Page 77: of Maritime Reporter Magazine (August 2013)

Shipyard Edition

Read this page in Pdf, Flash or Html5 edition of August 2013 Maritime Reporter Magazine

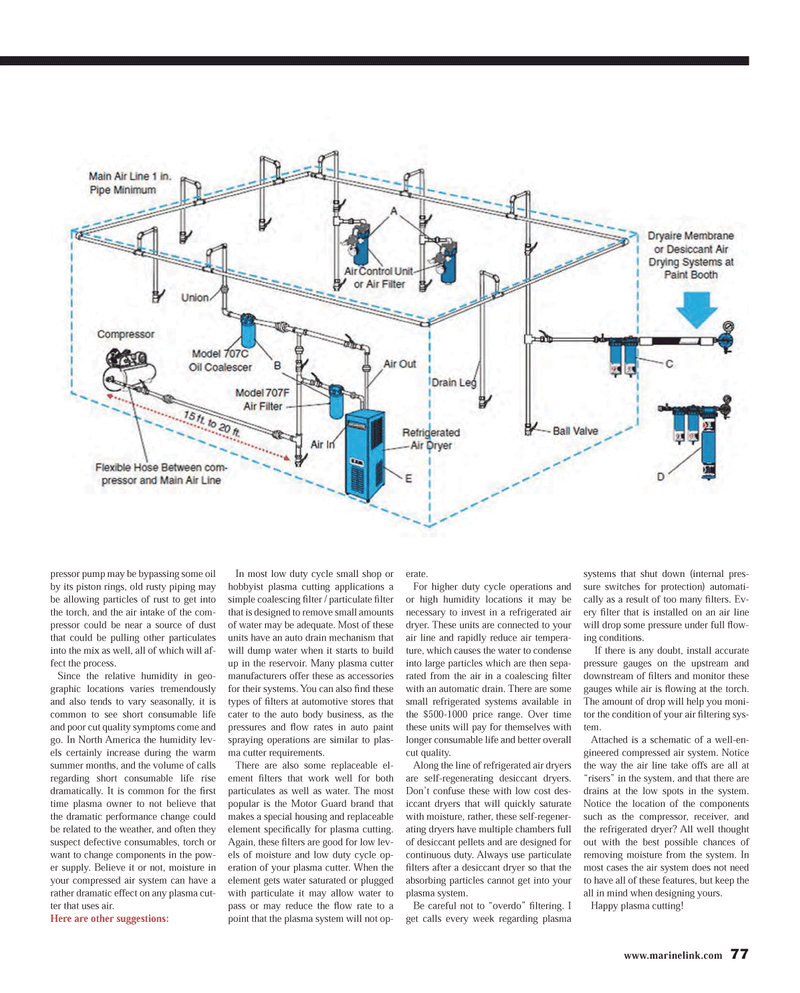

www.marinelink.com 77pressor pump may be bypassing some oil by its piston rings, old rusty piping may be allowing particles of rust to get into the torch, and the air intake of the com-pressor could be near a source of dust that could be pulling other particulates into the mix as well, all of which will af-fect the process. Since the relative humidity in geo-graphic locations varies tremendously and also tends to vary seasonally, it is common to see short consumable life and poor cut quality symptoms come and go. In North America the humidity lev- els certainly increase during the warm summer months, and the volume of calls regarding short consumable life rise dramatically. It is common for the Þ rst time plasma owner to not believe that the dramatic performance change could be related to the weather, and often they suspect defective consumables, torch or want to change components in the pow-er supply. Believe it or not, moisture in your compressed air system can have a rather dramatic effect on any plasma cut- ter that uses air. Here are other suggestions: In most low duty cycle small shop or hobbyist plasma cutting applications a simple coalescing Þ lter / particulate Þ lter that is designed to remove small amounts of water may be adequate. Most of these units have an auto drain mechanism that will dump water when it starts to build up in the reservoir. Many plasma cutter manufacturers offer these as accessories for their systems. You can also Þ nd these types of Þ lters at automotive stores that cater to the auto body business, as the pressures and ß ow rates in auto paint spraying operations are similar to plas-ma cutter requirements.There are also some replaceable el-ement Þ lters that work well for both particulates as well as water. The most popular is the Motor Guard brand that makes a special housing and replaceable element speciÞ cally for plasma cutting. Again, these Þ lters are good for low lev- els of moisture and low duty cycle op-eration of your plasma cutter. When the element gets water saturated or plugged with particulate it may allow water to pass or may reduce the ß ow rate to a point that the plasma system will not op-erate.For higher duty cycle operations and or high humidity locations it may be necessary to invest in a refrigerated air dryer. These units are connected to your air line and rapidly reduce air tempera-ture, which causes the water to condense into large particles which are then sepa- rated from the air in a coalescing Þ lter with an automatic drain. There are some small refrigerated systems available in the $500-1000 price range. Over time these units will pay for themselves with longer consumable life and better overall cut quality. Along the line of refrigerated air dryers are self-regenerating desiccant dryers. Don?t confuse these with low cost des- iccant dryers that will quickly saturate with moisture, rather, these self-regener- ating dryers have multiple chambers full of desiccant pellets and are designed for continuous duty. Always use particulate Þ lters after a desiccant dryer so that the absorbing particles cannot get into your plasma system. Be careful not to ?overdo? Þ ltering. I get calls every week regarding plasma systems that shut down (internal pres-sure switches for protection) automati-cally as a result of too many Þ lters. Ev- ery Þ lter that is installed on an air line will drop some pressure under full ß ow-ing conditions. If there is any doubt, install accurate pressure gauges on the upstream and downstream of Þ lters and monitor these gauges while air is ß owing at the torch. The amount of drop will help you moni-tor the condition of your air Þ ltering sys- tem.Attached is a schematic of a well-en-gineered compressed air system. Notice the way the air line take offs are all at ?risers? in the system, and that there are drains at the low spots in the system. Notice the location of the components such as the compressor, receiver, and the refrigerated dryer? All well thought out with the best possible chances of removing moisture from the system. In most cases the air system does not need to have all of these features, but keep the all in mind when designing yours.Happy plasma cutting! MR #8 (74-82).indd 77MR #8 (74-82).indd 778/2/2013 9:16:20 AM8/2/2013 9:16:20 AM

76

76

78

78