioner. 6. Individual, four valve cylinder heads. Rebuild one cylinder at a time. 7. Cast expansion tank. No welds. 8. Cupronickel tube heat exchanger. 9. Self priming centrifugal seawater pump for heat exchanger. No rubber impeller. Accessory PT0 on keel cooled engine 10. Variable timing efficient use of fuel. ? Tuftride nitrate surface treatment holds lube oil and prevents scuffing. ? Massive wrist pin and wedge-shaped connecting rod boss increases bearing area to carry higher firing load. ? Strong but light. A 700 HP Lugger iron piston weighs only 8.7 pounds. A competitive aluminum piston is 7.6 pounds and a two part steel/aluminum is 9.7 pounds. Individual Cylinder Heads. Lugger 125, 140 and 170 series have one cylinder head per piston to increase the power output without reducing engine life. , They also dramatically reduce service and rebuild costs. ? Individual heads are smaller to minimize warping from thermal stress. The small head-to-block mating surface and seven head bolts in a circular pattern give a more effective combustion chamber seal. ? Individual heads allow one cylinder to be rebuilt without disturbing the rest. The piston, rod, liner and rod bearing of one cylinder can be replaced, in the boat. ? Lugger heads are interchangeable. If you have an extra one on board you can rebuild any cylinder. Light too. One person can lift it on and off the engine. ? Cross-flow design is more efficient. Intake on one side and exhaust on the other simplifies the engine design. ? Four internal coolant channels cool the "bridge" between the valves and around the injector tip to prevent bridge cracks, a common failure on some engines. ? Rocker arm cover floats on o-ring seals to isolate it from the head and to reduce valve train noise transfer. ? Four valves (two intake and two exhaust) improve engine breathing. More air in, more power out. ? Steel alloy valves have chrome plated stems for longer life. ? Fuel injector and piston combustion bowl are centered to maximize _ ^SSslPH?"*' air and fuel mixture tfjpKi for more /» complete combustion. ? A "dropped valve" can destroy an engine. Luggers have dual valve springs. If one breaks, the other holds the valve in place. ? Solid steel head gaskets. All perforations have bonded silicone grommets that seal the oil and coolant passages. If a seal should fail, relief channels carry the fluid out of the engine to avoid mixture of coolant and oil. ? Valve seats and guides are replaceable. The head can be rebuilt again and again. ? "Ultra-Smooth' dual intake ports swirl intake air for more complete combustion. ? Short exhaust port minimizes the heat transferred to head and maximizes the energy delivered to the liquid cooled turbocharger. Cooling/Warming System The Lugger cooling system cools or warms different engine components to keep them at their optimum operating temperature. Take the 700 HFJ 15 liter L6140AL2 as an example. ? We offer keel cooled or heat exchanger configurations. ? Keel cooled engines require only one keel cooler. ? Up to 82 gpm of sea water is pumped by a flexible impeller pump through the supercooler7, the heat exchanger6, then fuel injection. 11. PTO #1 drives alternator for electric start engines. 12. Crankshaft pulley, (opt.) 13. Gear-driven ^ freshwater coolant pump. 14. Gear oil cooler. 15. Dual 24 volt, 10 hp starters. Air start, (opt.) 16. SAE-0 flywheel housing. 17. Thermostatically controlled, stainless steel, engine lube oil cooler. ? Dual spin-on fuel filters and oil filters. ? Oil change pump for engine and gear (opt). ? Bosch-type in-line fuel injection pump L6140AL2 500-700 HP overboard through the wet exhaust1. It never touches the engine block or after-cooler3. The seawater pump is gear driven so there are no belts to fail. It has a ceramic mechanical seal and is completely rebuildable. ? The supercooler7, heat exchanger6 and marine gear oil cooler9 all have 70/30 cupronickel tube bundles to better resist corrosion. The end caps and tube bundles are removable for easy cleaning. The sea water weaves a three pass path through the heat exchanger to maximize heat transfer. ? The super-cooler7 and large capacity, plate and fin aftercooler3 use fresh jacket water to control intake air temperature. This eliminates the problems of sea water aftercoolers; over cooling under light loads, white smoke, corrosion and element clogging mineral deposits. ? We eliminated as many hoses, clamps and gasket surfaces as possible. Many of the remaining connections are positive sealing, pipe and o-ring type. ? The expansion tank5 is cast from 356T6 aluminum so there are no welds to break or leak. ? The plate-type oil cooler10 is built into the block to further reduce external plumbing. The cooler has its own thermostat to keep the engine oil at the optimum temperature. ? The gear oil cooler9 uses thermostatically controlled freshwater to cool or warm the marine gear oil as needed. This eliminates condensation... Ran out of room before we ran out of features. Call for a brochure on your Lugger of choice; 70 to 900 HP. West (Seattle) 1-800-762-0165 Alaska (Anchorage)... 1-800-478-3006 Northeast (Mass) 1-800-480-4223 Southeast (Florida) .... 1-800-843-6140 Fax 206-782-5455 E-Mail [email protected] Web site www.lugger.com The Pro's Choice For Features Circle 300 on Reader Service Card

51

51

53

53