Page 47: of Maritime Reporter Magazine (December 2012)

Great Ships of 2012

Read this page in Pdf, Flash or Html5 edition of December 2012 Maritime Reporter Magazine

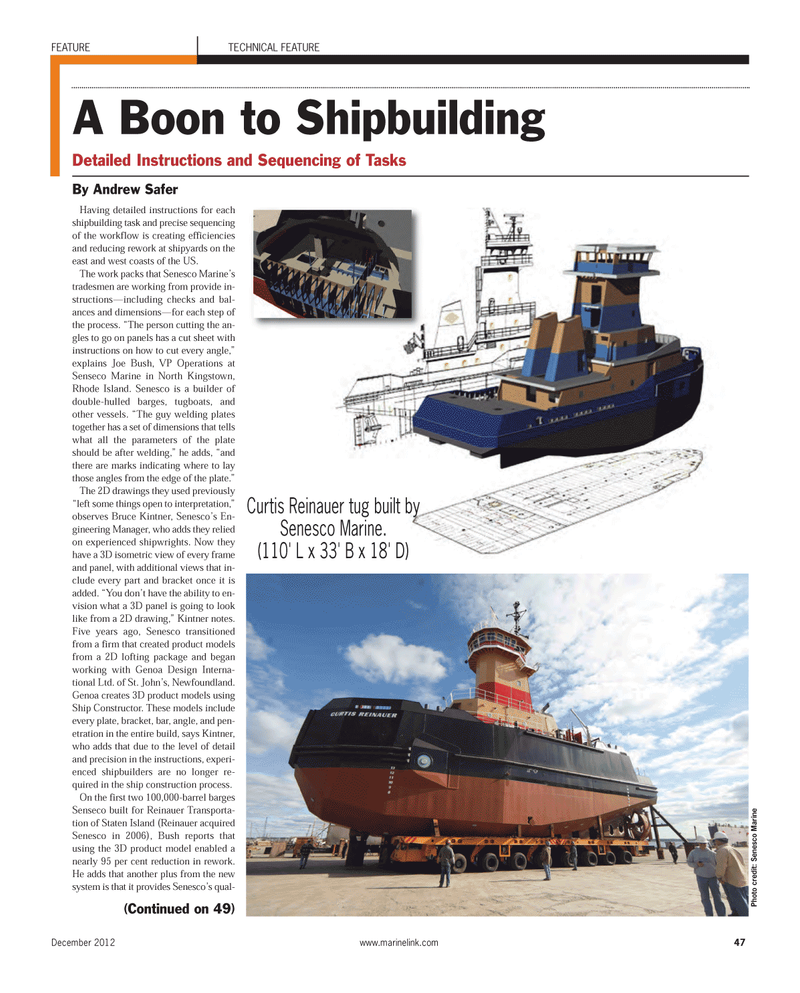

December 2012 www.marinelink.com 47FEATURE TECHNICAL FEATURE Having detailed instructions for each shipbuilding task and precise sequencing of the workflow is creating efficiencies and reducing rework at shipyards on the east and west coasts of the US. The work packs that Senesco Marine?s tradesmen are working from provide in- structions?including checks and bal-ances and dimensions?for each step ofthe process. ?The person cutting the an-gles to go on panels has a cut sheet withinstructions on how to cut every angle,? explains Joe Bush, VP Operations at Senseco Marine in North Kingstown, Rhode Island. Senesco is a builder of double-hulled barges, tugboats, and other vessels. ?The guy welding plates together has a set of dimensions that tellswhat all the parameters of the plateshould be after welding,? he adds, ?and there are marks indicating where to laythose angles from the edge of the plate.? The 2D drawings they used previously ?left some things open to interpretation,? observes Bruce Kintner, Senesco?s En- gineering Manager, who adds they relied on experienced shipwrights. Now they have a 3D isometric view of every frame and panel, with additional views that in- clude every part and bracket once it is added. ?You don?t have the ability to en- vision what a 3D panel is going to looklike from a 2D drawing,? Kintner notes. Five years ago, Senesco transitioned from a firm that created product models from a 2D lofting package and began working with Genoa Design Interna- tional Ltd. of St. John?s, Newfoundland. Genoa creates 3D product models usingShip Constructor. These models include every plate, bracket, bar, angle, and pen- etration in the entire build, says Kintner, who adds that due to the level of detail and precision in the instructions, experi- enced shipbuilders are no longer re- quired in the ship construction process. On the first two 100,000-barrel barges Senseco built for Reinauer Transporta- tion of Staten Island (Reinauer acquiredSenesco in 2006), Bush reports thatusing the 3D product model enabled anearly 95 per cent reduction in rework. He adds that another plus from the new system is that it provides Senesco?s qual- A Boon to ShipbuildingDetailed Instructions and Sequencing of Tasks Photo credit: Senesco Marine Curtis Reinauer tug built by Senesco Marine.(110' L x 33' B x 18' D)By Andrew Safer (Continued on 49)MR#12 (42-49):MR Template 12/4/2012 2:34 PM Page 47

46

46

48

48