Page 74: of Maritime Reporter Magazine (June 2011)

Feature: Annual World Yearbook

Read this page in Pdf, Flash or Html5 edition of June 2011 Maritime Reporter Magazine

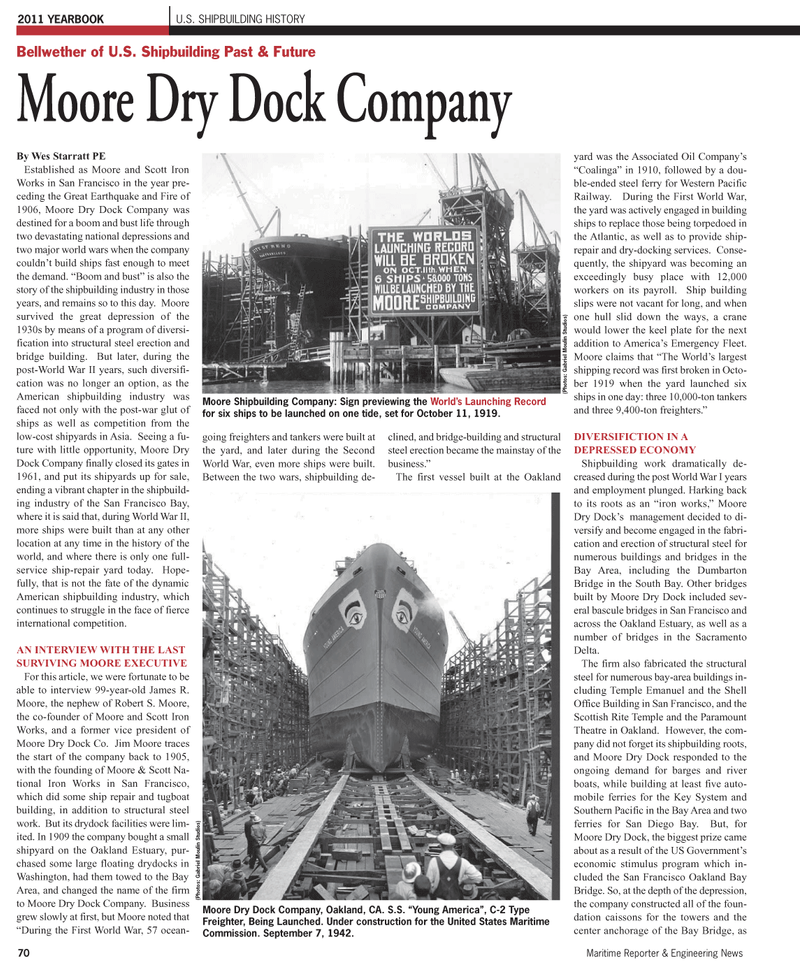

70Maritime Reporter & Engineering News 2011 YEARBOOKU.S. SHIPBUILDING HISTORY By Wes Starratt PE Established as Moore and Scott IronWorks in San Francisco in the year pre- ceding the Great Earthquake and Fire of 1906, Moore Dry Dock Company was destined for a boom and bust life through two devastating national depressions and two major world wars when the company couldnt build ships fast enough to meet the demand. Boom and bust? is also the story of the shipbuilding industry in those years, and remains so to this day. Moore survived the great depression of the 1930s by means of a program of diversi- fication into structural steel erection and bridge building. But later, during the post-World War II years, such diversifi- cation was no longer an option, as the American shipbuilding industry was faced not only with the post-war glut of ships as well as competition from thelow-cost shipyards in Asia. Seeing a fu- ture with little opportunity, Moore Dry Dock Company finally closed its gates in 1961, and put its shipyards up for sale, ending a vibrant chapter in the shipbuild- ing industry of the San Francisco Bay, where it is said that, during World War II, more ships were built than at any other location at any time in the history of the world, and where there is only one full- service ship-repair yard today. Hope- fully, that is not the fate of the dynamic American shipbuilding industry, which continues to struggle in the face of fierce international competition. AN INTERVIEW WITH THE LAST SURVIVING MOORE EXECUTIVE For this article, we were fortunate to be able to interview 99-year-old James R. Moore, the nephew of Robert S. Moore, the co-founder of Moore and Scott IronWorks, and a former vice president of Moore Dry Dock Co. Jim Moore traces the start of the company back to 1905, with the founding of Moore & Scott Na-tional Iron Works in San Francisco, which did some ship repair and tugboatbuilding, in addition to structural steel work. But its drydock facilities were lim- ited. In 1909 the company bought a small shipyard on the Oakland Estuary, pur- chased some large floating drydocks in Washington, had them towed to the Bay Area, and changed the name of the firm to Moore Dry Dock Company. Business grew slowly at first, but Moore noted that During the First World War, 57 ocean- going freighters and tankers were built at the yard, and later during the SecondWorld War, even more ships were built. Between the two wars, shipbuilding de- clined, and bridge-building and structural steel erection became the mainstay of thebusiness.? The first vessel built at the Oakland yard was the Associated Oil Companys Coalinga? in 1910, followed by a dou- ble-ended steel ferry for Western Pacific Railway. During the First World War, the yard was actively engaged in building ships to replace those being torpedoed inthe Atlantic, as well as to provide ship- repair and dry-docking services. Conse-quently, the shipyard was becoming an exceedingly busy place with 12,000 workers on its payroll. Ship building slips were not vacant for long, and when one hull slid down the ways, a crane would lower the keel plate for the next addition to Americas Emergency Fleet. Moore claims that The Worlds largest shipping record was first broken in Octo- ber 1919 when the yard launched sixships in one day: three 10,000-ton tankers and three 9,400-ton freighters.? DIVERSIFICTION IN A DEPRESSED ECONOMYShipbuilding work dramatically de- creased during the post World War I years and employment plunged. Harking back to its roots as an iron works,? Moore Dry Docks management decided to di- versify and become engaged in the fabri- cation and erection of structural steel fornumerous buildings and bridges in the Bay Area, including the Dumbarton Bridge in the South Bay. Other bridges built by Moore Dry Dock included sev- eral bascule bridges in San Francisco andacross the Oakland Estuary, as well as a number of bridges in the SacramentoDelta.The firm also fabricated the structural steel for numerous bay-area buildings in- cluding Temple Emanuel and the Shell Office Building in San Francisco, and the Scottish Rite Temple and the Paramount Theatre in Oakland. However, the com- pany did not forget its shipbuilding roots, and Moore Dry Dock responded to theongoing demand for barges and river boats, while building at least five auto- mobile ferries for the Key System and Southern Pacific in the Bay Area and two ferries for San Diego Bay. But, for Moore Dry Dock, the biggest prize came about as a result of the US Governments economic stimulus program which in-cluded the San Francisco Oakland BayBridge. So, at the depth of the depression,the company constructed all of the foun- dation caissons for the towers and the center anchorage of the Bay Bridge, asBellwether of U.S. Shipbuilding Past & Future Moore Dry Dock Company Moore Dry Dock Company, Oakland, CA. S.S. Young America?, C-2 Type Freighter, Being Launched. Under construction for the United States Maritime Commission. September 7, 1942. (Photos: Gabriel Moulin Studios)Moore Shipbuilding Company: Sign previewing the Worlds Launching Record for six ships to be launched on one tide, set for October 11, 1919. (Photos: Gabriel Moulin Studios)

73

73

75

75