Page 24: of Maritime Reporter Magazine (September 2003)

Read this page in Pdf, Flash or Html5 edition of September 2003 Maritime Reporter Magazine

Marine Propulsion Annual

Payload Pivotal to Fast Sealift Ship

By David Tinsley, Technical Editor

While catamaran and multi-hull vessel technology is increasingly being explored for its potential in high- speed military and logistical support applications.

Rolls-Royce has unveiled a proposal for a fast naval sealift ship based on a monohull RoPax ferry design.

The impulse for developing a vessel type with that rare combination of exceptional speed and relatively high payload capacity originates from the changing emphasis in military support requirements, not least the deployment of rapid response forces to distant areas at short notice. The project has also been driven by a general trend towards faster combatants and the complementary need for a faster speed of back-up and replenishment.

The Rolls-Royce proposal entails a 4,000-dwt vessel of 581 ft. (177 m), capable of achieving a range of 3,600 n.m., transporting 2,500-tons of cargo at 36- knots. Short-haul operations, with a much decreased fuel volume, would allow shipment sizes up to 3,700- tons, in the case of sustaining a speed of 40 knots over 500 n.m. The comparatively high cargo capacity is not restricted by volumetric capacity, since the design encapsulates 1,800 lane-m for military vehicles and equipment.

The fast sealift vessel concept underscores Rolls-

Royce's endeavors to transfer technology across its commercial and naval businesses. It offers a pragmatic solution to emerging military needs, with the cost and time benefits of using a commercial, off-the-shelf (COTS) design of fast ferry.

It is based on the P2500 RoPax series, formulated in the late 1990s by Nordvestconsult. one of two west

Norwegian commercial ship design houses owned by the UK group. Although not built to date, the P2500 was originally developed in response to a

Mediterranean ferry operator's project requirements, and the design was tank-tested and taken through the classification process. The parameters had included a speed of 42-knots, and dimensioning for 1,500-passen-

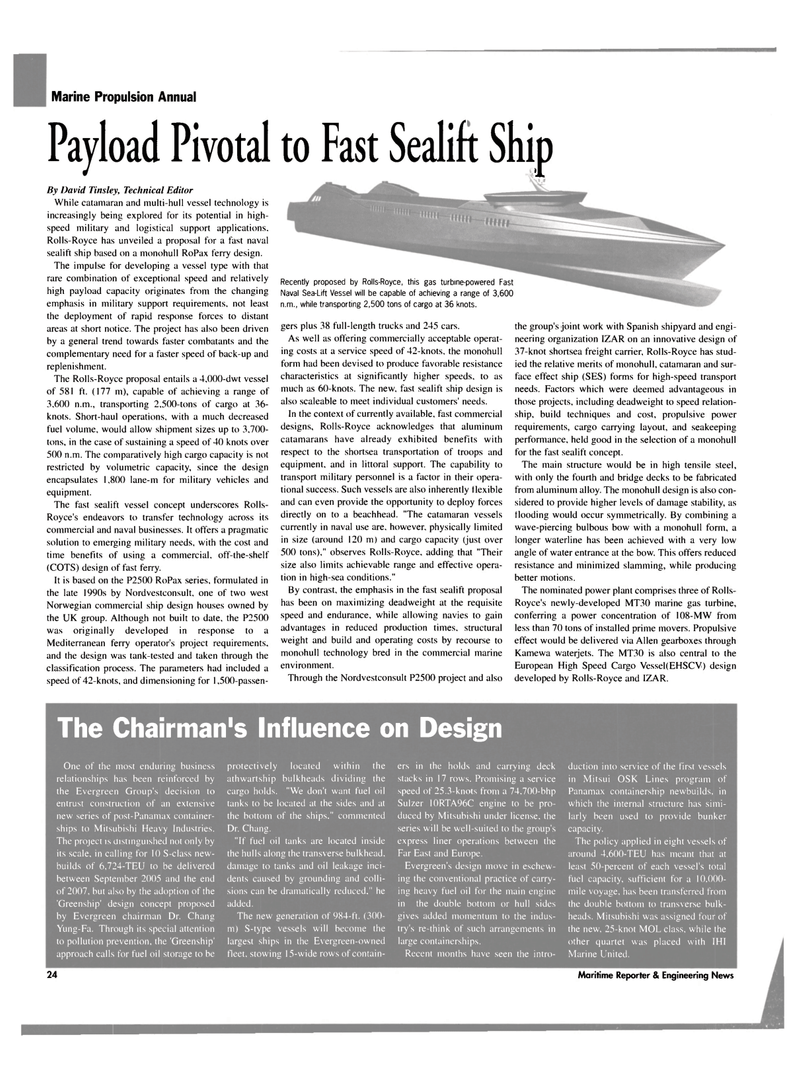

Recently proposed by Rolls-Royce, this gas turbine-powered Fast

Naval Sea-Lift Vessel will be capable of achieving a range of 3,600 n.m., while transporting 2,500 tons of cargo at 36 knots. gers plus 38 full-length trucks and 245 cars.

