Page 39: of Maritime Reporter Magazine (October 2003)

Read this page in Pdf, Flash or Html5 edition of October 2003 Maritime Reporter Magazine

Training = Efficiency

Climax's initiative is far from a tool's based solution, as the company is cur- rently putting the finishing touches on its all-encompassing training program that is designed to fill a void. Though worlds apart, the needs in the U.S. and

China, for example, are strikingly simi- lar, as the U.S. shipbuilders have watched experienced workers exit with market attrition, and a recent influx of business means a young new generation needs training.

In China the situation is different, yet similar, as a massive workforce is in need of training as the newbuild market quickly ramps up. China also realized the need to invest in modern facilities and tool systems in order to attract new, higher level customers, Gilmore said.

Through the solutions package, Climax engineers help shipbuilding and repair organizations develop cost-effective solutions for the building process, and for the retrofit or re-design of outdated equipment. The company's training offerings also help diversify the skill sets of overspecialized workers or expand the skills of under-trained machinists.

Climax Portable Machine Tools pro- vides its solutions to shipbuilders like

Northrop Grumman/Ingalls, General

Dynamics Electric Boat and Northrop

Grumman/Newport News, as well as to service organizations within these industries.

Climax Meets North Sea Challenge

A few years ago Norse Cutting &

Abandonment a.s., a service company in

Stavanger, Norway, had a contract to square up eight 5 x 10-ft. (1.5 x 3-m) steel plates that had warped after being welded into place on Odin, a freighter.

Odin was being converted into a mobile drilling rig, so the plates had to be milled within I mm and laser aligned

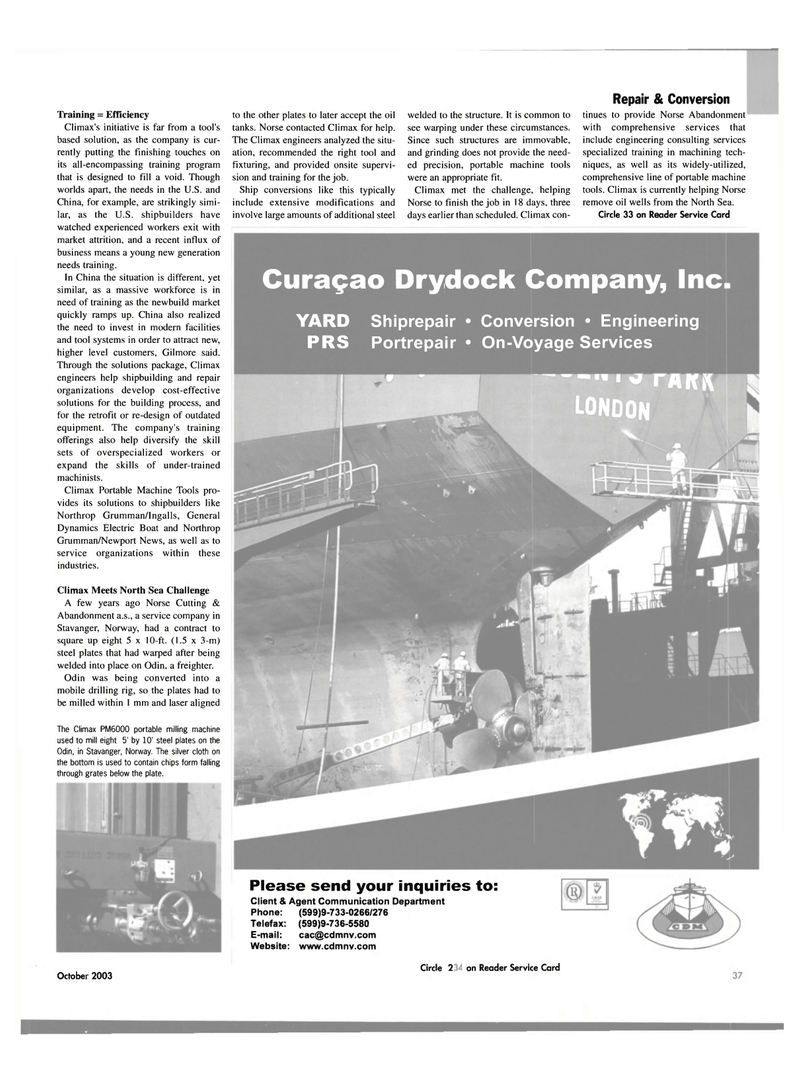

The Climax PM6000 portable milling machine used to mill eight 5' by 10' steel plates on the

Odin, in Stavanger, Norway. The silver cloth on the bottom is used to contain chips form falling through grates below the plate. to the other plates to later accept the oil tanks. Norse contacted Climax for help.

The Climax engineers analyzed the situ- ation, recommended the right tool and fixturing, and provided onsite supervi- sion and training for the job.

Ship conversions like this typically include extensive modifications and involve large amounts of additional steel welded to the structure. It is common to see warping under these circumstances.

Since such structures are immovable, and grinding does not provide the need- ed precision, portable machine tools were an appropriate fit.

Climax met the challenge, helping

Norse to finish the job in 18 days, three days earlier than scheduled. Climax con-

Repair & Conversion tinues to provide Norse Abandonment with comprehensive services that include engineering consulting services specialized training in machining tech- niques, as well as its widely-utilized, comprehensive line of portable machine tools. Climax is currently helping Norse remove oil wells from the North Sea.

Circle 33 on Reader Service Card

Please send your inquiries to:

Client & Agent Communication Department

Phone: (599)9-733-0266/276

Telefax: (599)9-736-5580

E-mail: [email protected]

Website: www.cdmnv.com

Circle 207 on Reader Service Card

October 2003 41

Curasao Drydock Company, Inc

YARD Shiprepair • Conversion • Engineering

PRS Portrepair • On-Voyage Services w TAKK

LONDON

38

38

40

40