Page 8: of Maritime Reporter Magazine (June 2015)

Annual World Yearbook

Read this page in Pdf, Flash or Html5 edition of June 2015 Maritime Reporter Magazine

TECH FILE

Van Oord Develops Van Oord Develops

Deep Deep

Excavation Excavation

SystemSystem

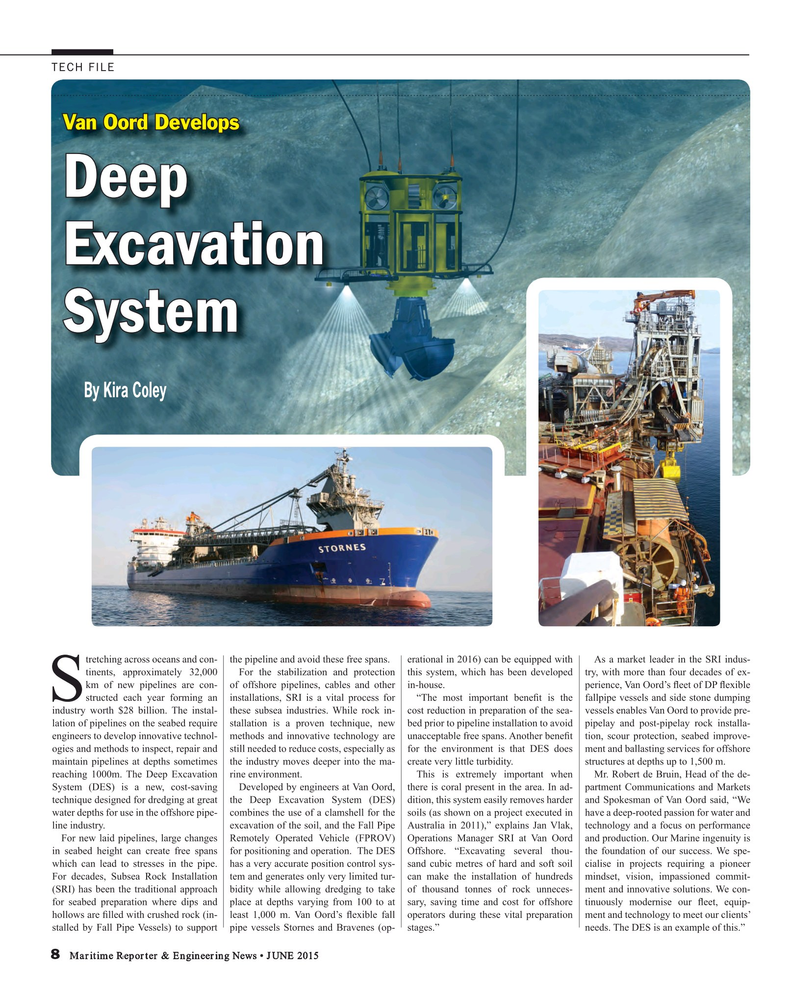

By Kira Coley tretching across oceans and con- the pipeline and avoid these free spans. erational in 2016) can be equipped with As a market leader in the SRI indus- tinents, approximately 32,000 For the stabilization and protection this system, which has been developed try, with more than four decades of ex- km of new pipelines are con- of offshore pipelines, cables and other in-house. perience, Van Oord’s ? eet of DP ? exible

Sstructed each year forming an installations, SRI is a vital process for “The most important bene? t is the fallpipe vessels and side stone dumping industry worth $28 billion. The instal- these subsea industries. While rock in- cost reduction in preparation of the sea- vessels enables Van Oord to provide pre- lation of pipelines on the seabed require stallation is a proven technique, new bed prior to pipeline installation to avoid pipelay and post-pipelay rock installa- engineers to develop innovative technol- methods and innovative technology are unacceptable free spans. Another bene? t tion, scour protection, seabed improve- ogies and methods to inspect, repair and still needed to reduce costs, especially as for the environment is that DES does ment and ballasting services for offshore maintain pipelines at depths sometimes the industry moves deeper into the ma- create very little turbidity. structures at depths up to 1,500 m. reaching 1000m. The Deep Excavation rine environment. This is extremely important when Mr. Robert de Bruin, Head of the de-

System (DES) is a new, cost-saving Developed by engineers at Van Oord, there is coral present in the area. In ad- partment Communications and Markets technique designed for dredging at great the Deep Excavation System (DES) dition, this system easily removes harder and Spokesman of Van Oord said, “We water depths for use in the offshore pipe- combines the use of a clamshell for the soils (as shown on a project executed in have a deep-rooted passion for water and line industry. excavation of the soil, and the Fall Pipe Australia in 2011),” explains Jan Vlak, technology and a focus on performance

For new laid pipelines, large changes Remotely Operated Vehicle (FPROV) Operations Manager SRI at Van Oord and production. Our Marine ingenuity is in seabed height can create free spans for positioning and operation. The DES Offshore. “Excavating several thou- the foundation of our success. We spe- which can lead to stresses in the pipe. has a very accurate position control sys- sand cubic metres of hard and soft soil cialise in projects requiring a pioneer

For decades, Subsea Rock Installation tem and generates only very limited tur- can make the installation of hundreds mindset, vision, impassioned commit- (SRI) has been the traditional approach bidity while allowing dredging to take of thousand tonnes of rock unneces- ment and innovative solutions. We con- for seabed preparation where dips and place at depths varying from 100 to at sary, saving time and cost for offshore tinuously modernise our ? eet, equip- hollows are ? lled with crushed rock (in- least 1,000 m. Van Oord’s ? exible fall operators during these vital preparation ment and technology to meet our clients’ stalled by Fall Pipe Vessels) to support pipe vessels Stornes and Bravenes (op- stages.” needs. The DES is an example of this.” 8 Maritime Reporter & Engineering News • JUNE 2015

MR #6 (1-9).indd 8 MR #6 (1-9).indd 8 6/9/2015 10:47:46 AM6/9/2015 10:47:46 AM

7

7

9

9