Page 81: of Maritime Reporter Magazine (October 2018)

Marine Design Annual

Read this page in Pdf, Flash or Html5 edition of October 2018 Maritime Reporter Magazine

COATINGS & CORROSION CONTROL

Poly? ake Coatings

Protection against chemical, mechanical and galvanic corrosion. By Lisa Overing

Corrosion starts from the inside out. The alkali that metallurgical tests and it was all 5083, 5086 good discharge line to protect the carbon steel piping with neutralizes acid water - and the acid water produced quality pipe, just as speci? ed on the drawings. It was a consistent reduction of coat in respect to exotics in a gas scrubbing system - are corrosive. Contain- veri? ed good stuff, but prone to breaking down un- alloys. ment surfaces resistant to both alkali, acid water and der a certain temperature.” Lucignani said applying Poly? ake coat to diffus- their combination provide a safer ship with less ex- Capt. Sache needed to replace the large engine ers and overboard discharge pipes for gas scrubbers pensive maintenance. dump, port and starboard, dividing the wet exhaust systems protects hull corrosion from the acid plume

While selecting metal alloys as more resistant to from dry exhaust dumps. He considered installing formed during load transfer, citing several cruise either acid or to alkali, facing all conditions simul- straight pipe, but began pondering coatings. lines, Celebrity and Grimaldi amongst success sto- taneously is problematic, as temperature plays an “This is not ceramic that lifts and keeps peeling,” ries. important role in pitting corrosion. said Capt. Sachse, adding “Poly? ake is more like a A critical phase to the success of Poly? ake coating

Ultimately, leaking occurs within weeks, produc- plastic tube, plastic coating. I ? gure what can it hurt? is proper primer with an abrasive pro? le; a rough ing a hazardous, corrosive ? uid compromising any It’s described as a ? ve-year product with a 20-year grind allows the base product to bite on. High volt- equipment with a contact surface as well as exposed life. It has been used extensively in the commercial age instruments test for minimal porosity on the personnel. market throughout Europe. Joerg Scheele of e4P- coating.

Leakage repair is expensive with potential collat- ower and Poly? ake has hands on knowledge as an One unique property of Poly? ake, according to eral damage, insomuch as yard repair sessions can engineer at sea. He has seen ships fail and rebuilt Capt. Sachse, is Poly? ake has the same coef? cient quickly spin into a re? t gone rogue. systems to prevent subsequent failure. I have total of expansion as the aluminum. “It could be the same

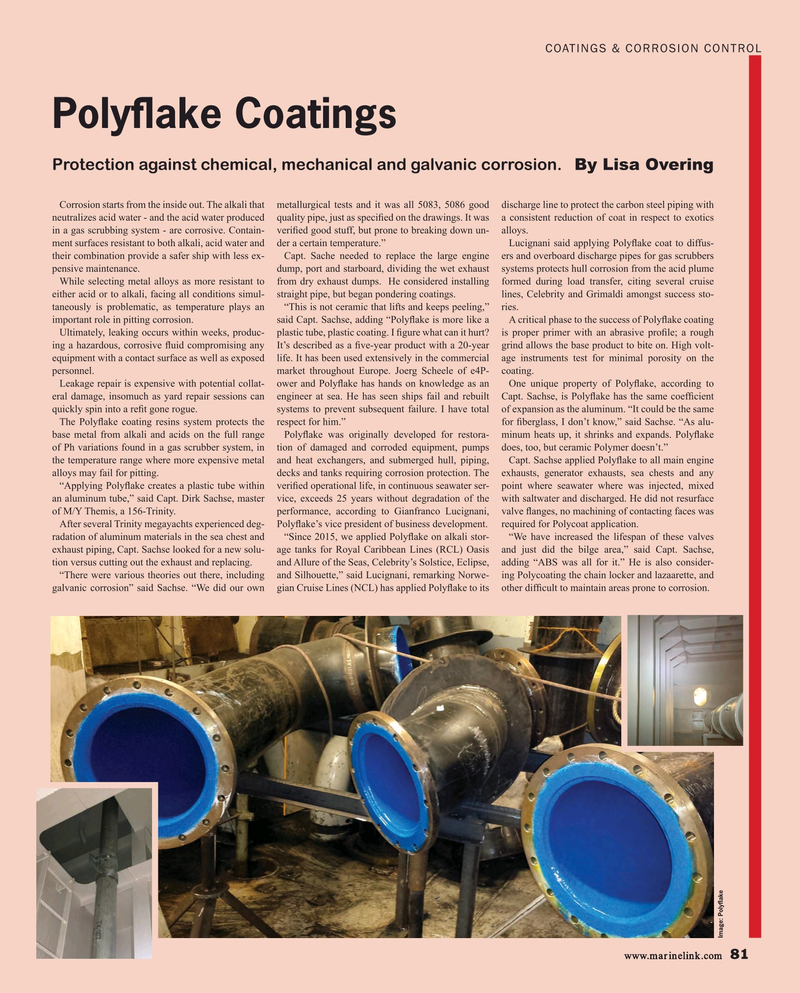

The Poly? ake coating resins system protects the respect for him.” for ? berglass, I don’t know,” said Sachse. “As alu- base metal from alkali and acids on the full range Poly? ake was originally developed for restora- minum heats up, it shrinks and expands. Poly? ake of Ph variations found in a gas scrubber system, in tion of damaged and corroded equipment, pumps does, too, but ceramic Polymer doesn’t.” the temperature range where more expensive metal and heat exchangers, and submerged hull, piping, Capt. Sachse applied Poly? ake to all main engine alloys may fail for pitting. decks and tanks requiring corrosion protection. The exhausts, generator exhausts, sea chests and any “Applying Poly? ake creates a plastic tube within veri? ed operational life, in continuous seawater ser- point where seawater where was injected, mixed an aluminum tube,” said Capt. Dirk Sachse, master vice, exceeds 25 years without degradation of the with saltwater and discharged. He did not resurface of M/Y Themis, a 156-Trinity. performance, according to Gianfranco Lucignani, valve ? anges, no machining of contacting faces was

After several Trinity megayachts experienced deg- Poly? ake’s vice president of business development. required for Polycoat application. radation of aluminum materials in the sea chest and “Since 2015, we applied Poly? ake on alkali stor- “We have increased the lifespan of these valves exhaust piping, Capt. Sachse looked for a new solu- age tanks for Royal Caribbean Lines (RCL) Oasis and just did the bilge area,” said Capt. Sachse, tion versus cutting out the exhaust and replacing. and Allure of the Seas, Celebrity’s Solstice, Eclipse, adding “ABS was all for it.” He is also consider- “There were various theories out there, including and Silhouette,” said Lucignani, remarking Norwe- ing Polycoating the chain locker and lazaarette, and galvanic corrosion” said Sachse. “We did our own gian Cruise Lines (NCL) has applied Poly? ake to its other dif? cult to maintain areas prone to corrosion.

Image: Poly? ake www.marinelink.com 81

MR #10 (74-81).indd 81 MR #10 (74-81).indd 81 10/5/2018 11:21:10 AM10/5/2018 11:21:10 AM

80

80

82

82