Page 58: of Maritime Reporter Magazine (March 2001)

Read this page in Pdf, Flash or Html5 edition of March 2001 Maritime Reporter Magazine

IMSBiflSI

UQH-TECH MANOEUVRING EQUIPMENT

Samsung Delivers Excellence OOCL Los Angeles

Stop rust PERMANENTLY with

POR-15® MARINE, a rock-hard yet flexible coating that won't crack, chip, or peel, NOTHING

ON EARTH compares to POR-15®

MARINE for durability. We guarantee it unconditionally!

CALL TODAY FOR FREE CATALOG 1-800-457-6715

Shop our on-line catalog: www.pori 5-marine.com

The fish can't believe their ey

Great Ships of 2000

Barkemeyer Schiffstechnik GmbH & Co. KG., Birkenweg 11, D-21465 Reinbek •••••^ Tel.: +49 (0)40 7118020, Fax:+49 (0)40 7110086

A"^16 E-mail: [email protected], lnternet:www.barkemeyer.com

Now fi's your turn.

Insist upon

Barkemeyer ^ manoeuvring ^ equipment 58 www.maritimetoday.com

Circle 208 on Reader Service Card

Maritime Reporter & Engineering News

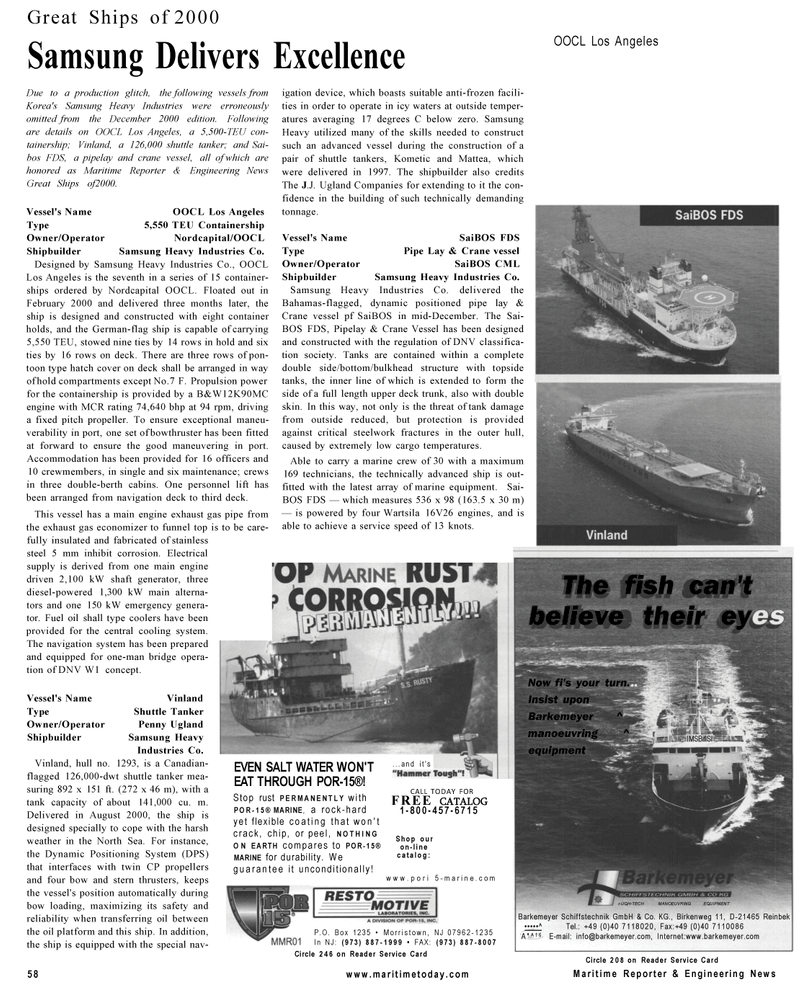

Vessel's Name Vinland

Type Shuttle Tanker

Owner/Operator Penny Ugland

Shipbuilder Samsung Heavy

Industries Co.

Vinland, hull no. 1293, is a Canadian- flagged 126,000-dwt shuttle tanker mea- suring 892 x 151 ft. (272 x 46 m), with a tank capacity of about 141,000 cu. m.

