Page 44: of Maritime Reporter Magazine (April 2012)

Offshore Deepwater Annual

Read this page in Pdf, Flash or Html5 edition of April 2012 Maritime Reporter Magazine

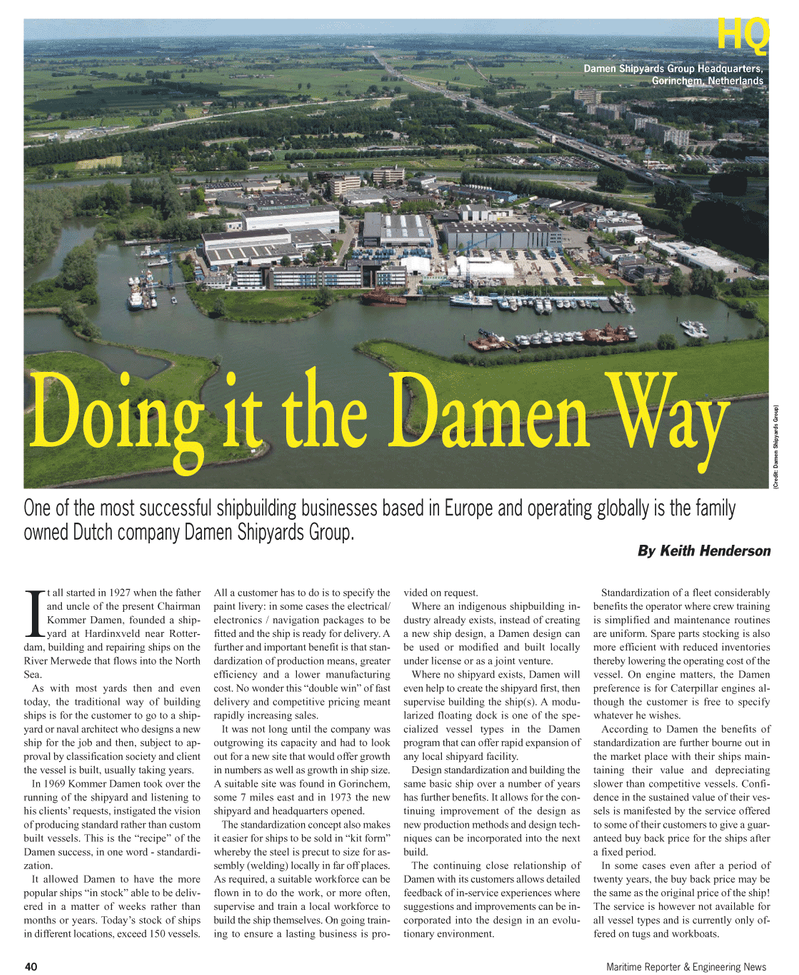

40Maritime Reporter & Engineering News It all started in 1927 when the father and uncle of the present ChairmanKommer Damen, founded a ship- yard at Hardinxveld near Rotter- dam, building and repairing ships on the River Merwede that flows into the North Sea.As with most yards then and even today, the traditional way of building ships is for the customer to go to a ship-yard or naval architect who designs a new ship for the job and then, subject to ap-proval by classification society and client the vessel is built, usually taking years. In 1969 Kommer Damen took over the running of the shipyard and listening to his clients requests, instigated the vision of producing standard rather than custombuilt vessels. This is the recipe? of the Damen success, in one word - standardi- zation. It allowed Damen to have the more popular ships in stock? able to be deliv- ered in a matter of weeks rather thanmonths or years. Todays stock of ships in different locations, exceed 150 vessels. All a customer has to do is to specify thepaint livery: in some cases the electrical/ electronics / navigation packages to be fitted and the ship is ready for delivery. A further and important benefit is that stan- dardization of production means, greaterefficiency and a lower manufacturing cost. No wonder this double win? of fast delivery and competitive pricing meant rapidly increasing sales.It was not long until the company was outgrowing its capacity and had to look out for a new site that would offer growth in numbers as well as growth in ship size. A suitable site was found in Gorinchem, some 7 miles east and in 1973 the new shipyard and headquarters opened. The standardization concept also makes it easier for ships to be sold in kit form?whereby the steel is precut to size for as-sembly (welding) locally in far off places. As required, a suitable workforce can be flown in to do the work, or more often, supervise and train a local workforce to build the ship themselves. On going train- ing to ensure a lasting business is pro- vided on request. Where an indigenous shipbuilding in- dustry already exists, instead of creating a new ship design, a Damen design can be used or modified and built locally under license or as a joint venture. Where no shipyard exists, Damen will even help to create the shipyard first, then supervise building the ship(s). A modu- larized floating dock is one of the spe-cialized vessel types in the Damen program that can offer rapid expansion of any local shipyard facility. Design standardization and building the same basic ship over a number of years has further benefits. It allows for the con- tinuing improvement of the design as new production methods and design tech- niques can be incorporated into the next build. The continuing close relationship ofDamen with its customers allows detailed feedback of in-service experiences where suggestions and improvements can be in- corporated into the design in an evolu- tionary environment. Standardization of a fleet considerablybenefits the operator where crew training is simplified and maintenance routines are uniform. Spare parts stocking is alsomore efficient with reduced inventories thereby lowering the operating cost of the vessel. On engine matters, the Damen preference is for Caterpillar engines al-though the customer is free to specifywhatever he wishes. According to Damen the benefits of standardization are further bourne out inthe market place with their ships main- taining their value and depreciating slower than competitive vessels. Confi- dence in the sustained value of their ves- sels is manifested by the service offered to some of their customers to give a guar- anteed buy back price for the ships after a fixed period. In some cases even after a period of twenty years, the buy back price may be the same as the original price of the ship!The service is however not available for all vessel types and is currently only of- fered on tugs and workboats. Doing it the Damen Way One of the most successful shipbuilding businesses based in Europe and operating globally is the family owned Dutch company Damen Shipyards Group. By Keith Henderson(Credit: Damen Shipyards Group) HQDamen Shipyards Group Headquarters, Gorinchem, Netherlands

43

43

45

45