Page 34: of Maritime Reporter Magazine (April 2005)

The Offshore Industry Anual

Read this page in Pdf, Flash or Html5 edition of April 2005 Maritime Reporter Magazine

The industry is beginning to take a serious look at FLNG units, some of which use ship-like tech- nology. What are the issues to consider?

New environmental regulations aimed at reducing CO2 emissions, as well as the increas- ing value of gas, are prompting operators of gas and oil fields to look for new ways of making remote gas fields economically viable. The industry has turned towards the idea of floating

LNG (FLNG) units, and several innovative solutions are beginning to gain momentum.

FLNG storage and regasification facilities, which remain permanently on station and are connected to the grid ashore via an undersea pipeline, have been put forward as one viable option. They can act as buffer storage facilities, receive LNG from shuttle tankers and offload gas to a nearby pipeline via a turret/swivel and riser arrangement. Another concept involves fit- ting an existing LNG ship with regasification facilities. In this scheme, the ship hooks up to an offshore buoy system, regassifies its own LNG cargo and pumps it into a pipeline ashore. One potential limitation of this system would be the 34 Maritime Reporter & Engineering News

Offshore Technology Annual

Moving LNG Offshore: Is it Viable?

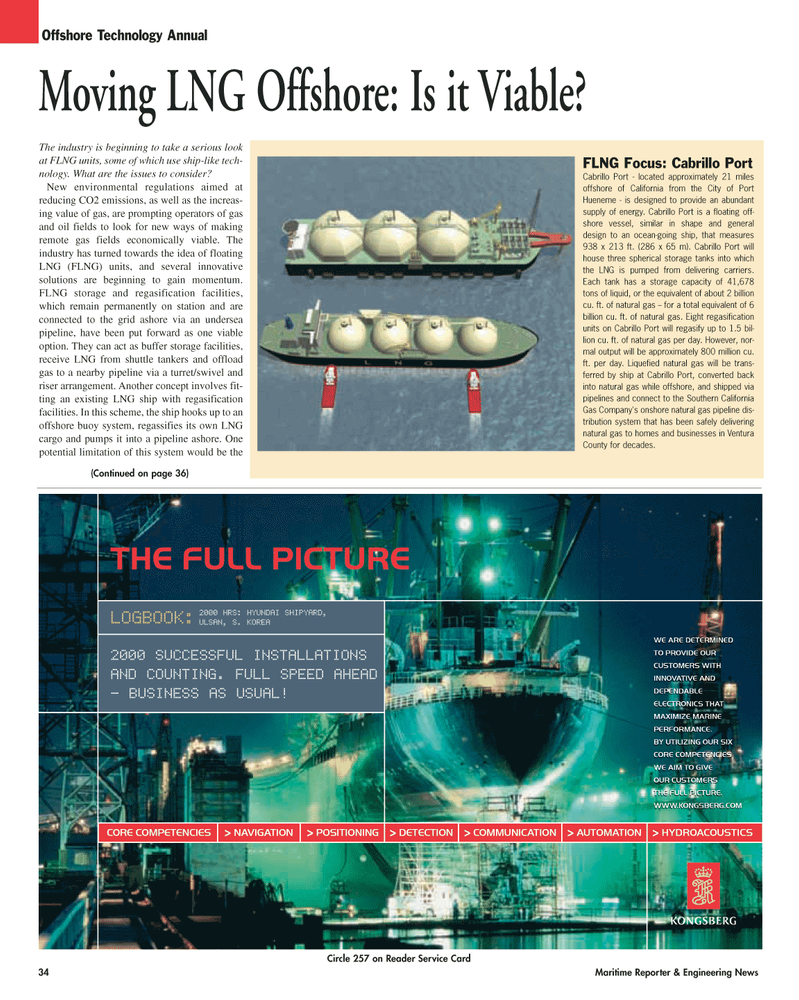

FLNG Focus: Cabrillo Port

Cabrillo Port - located approximately 21 miles offshore of California from the City of Port

Hueneme - is designed to provide an abundant supply of energy. Cabrillo Port is a floating off- shore vessel, similar in shape and general design to an ocean-going ship, that measures 938 x 213 ft. (286 x 65 m). Cabrillo Port will house three spherical storage tanks into which the LNG is pumped from delivering carriers.

Each tank has a storage capacity of 41,678 tons of liquid, or the equivalent of about 2 billion cu. ft. of natural gas -- for a total equivalent of 6 billion cu. ft. of natural gas. Eight regasification units on Cabrillo Port will regasify up to 1.5 bil- lion cu. ft. of natural gas per day. However, nor- mal output will be approximately 800 million cu. ft. per day. Liquefied natural gas will be trans- ferred by ship at Cabrillo Port, converted back into natural gas while offshore, and shipped via pipelines and connect to the Southern California

Gas Company's onshore natural gas pipeline dis- tribution system that has been safely delivering natural gas to homes and businesses in Ventura

County for decades.

CORE COMPETENCIES >

NAVIGATION >

POSITIONING >

DETECTION >

COMMUNICATION >

AUTOMATION >

HYDROACOUSTICS

THE FULL PICTURE

LOGBOOK: 2000 SUCCESSFUL INSTALLATIONS

AND COUNTING. FULL SPEED AHEAD - BUSINESS AS USUAL! 2000 HRS: HYUNDAI SHIPYARD,

ULSAN, S. KOREA

WE ARE DETERMINED

TO PROVIDE OUR

CUSTOMERS WITH

INNOVATIVE AND

DEPENDABLE

ELECTRONICS THAT

MAXIMIZE MARINE

PERFORMANCE.

BY UTILIZING OUR SIX

CORE COMPETENCIES

WE AIM TO GIVE

OUR CUSTOMERS

THE FULL PICTURE.

WWW.KONGSBERG.COM

Circle 257 on Reader Service Card (Continued on page 36)

MR APRIL 2005 #5 (33-40).qxd 4/4/2005 3:29 PM Page 2

33

33

35

35