Delivered in August 2000, the ship is designed specially to cope with the harsh weather in the North Sea. For instance, the Dynamic Positioning System (DPS) that interfaces with twin CP propellers and four bow and stern thrusters, keeps the vessel's position automatically during bow loading, maximizing its safety and reliability when transferring oil between the oil platform and this ship. In addition, the ship is equipped with the special nav- igation device, which boasts suitable anti-frozen facili- ties in order to operate in icy waters at outside temper- atures averaging 17 degrees C below zero. Samsung

Heavy utilized many of the skills needed to construct such an advanced vessel during the construction of a pair of shuttle tankers, Kometic and Mattea, which were delivered in 1997. The shipbuilder also credits

The J.J. Ugland Companies for extending to it the con- fidence in the building of such technically demanding tonnage.

Vessel's Name SaiBOS FDS

Type Pipe Lay & Crane vessel

Owner/Operator SaiBOS CML

Shipbuilder Samsung Heavy Industries Co.

Samsung Heavy Industries Co. delivered the

Bahamas-flagged, dynamic positioned pipe lay &

Crane vessel pf SaiBOS in mid-December. The Sai-

BOS FDS, Pipelay & Crane Vessel has been designed and constructed with the regulation of DNV classifica- tion society. Tanks are contained within a complete double side/bottom/bulkhead structure with topside tanks, the inner line of which is extended to form the side of a full length upper deck trunk, also with double skin. In this way, not only is the threat of tank damage from outside reduced, but protection is provided against critical steelwork fractures in the outer hull, caused by extremely low cargo temperatures.

Able to carry a marine crew of 30 with a maximum 169 technicians, the technically advanced ship is out- fitted with the latest array of marine equipment. Sai-

BOS FDS — which measures 536 x 98 (163.5 x 30 m) — is powered by four Wartsila 16V26 engines, and is able to achieve a service speed of 13 knots.

Due to a production glitch, the following vessels from

Korea's Samsung Heavy Industries were erroneously omitted from the December 2000 edition. Following are details on OOCL Los Angeles, a 5,500-TEU con- tainership; Vinland, a 126,000 shuttle tanker; and Sai- bos FDS, a pipelay and crane vessel, all of which are honored as Maritime Reporter & Engineering News

Great Ships of2000.

Vessel's Name OOCL Los Angeles

Type 5,550 TEU Containership

Owner/Operator Nordcapital/OOCL

Shipbuilder Samsung Heavy Industries Co.

Designed by Samsung Heavy Industries Co., OOCL

Los Angeles is the seventh in a series of 15 container- ships ordered by Nordcapital OOCL. Floated out in

February 2000 and delivered three months later, the ship is designed and constructed with eight container holds, and the German-flag ship is capable of carrying 5,550 TEU, stowed nine ties by 14 rows in hold and six ties by 16 rows on deck. There are three rows of pon- toon type hatch cover on deck shall be arranged in way of hold compartments except No.7 F. Propulsion power for the containership is provided by a B&W12K90MC engine with MCR rating 74,640 bhp at 94 rpm, driving a fixed pitch propeller. To ensure exceptional maneu- verability in port, one set of bowthruster has been fitted at forward to ensure the good maneuvering in port.

Accommodation has been provided for 16 officers and 10 crewmembers, in single and six maintenance; crews in three double-berth cabins. One personnel lift has been arranged from navigation deck to third deck.

This vessel has a main engine exhaust gas pipe from the exhaust gas economizer to funnel top is to be care- fully insulated and fabricated of stainless steel 5 mm inhibit corrosion. Electrical supply is derived from one main engine driven 2,100 kW shaft generator, three diesel-powered 1,300 kW main alterna- tors and one 150 kW emergency genera- tor. Fuel oil shall type coolers have been provided for the central cooling system.

The navigation system has been prepared and equipped for one-man bridge opera- tion of DNV W1 concept.

Circle 246 on Reader Service Card

EVEN SALT WATER WON'T

EAT THROUGH POR-15®! ...and it's

P.O. Box 1235 • Morristown, NJ 07962-1235

In NJ: (973) 887-1999 • FAX: (973) 887-8007

57

57

59

59