As well as offering commercially acceptable operat- ing costs at a service speed of 42-knots, the monohull form had been devised to produce favorable resistance characteristics at significantly higher speeds, to as much as 60-knots. The new, fast sealift ship design is also scaleable to meet individual customers' needs.

In the context of currently available, fast commercial designs, Rolls-Royce acknowledges that aluminum catamarans have already exhibited benefits with respect to the shortsea transportation of troops and equipment, and in littoral support. The capability to transport military personnel is a factor in their opera- tional success. Such vessels are also inherently flexible and can even provide the opportunity to deploy forces directly on to a beachhead. "The catamaran vessels currently in naval use are. however, physically limited in size (around 120 m) and cargo capacity (just over 500 tons)," observes Rolls-Royce, adding that "Their size also limits achievable range and effective opera- tion in high-sea conditions."

By contrast, the emphasis in the fast sealift proposal has been on maximizing deadweight at the requisite speed and endurance, while allowing navies to gain advantages in reduced production times, structural weight and build and operating costs by recourse to monohull technology bred in the commercial marine environment.

Through the Nordvestconsult P2500 project and also the group's joint work with Spanish shipyard and engi- neering organization IZAR on an innovative design of 37-knot shortsea freight carrier, Rolls-Royce has stud- ied the relative merits of monohull, catamaran and sur- face effect ship (SES) forms for high-speed transport needs. Factors which were deemed advantageous in those projects, including deadweight to speed relation- ship, build techniques and cost, propulsive power requirements, cargo carrying layout, and seakeeping performance, held good in the selection of a monohull for the fast sealift concept.

The main structure would be in high tensile steel, with only the fourth and bridge decks to be fabricated from aluminum alloy. The monohull design is also con- sidered to provide higher levels of damage stability, as flooding would occur symmetrically. By combining a wave-piercing bulbous bow with a monohull form, a longer waterline has been achieved with a very low angle of water entrance at the bow. This offers reduced resistance and minimized slamming, while producing better motions.

The nominated power plant comprises three of Rolls-

Royce's newly-developed MT30 marine gas turbine, conferring a power concentration of 108-MW from less than 70 tons of installed prime movers. Propulsive effect would be delivered via Allen gearboxes through

Kamewa waterjets. The MT30 is also central to the

European High Speed Cargo Vessel(EHSCV) design developed by Rolls-Royce and IZAR.

The Chairman's Influence on Design

One of the most enduring business relationships has been reinforced by the Evergreen Group's decision to entrust construction of an extensive new series of post-Panamax container- ships to Mitsubishi Heavy Industries.

The project is distinguished not only by its scale, in calling for 10 S-class new- builds of 6,724-TEU to be delivered between September 2005 and the end of 2007, but also by the adoption of the 'Greenship' design concept proposed by Evergreen chairman Dr. Chang

Yung-Fa. Through its special attention to pollution prevention, the 'Greenship' approach calls for fuel oil storage to be protectively located within the athwartship bulkheads dividing the cargo holds. "We don't want fuel oil tanks to be located at the sides and at the bottom of the ships." commented

Dr. Chang. "If fuel oil tanks are located inside the hulls along the transverse bulkhead, damage to tanks and oil leakage inci- dents caused by grounding and colli- sions can be dramatically reduced," he added.

The new generation of 984-ft. (300- m) S-type vessels will become the largest ships in the Evergreen-owned fleet, stowing 15-wide rows of contain- ers in the holds and carrying deck stacks in 17 rows. Promising a service speed of 25.3-knots from a 74.700-bhp

Sulzer 10RTA96C engine to be pro- duced by Mitsubishi under license, the series will be well-suited to the group's express liner operations between the

Far East and Europe.

Evergreen's design move in eschew- ing the conventional practice of carry- ing heavy fuel oil for the main engine in the double bottom or hull sides gives added momentum to the indus- try's re-think of such arrangements in large containerships.

Recent months have seen the intro- duction into service of the first vessels in Mitsui OSK Lines program of

Panamax containership newbuilds. in which the internal structure has simi- larly been used to provide bunker capacity.

The policy applied in eight vessels of around 4,600-TEU has meant that at least 50-percent of each vessel's total fuel capacity, sufficient for a 10.000- mile voyage, has been transferred from the double bottom to transverse bulk- heads. Mitsubishi was assigned four of the new. 25-knot MOL class, while the other quartet was placed with IHI

Marine United. 24 Maritime Reporter & Engineering News

23

23

25

25