Page 10: of Maritime Reporter Magazine (January 2013)

Ship Repair & Conversion

Read this page in Pdf, Flash or Html5 edition of January 2013 Maritime Reporter Magazine

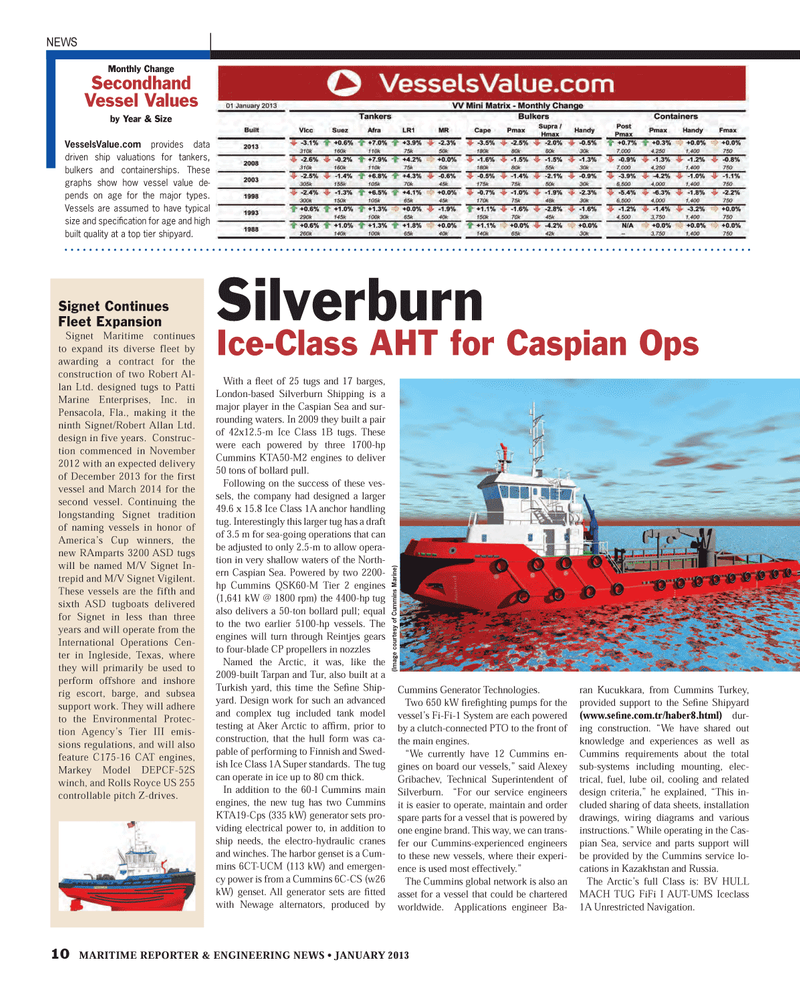

10 MARITIME REPORTER & ENGINEERING NEWS ? JANUARY 2013 NEWSSilverburnIce-Class AHT for Caspian OpsMonthly Change SecondhandVessel Values by Year & Size VesselsValue.com provides data driven ship valuations for tankers, bulkers and containerships. These graphs show how vessel value de-pends on age for the major types. Vessels are assumed to have typical size and speciÞ cation for age and high built quality at a top tier shipyard. Signet Continues Fleet ExpansionSignet Maritime continues to expand its diverse fleet by awarding a contract for the construction of two Robert Al- lan Ltd. designed tugs to Patti Marine Enterprises, Inc. in Pensacola, Fla., making it the ninth Signet/Robert Allan Ltd. design in five years. Construc-tion commenced in November 2012 with an expected delivery of December 2013 for the first vessel and March 2014 for the second vessel. Continuing the longstanding Signet tradition of naming vessels in honor of America?s Cup winners, the new RAmparts 3200 ASD tugs will be named M/V Signet In- trepid and M/V Signet Vigilent. These vessels are the fifth and sixth ASD tugboats delivered for Signet in less than three years and will operate from the International Operations Cen-ter in Ingleside, Texas, where they will primarily be used to perform offshore and inshore rig escort, barge, and subsea support work. They will adhere to the Environmental Protec-tion Agency?s Tier III emis- sions regulations, and will also feature C175-16 CAT engines, Markey Model DEPCF-52S winch, and Rolls Royce US 255 controllable pitch Z-drives. With a ß eet of 25 tugs and 17 barges, London-based Silverburn Shipping is a major player in the Caspian Sea and sur- rounding waters. In 2009 they built a pair of 42x12.5-m Ice Class 1B tugs. These were each powered by three 1700-hp Cummins KTA50-M2 engines to deliver 50 tons of bollard pull. Following on the success of these ves-sels, the company had designed a larger 49.6 x 15.8 Ice Class 1A anchor handling tug. Interestingly this larger tug has a draft of 3.5 m for sea-going operations that can be adjusted to only 2.5-m to allow opera-tion in very shallow waters of the North-ern Caspian Sea. Powered by two 2200-hp Cummins QSK60-M Tier 2 engines (1,641 kW @ 1800 rpm) the 4400-hp tug also delivers a 50-ton bollard pull; equal to the two earlier 5100-hp vessels. The engines will turn through Reintjes gears to four-blade CP propellers in nozzles Named the Arctic, it was, like the 2009-built Tarpan and Tur, also built at a Turkish yard, this time the Se Þ ne Ship- yard. Design work for such an advanced and complex tug included tank model testing at Aker Arctic to af Þ rm, prior to construction, that the hull form was ca-pable of performing to Finnish and Swed-ish Ice Class 1A Super standards. The tug can operate in ice up to 80 cm thick. In addition to the 60-l Cummins main engines, the new tug has two Cummins KTA19-Cps (335 kW) generator sets pro- viding electrical power to, in addition to ship needs, the electro-hydraulic cranes and winches. The harbor genset is a Cum- mins 6CT-UCM (113 kW) and emergen- cy power is from a Cummins 6C-CS (w26 kW) genset. All generator sets are Þ tted with Newage alternators, produced by Cummins Generator Technologies. Two 650 kW Þ reÞ ghting pumps for the vessel?s Fi-Fi-1 System are each powered by a clutch-connected PTO to the front of the main engines. ?We currently have 12 Cummins en- gines on board our vessels,? said Alexey Gribachev, Technical Superintendent of Silverburn. ?For our service engineers it is easier to operate, maintain and order spare parts for a vessel that is powered by one engine brand. This way, we can trans- fer our Cummins-experienced engineers to these new vessels, where their experi-ence is used most effectively.? The Cummins global network is also an asset for a vessel that could be chartered worldwide. Applications engineer Ba- ran Kucukkara, from Cummins Turkey, provided support to the SeÞ ne Shipyard (www.se Þ ne.com.tr/haber8.html) dur- ing construction. ?We have shared out knowledge and experiences as well as Cummins requirements about the total sub-systems including mounting, elec-trical, fuel, lube oil, cooling and related design criteria,? he explained, ?This in-cluded sharing of data sheets, installation drawings, wiring diagrams and various instructions.? While operating in the Cas- pian Sea, service and parts support will be provided by the Cummins service lo-cations in Kazakhstan and Russia. The Arctic?s full Class is: BV HULL MACH TUG FiFi I AUT-UMS Iceclass 1A Unrestricted Navigation. (Image courtesy of Cummins Marine) MR #1 (10-17).indd 10MR #1 (10-17).indd 101/3/2013 11:54:04 AM1/3/2013 11:54:04 AM

9

9

11

11