Page 65: of Maritime Reporter Magazine (March 2017)

U.S. Navy Quarterly & Maritime Simulation Technologies

Read this page in Pdf, Flash or Html5 edition of March 2017 Maritime Reporter Magazine

BALLAST WATER TECHNOLOGY ADVERTORIAL

AUTOMATIC SELF-CLEANING SCREEN FILTERS FOR BALLAST WATER FILTRATION

Forsta shipboard & ballast water ? lters effectively re- equipment lifespan. long the seawater life of stainless components, making move particles and seawater debris from ballast water Housings are constructed from Fiberglass Reinforced 316L & 904 stainless viable options in certain scenarios. and other shipboard water lines. The ? ltration system is Plastic (FRP), with screens and all wetted components On ships with existing infrastructure, the performance fully automated and does not cause an interruption to of Forsta’s ballast water ? lters constructed from seawa- history of the materials onboard is often the most use- ? ow during the short cleaning cycle. Forsta self-cleaning ter- resistant plastic or other high alloy materials. Forsta ful indicator of how to select materials moving forward. ? lters for ballast water will easily integrate into a com- ballast water ? lters are made to exceed PREN 40+ re- Forsta engineers analyze how materials have held up to plete ballast water management system (BWMS). quirements for the harshest of environments. their conditions as a way to best inform a retro? t.

Forsta ballast water ? lters remove large, hazardous or- Forsta takes a long-term and sustainable approach This methodology has been effectively utilized in the ganisms as well as sediment (down to 40 micron) before to the design of ? lters for corrosive environments. In design of equipment for saline lakebeds, shipboard re- water enters the main disinfection treatment. Particle shipboard applications such as Ballast Water Treatment, verse osmosis desalination, plant desalination, and pro- removal ef? ciency above 40 micron is 98-100% with up Forsta sees it as an imperative to minimize the mainte- duced water. Piping and other appurtenances provide to 50% additional particle reduction below 40 micron nance requirements. an excellent road map from which to introduce new (due to the ? lter cake effect). Where conditions allow (i.e. in colder temperatures, equipment. If pitting, rust, or holes have plagued a 316 Forsta ballast water ? lter housings are available in high lower chlorides), material selection may be modi? ed to element, for example, it provides evidence for the need grade materials for maximum corrosion resistance, re- include a variety of additional alloys. Surface ? nishes of a material upgrade. ducing the need for replacement parts and improving such as pickle passivation\ & electro-polishing can pro-

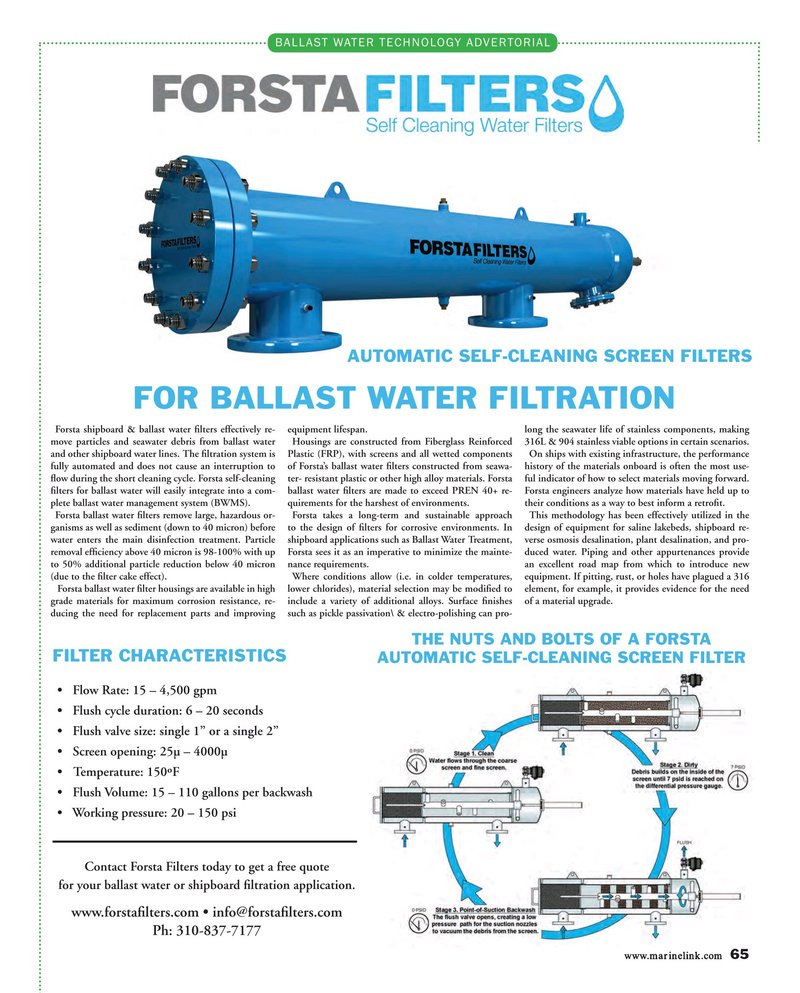

THE NUTS AND BOLTS OF A FORSTA

FILTER CHARACTERISTICS

AUTOMATIC SELF-CLEANING SCREEN FILTER • Flow Rate: 15 – 4,500 gpm • Flush cycle duration: 6 – 20 seconds • Flush valve size: single 1” or a single 2” • Screen opening: 25µ – 4000µ • Temperature: 150ºF • Flush Volume: 15 – 110 gallons per backwash • Working pressure: 20 – 150 psi

Contact Forsta Filters today to get a free quote for your ballast water or shipboard ? ltration application. www.forsta? lters.com • info@forsta? lters.com

Ph: 310-837-7177 www.marinelink.com 65

MR #3 (58-65).indd 65 MR #3 (58-65).indd 65 3/6/2017 2:48:30 PM3/6/2017 2:48:30 PM

64

64

66

66