Page 44: of Maritime Reporter Magazine (September 2018)

Maritime Port & Ship Security

Read this page in Pdf, Flash or Html5 edition of September 2018 Maritime Reporter Magazine

WELDING TECHNOLOGY

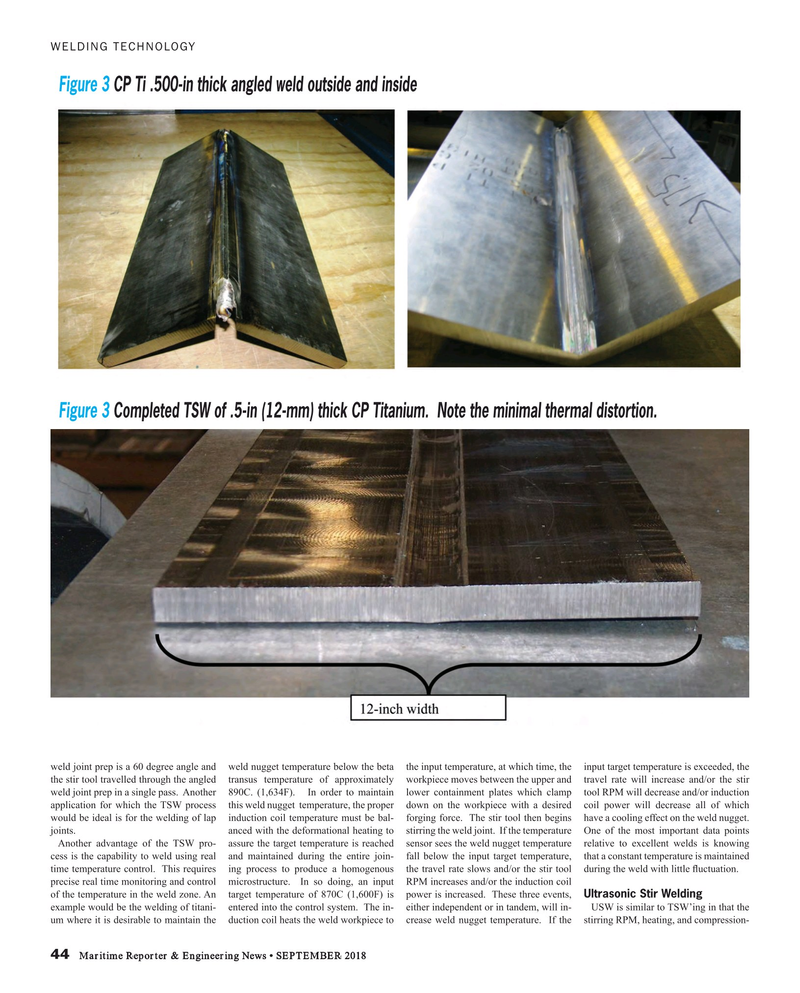

Figure 3 CP Ti .500-in thick angled weld outside and inside

Figure 3 Completed TSW of .5-in (12-mm) thick CP Titanium. Note the minimal thermal distortion.

weld joint prep is a 60 degree angle and weld nugget temperature below the beta the input temperature, at which time, the input target temperature is exceeded, the the stir tool travelled through the angled transus temperature of approximately workpiece moves between the upper and travel rate will increase and/or the stir weld joint prep in a single pass. Another 890C. (1,634F). In order to maintain lower containment plates which clamp tool RPM will decrease and/or induction application for which the TSW process this weld nugget temperature, the proper down on the workpiece with a desired coil power will decrease all of which would be ideal is for the welding of lap induction coil temperature must be bal- forging force. The stir tool then begins have a cooling effect on the weld nugget. joints. anced with the deformational heating to stirring the weld joint. If the temperature One of the most important data points

Another advantage of the TSW pro- assure the target temperature is reached sensor sees the weld nugget temperature relative to excellent welds is knowing cess is the capability to weld using real and maintained during the entire join- fall below the input target temperature, that a constant temperature is maintained time temperature control. This requires ing process to produce a homogenous the travel rate slows and/or the stir tool during the weld with little ? uctuation. precise real time monitoring and control microstructure. In so doing, an input RPM increases and/or the induction coil

Ultrasonic Stir Welding of the temperature in the weld zone. An target temperature of 870C (1,600F) is power is increased. These three events, example would be the welding of titani- entered into the control system. The in- either independent or in tandem, will in- USW is similar to TSW’ing in that the um where it is desirable to maintain the duction coil heats the weld workpiece to crease weld nugget temperature. If the stirring RPM, heating, and compression- 44 Maritime Reporter & Engineering News • SEPTEMBER 2018

MR #9 (42-49).indd 44 MR #9 (42-49).indd 44 9/5/2018 11:49:43 AM9/5/2018 11:49:43 AM

43

43

45

45