Page 16: of Maritime Reporter Magazine (May 2015)

The Marine Propulsion Edition

Read this page in Pdf, Flash or Html5 edition of May 2015 Maritime Reporter Magazine

PROPULSION EFFICIENCY BY DESIGN

Numerical Towing Tanks

A practical reality?

BY STEPHEN FERGUSON, CD-ADAPCO ince the ? rst commercial ship ing data that could be used to in? uence basin was commissioned in and improve the design. CFD also car- 1883, towing tanks have pro- ries the distinct advantage of result ac-

Svided naval architects with a curacy independent of the scale at which

Challenge 1 reliable method of predicting the perfor- they are calculated.

mance of a ship at sea. Towing tanks are However, up until recently, that pros-

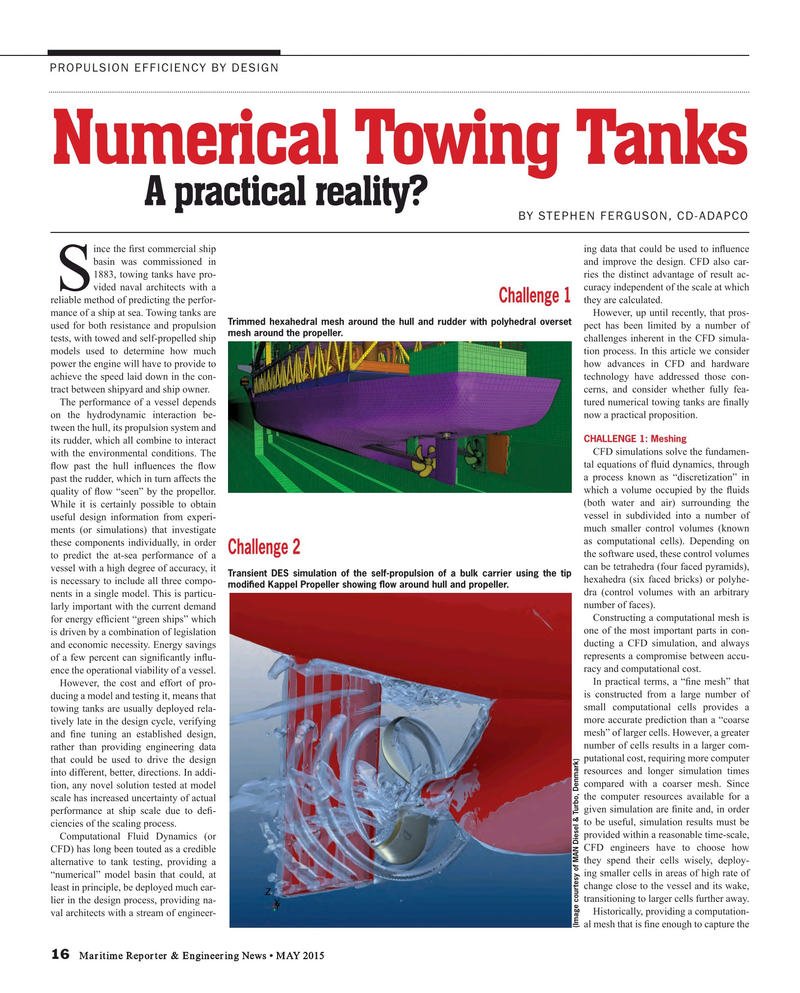

Trimmed hexahedral mesh around the hull and rudder with polyhedral overset used for both resistance and propulsion pect has been limited by a number of mesh around the propeller.

tests, with towed and self-propelled ship challenges inherent in the CFD simula- models used to determine how much tion process. In this article we consider power the engine will have to provide to how advances in CFD and hardware achieve the speed laid down in the con- technology have addressed those con- tract between shipyard and ship owner. cerns, and consider whether fully fea-

The performance of a vessel depends tured numerical towing tanks are ? nally on the hydrodynamic interaction be- now a practical proposition.

tween the hull, its propulsion system and

CHALLENGE 1: Meshing its rudder, which all combine to interact

CFD simulations solve the fundamen- with the environmental conditions. The tal equations of ? uid dynamics, through ? ow past the hull in? uences the ? ow a process known as “discretization” in past the rudder, which in turn affects the which a volume occupied by the ? uids quality of ? ow “seen” by the propellor. (both water and air) surrounding the

While it is certainly possible to obtain vessel in subdivided into a number of useful design information from experi- much smaller control volumes (known ments (or simulations) that investigate as computational cells). Depending on these components individually, in order

Challenge 2 the software used, these control volumes to predict the at-sea performance of a can be tetrahedra (four faced pyramids), vessel with a high degree of accuracy, it

Transient DES simulation of the self-propulsion of a bulk carrier using the tip hexahedra (six faced bricks) or polyhe- is necessary to include all three compo- modi? ed Kappel Propeller showing ? ow around hull and propeller.

dra (control volumes with an arbitrary nents in a single model. This is particu- number of faces).

larly important with the current demand

Constructing a computational mesh is for energy ef? cient “green ships” which one of the most important parts in con- is driven by a combination of legislation ducting a CFD simulation, and always and economic necessity. Energy savings represents a compromise between accu- of a few percent can signi? cantly in? u- racy and computational cost. ence the operational viability of a vessel.

In practical terms, a “? ne mesh” that

However, the cost and effort of pro- is constructed from a large number of ducing a model and testing it, means that small computational cells provides a towing tanks are usually deployed rela- more accurate prediction than a “coarse tively late in the design cycle, verifying mesh” of larger cells. However, a greater and ? ne tuning an established design, number of cells results in a larger com- rather than providing engineering data putational cost, requiring more computer that could be used to drive the design resources and longer simulation times into different, better, directions. In addi- compared with a coarser mesh. Since tion, any novel solution tested at model the computer resources available for a scale has increased uncertainty of actual given simulation are ? nite and, in order performance at ship scale due to de? - to be useful, simulation results must be ciencies of the scaling process.

provided within a reasonable time-scale,

Computational Fluid Dynamics (or

CFD engineers have to choose how

CFD) has long been touted as a credible they spend their cells wisely, deploy- alternative to tank testing, providing a ing smaller cells in areas of high rate of “numerical” model basin that could, at change close to the vessel and its wake, least in principle, be deployed much ear- transitioning to larger cells further away.

lier in the design process, providing na-

Historically, providing a computation- val architects with a stream of engineer- al mesh that is ? ne enough to capture the (Image courtesy of MAN Diesel & Turbo, Denmark) 16 Maritime Reporter & Engineering News • MAY 2015

MR #5 (10-17).indd 16 MR #5 (10-17).indd 16 4/30/2015 10:11:52 AM4/30/2015 10:11:52 AM

15

15

17

17