Page 30: of Maritime Reporter Magazine (January 2010)

Ship Repair & Conversion

Read this page in Pdf, Flash or Html5 edition of January 2010 Maritime Reporter Magazine

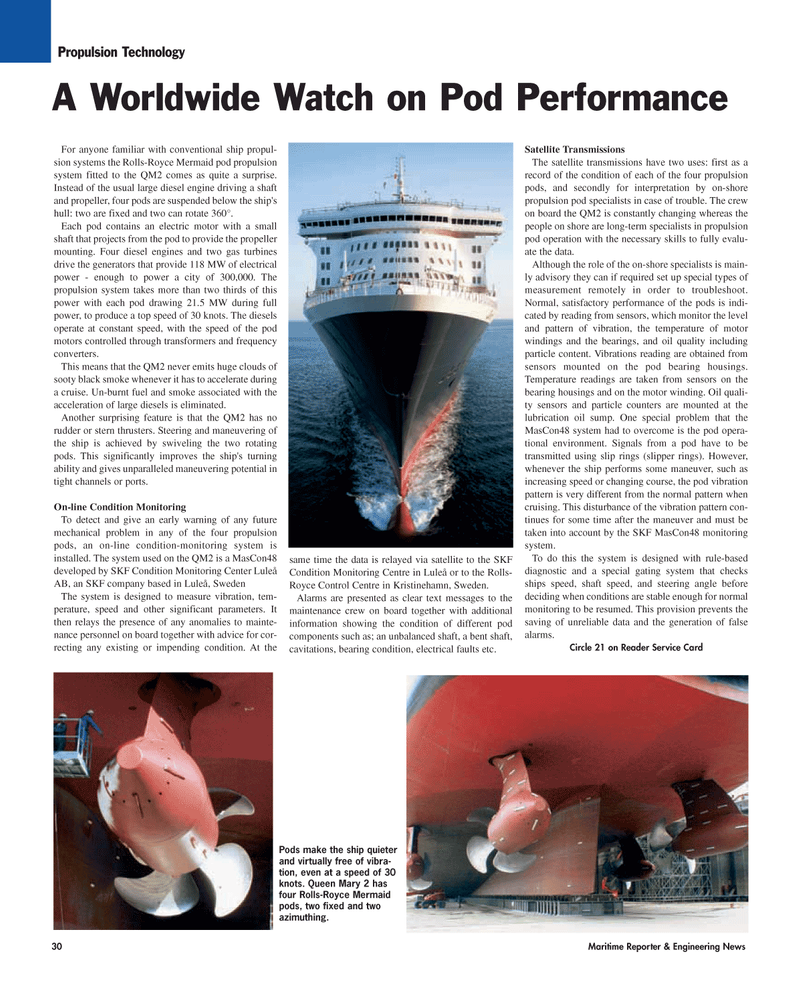

For anyone familiar with conventional ship propul- sion systems the Rolls-Royce Mermaid pod propulsion system fitted to the QM2 comes as quite a surprise.

Instead of the usual large diesel engine driving a shaft and propeller, four pods are suspended below the ship's hull: two are fixed and two can rotate 360°.

Each pod contains an electric motor with a small shaft that projects from the pod to provide the propeller mounting. Four diesel engines and two gas turbines drive the generators that provide 118 MW of electrical power - enough to power a city of 300,000. The propulsion system takes more than two thirds of this power with each pod drawing 21.5 MW during full power, to produce a top speed of 30 knots. The diesels operate at constant speed, with the speed of the pod motors controlled through transformers and frequency converters.

This means that the QM2 never emits huge clouds of sooty black smoke whenever it has to accelerate during a cruise. Un-burnt fuel and smoke associated with the acceleration of large diesels is eliminated.

Another surprising feature is that the QM2 has no rudder or stern thrusters. Steering and maneuvering of the ship is achieved by swiveling the two rotating pods. This significantly improves the ship's turning ability and gives unparalleled maneuvering potential in tight channels or ports.

On-line Condition Monitoring

To detect and give an early warning of any future mechanical problem in any of the four propulsion pods, an on-line condition-monitoring system is installed. The system used on the QM2 is a MasCon48 developed by SKF Condition Monitoring Center Luleå

AB, an SKF company based in Luleå, Sweden

The system is designed to measure vibration, tem- perature, speed and other significant parameters. It then relays the presence of any anomalies to mainte- nance personnel on board together with advice for cor- recting any existing or impending condition. At the same time the data is relayed via satellite to the SKF

Condition Monitoring Centre in Luleå or to the Rolls-

Royce Control Centre in Kristinehamn, Sweden.

Alarms are presented as clear text messages to the maintenance crew on board together with additional information showing the condition of different pod components such as; an unbalanced shaft, a bent shaft, cavitations, bearing condition, electrical faults etc.

Satellite Transmissions

The satellite transmissions have two uses: first as a record of the condition of each of the four propulsion pods, and secondly for interpretation by on-shore propulsion pod specialists in case of trouble. The crew on board the QM2 is constantly changing whereas the people on shore are long-term specialists in propulsion pod operation with the necessary skills to fully evalu- ate the data.

Although the role of the on-shore specialists is main- ly advisory they can if required set up special types of measurement remotely in order to troubleshoot.

Normal, satisfactory performance of the pods is indi- cated by reading from sensors, which monitor the level and pattern of vibration, the temperature of motor windings and the bearings, and oil quality including particle content. Vibrations reading are obtained from sensors mounted on the pod bearing housings.

Temperature readings are taken from sensors on the bearing housings and on the motor winding. Oil quali- ty sensors and particle counters are mounted at the lubrication oil sump. One special problem that the

MasCon48 system had to overcome is the pod opera- tional environment. Signals from a pod have to be transmitted using slip rings (slipper rings). However, whenever the ship performs some maneuver, such as increasing speed or changing course, the pod vibration pattern is very different from the normal pattern when cruising. This disturbance of the vibration pattern con- tinues for some time after the maneuver and must be taken into account by the SKF MasCon48 monitoring system.

To do this the system is designed with rule-based diagnostic and a special gating system that checks ships speed, shaft speed, and steering angle before deciding when conditions are stable enough for normal monitoring to be resumed. This provision prevents the saving of unreliable data and the generation of false alarms.

Circle 21 on Reader Service Card 30 Maritime Reporter & Engineering News

Propulsion Technology

Pods make the ship quieter and virtually free of vibra- tion, even at a speed of 30 knots. Queen Mary 2 has four Rolls-Royce Mermaid pods, two fixed and two azimuthing.

A Worldwide Watch on Pod Performance

MR JANUARY2006 #4 (25-32).qxd 1/3/2006 3:32 PM Page 30

29

29

31

31