Page 35: of Maritime Reporter Magazine (May 2004)

The Propulsion Technology Yearbook

Read this page in Pdf, Flash or Html5 edition of May 2004 Maritime Reporter Magazine

Propulsion Technology

flu got

SuttfMA* added a long and deep sloping keel. The whole effect was unsatisfactory. Waterjets were investigated and the initial findings were not encouraging. They appeared expensive and inefficient below 25 knots.

However, the designer found Ultrajet units, which met price and performance requirements.

The vessel was designed in 3-D using Maxsurf Pro from formation design, with hydrostatics, damage stability, and one compartment flooding checked

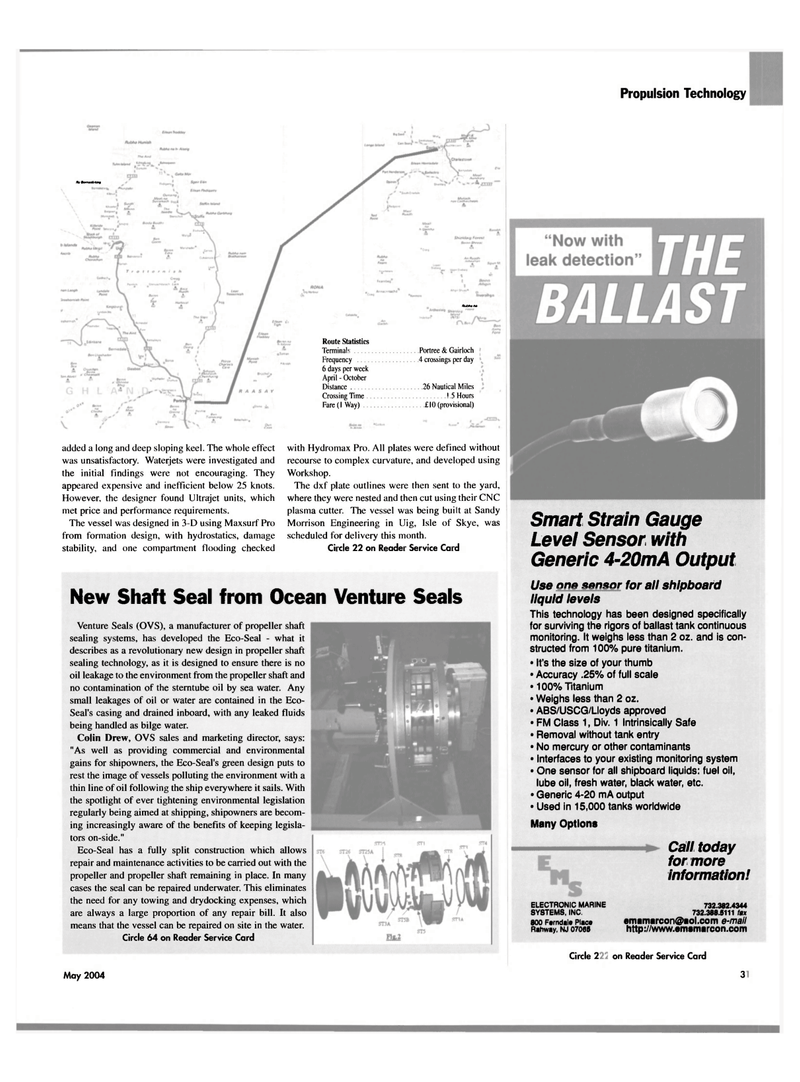

Route Statistics

Terminals Portree & Gairloch

Frequency 4 crossings per day 6 days per week

April - October

Distance 26 Nautical Miles

Crossing Time 1.5 Hours

Fare (1 Way) £10 (provisional) with Hydromax Pro. All plates were defined without recourse to complex curvature, and developed using

Workshop.

The dxf plate outlines were then sent to the yard, where they were nested and then cut using their CNC plasma cutter. The vessel was being built at Sandy

Morrison Engineering in Uig, Isle of Skye, was scheduled for delivery this month.

Circle 22 on Reader Service Card

New Shaft Seal from Ocean Venture Seals

Venture Seals (OVS), a manufacturer of propeller shaft sealing systems, has developed the Eco-Seal - what it describes as a revolutionary new design in propeller shaft sealing technology, as it is designed to ensure there is no oil leakage to the environment from the propeller shaft and no contamination of the sterntube oil by sea water. Any small leakages of oil or water are contained in the Eco-

Seal's casing and drained inboard, with any leaked fluids being handled as bilge water.

Colin Drew, OVS sales and marketing director, says: "As well as providing commercial and environmental gains for shipowners, the Eco-Seal's green design puts to rest the image of vessels polluting the environment with a thin line of oil following the ship everywhere it sails. With the spotlight of ever tightening environmental legislation regularly being aimed at shipping, shipowners are becom- ing increasingly aware of the benefits of keeping legisla- tors on-side."

Eco-Seal has a fully split construction which allows repair and maintenance activities to be carried out with the propeller and propeller shaft remaining in place. In many cases the seal can be repaired underwater. This eliminates the need for any towing and drydocking expenses, which are always a large proportion of any repair bill. It also means that the vessel can be repaired on site in the water.

Circle 64 on Reader Service Card

Smart Strain Gauge

Level Sensor with

Generic 4-20mA Output

Use one sensor for all shipboard liquid levels

This technology has been designed specifically for surviving the rigors of ballast tank continuous monitoring. It weighs less than 2 oz. and is con- structed from 100% pure titanium. • It's the size of your thumb • Accuracy .25% of full scale • 100% Titanium • Weighs less than 2 oz. • ABS/USCG/Lloyds approved • FM Class 1, Div. 1 Intrinsically Safe • Removal without tank entry • No mercury or other contaminants • Interfaces to your existing monitoring system • One sensor for all shipboard liquids: fuel oil, lube oil, fresh water, black water, etc. • Generic 4-20 mA output • Used in 15,000 tanks worldwide

Many Options

Call today for more information!

ELECTRONIC MARINE

SYSTEMS, INC. 800 Ferndale Place

Rahway, NJ 07065 732.382.4344 732.388.5111 tax [email protected] e-mail http://www.emsmarcon.com

Circle 271 on Reader Service Card

May 2004 39

34

34

36

36