Page 32: of Maritime Reporter Magazine (February 2004)

The Tanker Yearbook: ATB Edition

Read this page in Pdf, Flash or Html5 edition of February 2004 Maritime Reporter Magazine

tate of the Art Inland Tank Ship Tanker Technology

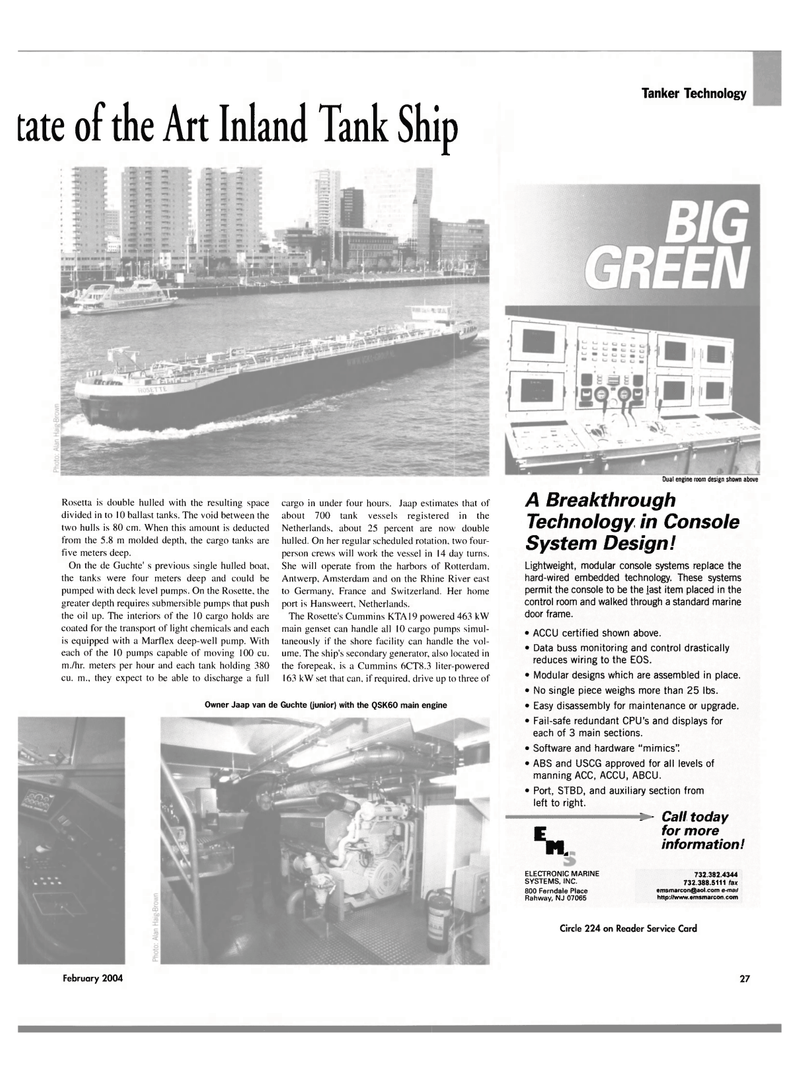

Rosetta is double hulled with the resulting space divided in to 10 ballast tanks. The void between the two hulls is 80 cm. When this amount is deducted from the 5.8 m molded depth, the cargo tanks are five meters deep.

On the de Guchte's previous single hulled boat, the tanks were four meters deep and could be pumped with deck level pumps. On the Rosette, the greater depth requires submersible pumps that push the oil up. The interiors of the 10 cargo holds are coated for the transport of light chemicals and each is equipped with a Marflex deep-well pump. With each of the 10 pumps capable of moving 100 cu. m./hr. meters per hour and each tank holding 380 cu. m., they expect to be able to discharge a full cargo in under four hours. Jaap estimates that of about 700 tank vessels registered in the

Netherlands, about 25 percent are now double hulled. On her regular scheduled rotation, two four- person crews will work the vessel in 14 day turns.

She will operate from the harbors of Rotterdam,

Antwerp, Amsterdam and on the Rhine River east to Germany, France and Switzerland. Her home port is Hansweert, Netherlands.

The Rosette's Cummins KTA19 powered 463 kW main genset can handle all 10 cargo pumps simul- taneously if the shore facility can handle the vol- ume. The ship's secondary generator, also located in the forepeak, is a Cummins 6CT8.3 liter-powered 163 kW set that can. if required, drive up to three of

Dual engine room design shown above

A Breakthrough

Technology in Console

System Design!

Lightweight, modular console systems replace the hard-wired embedded technology. These systems permit the console to be the last item placed in the control room and walked through a standard marine door frame. • ACCU certified shown above. • Data buss monitoring and control drastically reduces wiring to the EOS. • Modular designs which are assembled in place, • No single piece weighs more than 25 lbs. • Easy disassembly for maintenance or upgrade. • Fail-safe redundant CPU's and displays for each of 3 main sections. • Software and hardware "mimics". • ABS and USCG approved for all levels of manning ACC, ACCU, ABCU. • Port, STBD, and auxiliary section from left to right. » Call today for more information! V

ELECTRONIC MARINE

SYSTEMS, INC. 800 Ferndale Place

Rahway, NJ 07065 732.382.4344 732.388.5111 fax [email protected] e-mail http://www.emsmarcon.com

Circle 224 on Reader Service Card

Owner Jaap van de Guchte (junior) with the QSK60 main engine

February 2004 27

31

31

33

33