Page 3rd Cover: of Maritime Reporter Magazine (February 2003)

Read this page in Pdf, Flash or Html5 edition of February 2003 Maritime Reporter Magazine

Special Advertising Section for Mascoat Products • www.deltacoat.com

A Proven, New Approach for Vessel Insulation

Vessel insulation has changed very little in many years. Normally hidden from direct view, thermal insulation systems can become ineffective over time due to poor installation, vibration or moisture intrusion. In fact, if moisture is ever introduced into the insula- tion from a leak, poor installation, or inade- quate repair job, the conventional insulation methods are worse than if insulation had not been used at all.

Common Methods of

Thermal Insulation Inside Vessels

In the past, most shipyards and owners have been at the mercy of technology that only incorporates one aspect of heat/cold transfer known as conduction. These insulation sys- tems have been designed to retard heat and cold over time and treat & solve heat transfer as a symptom, not as the inherit problem.

Common pin-and-blanket insulation found on most vessels requires the painstaking task of bringing the insulation material into an area, placement of attachment pins, cutting, tapping and finally fitting of the insulation.

With this multi-step process, which is quite labor intensive, only around ten square feet (one square meter) of insulation can be installed in a one-man hour time period. If not managed well, this process could lead to dramatic man-hour cost overruns. In addi- tion, over time these blanket insulation sys- tems lose their power to retard heat/cold and therefore are a direct gate for thermal transfer into the vessel.

Another common way of insulating vessels is to use foam-in-place insulation systems.

This system requires special equipment, high- ly trained personnel and usually complete shut down of other ongoing tasks of a job during an application due to safety and PPE (personnel protection equipment) concerns.

Since foam systems work on chemical reac- tions of component products that are highly flammable, these systems do not pass the cur- rent FTP codes and can in fact contribute to the dangers and damage caused by fire. Just recently, there have been two incidents of fires onboard crew vessels where foam insulation contributed to death.

Other problems of these foam systems include, outsourcing of personnel for an application, bonding and detachment issues, degradation of the insulation due to vibra- tion, and most importantly corrosion under insulation. Though this is a cheaper method of insulating, foam systems have been highly scrutinized as an antiquated technology.

A New Approach to Thermal

Insulation and Protection of Vessels

In 1995, Mascoat Products, Houston,

Texas, developed a new spray application thermal barrier system, Delta T Marine

Insulating Coating, which has been success- fully used worldwide on more than 200 ves- sels. The system is a water-based acrylic binder that encapsulates air-filled ceramic insulating particles to help reduce or elimi- nate most radiant heat/cold transmission.

Delta T Marine is sprayed on the inside shell of most modern vessels at a thickness of 20- 60 mils (0.5-1.5mm). By direct bonding, a substrate becomes thoroughly protected and eliminates the potential of development for

Corrosion Under Insulation. Vessels employ- ing the coating system are now insulated and protected with a thermal transfer rating of

RvE 9-13 factor when compared with con- ventional insulation. Thus, this spray system used alone or in conjunction with conven- tional wallboard provides equal or better pro- tection of thermal transfer at a reduced cost and time effort.

