Page 29: of Maritime Reporter Magazine (August 2015)

Shipyard Edition

Read this page in Pdf, Flash or Html5 edition of August 2015 Maritime Reporter Magazine

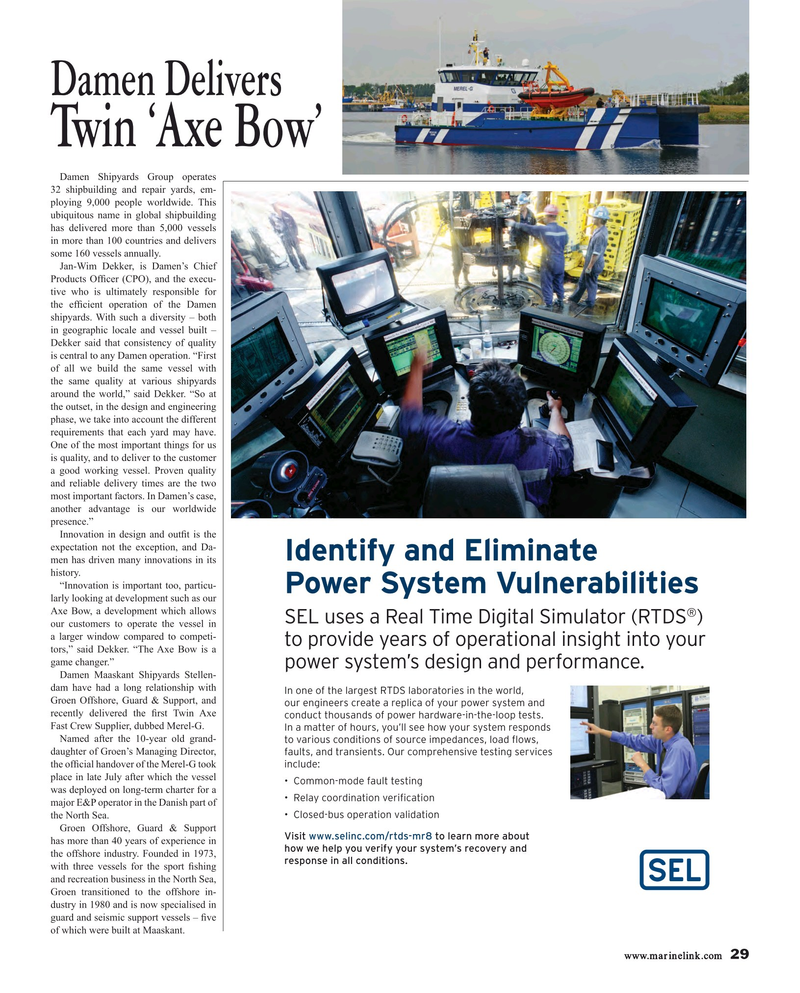

Damen Delivers

Twin ‘Axe Bow’

Damen Shipyards Group operates 32 shipbuilding and repair yards, em- ploying 9,000 people worldwide. This ubiquitous name in global shipbuilding has delivered more than 5,000 vessels in more than 100 countries and delivers some 160 vessels annually.

Jan-Wim Dekker, is Damen’s Chief

Products Of? cer (CPO), and the execu- tive who is ultimately responsible for the ef? cient operation of the Damen shipyards. With such a diversity – both in geographic locale and vessel built –

Dekker said that consistency of quality is central to any Damen operation. “First of all we build the same vessel with the same quality at various shipyards around the world,” said Dekker. “So at the outset, in the design and engineering phase, we take into account the different requirements that each yard may have.

One of the most important things for us is quality, and to deliver to the customer a good working vessel. Proven quality and reliable delivery times are the two most important factors. In Damen’s case, another advantage is our worldwide presence.”

Innovation in design and out? t is the expectation not the exception, and Da-

Identify and Eliminate men has driven many innovations in its history.

“Innovation is important too, particu-

Power System Vulnerabilities larly looking at development such as our

Axe Bow, a development which allows ®

SEL uses a Real Time Digital Simulator (RTDS ) our customers to operate the vessel in a larger window compared to competi- to provide years of operational insight into your tors,” said Dekker. “The Axe Bow is a game changer.” power system’s design and performance.

Damen Maaskant Shipyards Stellen- dam have had a long relationship with

In one of the largest RTDS laboratories in the world,

Groen Offshore, Guard & Support, and our engineers create a replica of your power system and recently delivered the ? rst Twin Axe conduct thousands of power hardware-in-the-loop tests.

Fast Crew Supplier, dubbed Merel-G.

In a matter of hours, you’ll see how your system responds

Named after the 10-year old grand- to various conditions of source impedances, load ?ows, daughter of Groen’s Managing Director, faults, and transients. Our comprehensive testing services the of? cial handover of the Merel-G took include: place in late July after which the vessel • Common-mode fault testing was deployed on long-term charter for a • Relay coordination veri?cation major E&P operator in the Danish part of the North Sea. • Closed-bus operation validation

Groen Offshore, Guard & Support

Visit www.selinc.com/rtds-mr8 to learn more about has more than 40 years of experience in how we help you verify your system’s recovery and the offshore industry. Founded in 1973, response in all conditions.

with three vessels for the sport ? shing and recreation business in the North Sea,

Groen transitioned to the offshore in- dustry in 1980 and is now specialised in guard and seismic support vessels – ? ve of which were built at Maaskant. www.marinelink.com 29

MR #8 (26-33).indd 29 MR #8 (26-33).indd 29 8/10/2015 1:02:32 PM8/10/2015 1:02:32 PM

28

28

30

30