Page 18: of Maritime Reporter Magazine (October 2015)

Marine Design Annual

Read this page in Pdf, Flash or Html5 edition of October 2015 Maritime Reporter Magazine

EYE ON DESIGN

Deep water

Complex Hull Shapes Require

Sophisticated

Shallow Water

Assessment

Van Oord asked MARIN to perform a full assessment of the hull lines of its new hopper dredger.

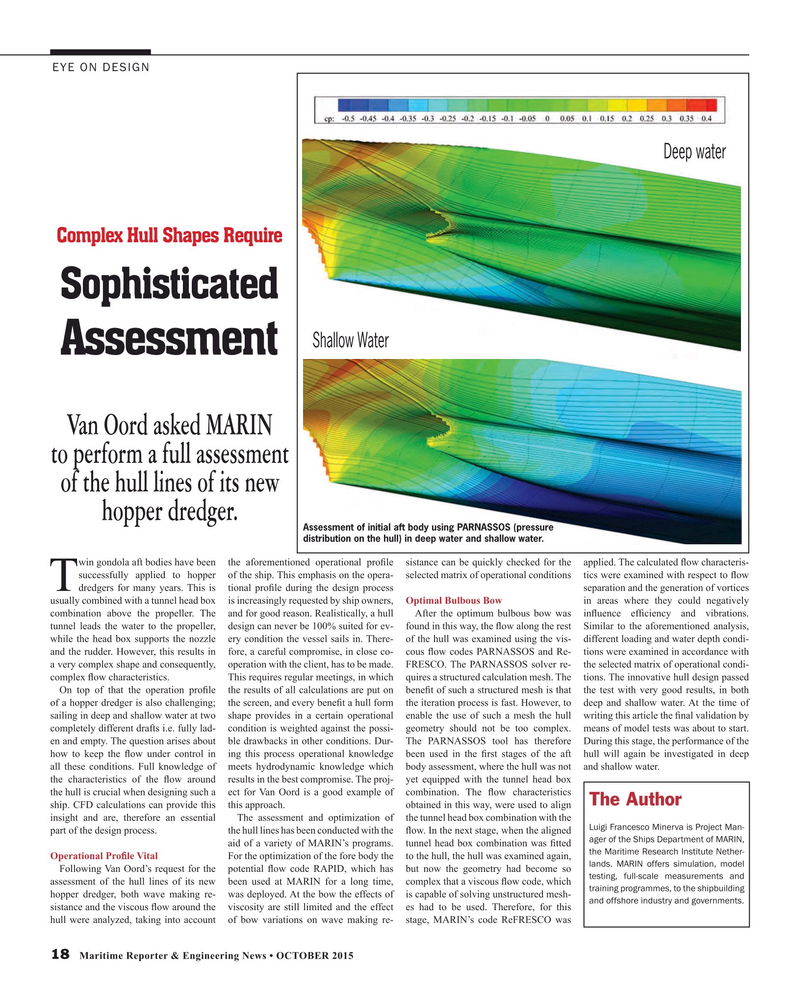

Assessment of initial aft body using PARNASSOS (pressure distribution on the hull) in deep water and shallow water.

win gondola aft bodies have been the aforementioned operational pro? le sistance can be quickly checked for the applied. The calculated ? ow characteris- successfully applied to hopper of the ship. This emphasis on the opera- selected matrix of operational conditions tics were examined with respect to ? ow

T dredgers for many years. This is tional pro? le during the design process separation and the generation of vortices usually combined with a tunnel head box is increasingly requested by ship owners, Optimal Bulbous Bow in areas where they could negatively combination above the propeller. The and for good reason. Realistically, a hull After the optimum bulbous bow was in? uence ef? ciency and vibrations. tunnel leads the water to the propeller, design can never be 100% suited for ev- found in this way, the ? ow along the rest Similar to the aforementioned analysis, while the head box supports the nozzle ery condition the vessel sails in. There- of the hull was examined using the vis- different loading and water depth condi- and the rudder. However, this results in fore, a careful compromise, in close co- cous ? ow codes PARNASSOS and Re- tions were examined in accordance with a very complex shape and consequently, operation with the client, has to be made. FRESCO. The PARNASSOS solver re- the selected matrix of operational condi- complex ? ow characteristics. This requires regular meetings, in which quires a structured calculation mesh. The tions. The innovative hull design passed

On top of that the operation pro? le the results of all calculations are put on bene? t of such a structured mesh is that the test with very good results, in both of a hopper dredger is also challenging; the screen, and every bene? t a hull form the iteration process is fast. However, to deep and shallow water. At the time of sailing in deep and shallow water at two shape provides in a certain operational enable the use of such a mesh the hull writing this article the ? nal validation by completely different drafts i.e. fully lad- condition is weighted against the possi- geometry should not be too complex. means of model tests was about to start. en and empty. The question arises about ble drawbacks in other conditions. Dur- The PARNASSOS tool has therefore During this stage, the performance of the how to keep the ? ow under control in ing this process operational knowledge been used in the ? rst stages of the aft hull will again be investigated in deep all these conditions. Full knowledge of meets hydrodynamic knowledge which body assessment, where the hull was not and shallow water.

the characteristics of the ? ow around results in the best compromise. The proj- yet equipped with the tunnel head box the hull is crucial when designing such a ect for Van Oord is a good example of combination. The ? ow characteristics

The Author ship. CFD calculations can provide this this approach. obtained in this way, were used to align insight and are, therefore an essential The assessment and optimization of the tunnel head box combination with the

Luigi Francesco Minerva is Project Man- part of the design process. the hull lines has been conducted with the ? ow. In the next stage, when the aligned ager of the Ships Department of MARIN, aid of a variety of MARIN’s programs. tunnel head box combination was ? tted the Maritime Research Institute Nether-

Operational Pro? le Vital For the optimization of the fore body the to the hull, the hull was examined again, lands. MARIN offers simulation, model

Following Van Oord’s request for the potential ? ow code RAPID, which has but now the geometry had become so testing, full-scale measurements and assessment of the hull lines of its new been used at MARIN for a long time, complex that a viscous ? ow code, which training programmes, to the shipbuilding hopper dredger, both wave making re- was deployed. At the bow the effects of is capable of solving unstructured mesh- and offshore industry and governments.

sistance and the viscous ? ow around the viscosity are still limited and the effect es had to be used. Therefore, for this hull were analyzed, taking into account of bow variations on wave making re- stage, MARIN’s code ReFRESCO was 18 Maritime Reporter & Engineering News • OCTOBER 2015

MR #10 (18-25).indd 18 10/2/2015 2:53:40 PM

17

17

19

19