Most shipyards that have used the Delta T

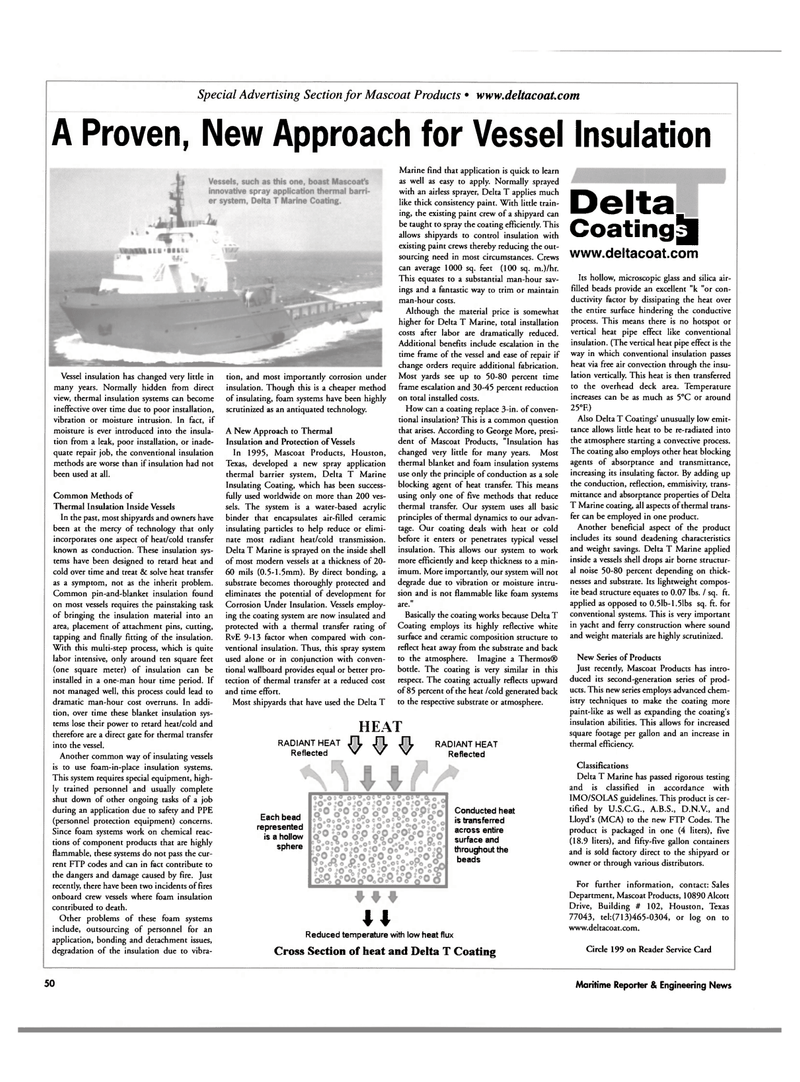

Each bead represented is a hollow sphere

Marine find that application is quick to learn as well as easy to apply. Normally sprayed with an airless sprayer, Delta T applies much like thick consistency paint. With little train- ing, the existing paint crew of a shipyard can be taught to spray the coating efficiently. This allows shipyards to control insulation with existing paint crews thereby reducing the out- sourcing need in most circumstances. Crews can average 1000 sq. feet (100 sq. m.)/hr.

This equates to a substantial man-hour sav- ings and a fantastic way to trim or maintain man-hour costs.

Although the material price is somewhat higher for Delta T Marine, total installation costs after labor are dramatically reduced.

Additional benefits include escalation in the time frame of the vessel and ease of repair if change orders require additional fabrication.

Most yards see up to 50-80 percent time frame escalation and 30-45 percent reduction on total installed costs.

How can a coating replace 3-in. of conven- tional insulation? This is a common question that arises. According to George More, presi- dent of Mascoat Products, "Insulation has changed very little for many years. Most thermal blanket and foam insulation systems use only the principle of conduction as a sole blocking agent of heat transfer. This means using only one of five methods that reduce thermal transfer. Our system uses all basic principles of thermal dynamics to our advan- tage. Our coating deals with heat or cold before it enters or penetrates typical vessel insulation. This allows our system to work more efficiently and keep thickness to a min- imum. More importantly, our system will not degrade due to vibration or moisture intru- sion and is not flammable like foam systems are."

Basically the coating works because Delta T

Coating employs its highly reflective white surface and ceramic composition structure to reflect heat away from the substrate and back to the atmosphere. Imagine a Thermos® bottle. The coating is very similar in this respect. The coating actually reflects upward of 85 percent of the heat /cold generated back to the respective substrate or atmosphere.

Conducted heat is transferred across entire surface and throughout the beads

Delta

Coatingjjjj www.deltacoat.com

Its hollow, microscopic glass and silica air- filled beads provide an excellent "k "or con- ductivity factor by dissipating the heat over the entire surface hindering the conductive process. This means there is no hotspot or vertical heat pipe effect like conventional insulation. (The vertical heat pipe effect is the way in which conventional insulation passes heat via free air convection through the insu- lation vertically. This heat is then transferred to the overhead deck area. Temperature increases can be as much as 5°C or around 25°F.)

Also Delta T Coatings' unusually low emit- tance allows little heat to be re-radiated into the atmosphere starting a convective process.

The coating also employs other heat blocking agents of absorptance and transmittance, increasing its insulating factor. By adding up the conduction, reflection, emmisivity, trans- mittance and absorptance properties of Delta

T Marine coating, all aspects of thermal trans- fer can be employed in one product.

Another beneficial aspect of the product includes its sound deadening characteristics and weight savings. Delta T Marine applied inside a vessels shell drops air borne structur- al noise 50-80 percent depending on thick- nesses and substrate. Its lightweight compos- ite bead structure equates to 0.07 lbs. / sq. ft. applied as opposed to 0.51b-1.51bs sq. ft. for conventional systems. This is very important in yacht and ferry construction where sound and weight materials are highly scrutinized.

New Series of Products

Just recently, Mascoat Products has intro- duced its second-generation series of prod- ucts. This new series employs advanced chem- istry techniques to make the coating more paint-like as well as expanding the coating's insulation abilities. This allows for increased square footage per gallon and an increase in thermal efficiency.

Classifications

Delta T Marine has passed rigorous testing and is classified in accordance with

IMO/SOLAS guidelines. This product is cer- tified by U.S.C.G., A.B.S., D.N.V., and

Lloyd's (MCA) to the new FTP Codes. The product is packaged in one (4 liters), five (18.9 liters), and fifty-five gallon containers and is sold factory direct to the shipyard or owner or through various distributors.

For further information, contact: Sales

Department, Mascoat Products, 10890 Alcott

Drive, Building # 102, Houston, Texas 77043, tel:(713)465-0304, or log on to www.deltacoat.com.

Circle 199 on Reader Service Card

RADIANT HEAT

Reflected

HEAT • ft

RADIANT HEAT

Reflected 44

Reduced temperature with low heat flux

Cross Section of heat and Delta T Coating 50 Maritime Reporter & Engineering News

49

49

4th Cover

4th Cover