Page 82: of Maritime Reporter Magazine (May 2019)

Propulsion Annual - Green Marine Tech

Read this page in Pdf, Flash or Html5 edition of May 2019 Maritime Reporter Magazine

TECH FEATURE • PROPELLERS

Prop Tech to Cut Underwater Noise

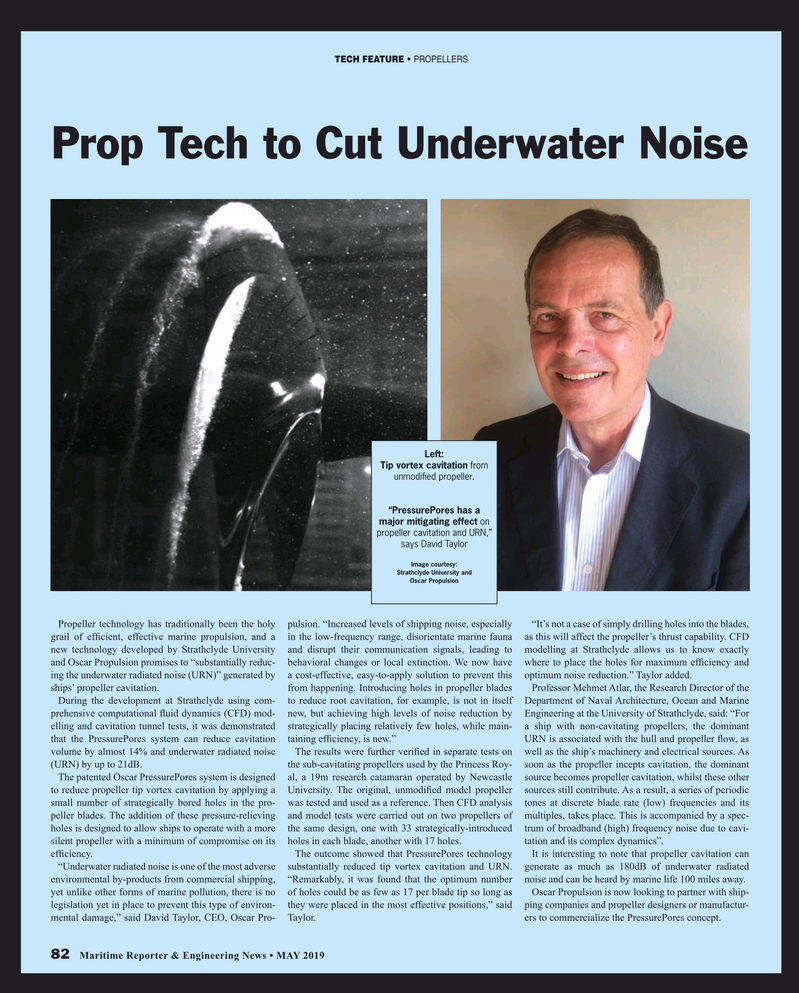

Left:

Tip vortex cavitation from unmodi? ed propeller.

“PressurePores has a major mitigating effect on propeller cavitation and URN,” says David Taylor

Image courtesy:

Strathclyde University and

Oscar Propulsion

Propeller technology has traditionally been the holy pulsion. “Increased levels of shipping noise, especially “It’s not a case of simply drilling holes into the blades, grail of ef? cient, effective marine propulsion, and a in the low-frequency range, disorientate marine fauna as this will affect the propeller’s thrust capability. CFD new technology developed by Strathclyde University and disrupt their communication signals, leading to modelling at Strathclyde allows us to know exactly and Oscar Propulsion promises to “substantially reduc- behavioral changes or local extinction. We now have where to place the holes for maximum ef? ciency and ing the underwater radiated noise (URN)” generated by a cost-effective, easy-to-apply solution to prevent this optimum noise reduction.” Taylor added.

ships’ propeller cavitation. from happening. Introducing holes in propeller blades Professor Mehmet Atlar, the Research Director of the

During the development at Strathclyde using com- to reduce root cavitation, for example, is not in itself Department of Naval Architecture, Ocean and Marine prehensive computational ? uid dynamics (CFD) mod- new, but achieving high levels of noise reduction by Engineering at the University of Strathclyde, said: “For elling and cavitation tunnel tests, it was demonstrated strategically placing relatively few holes, while main- a ship with non-cavitating propellers, the dominant that the PressurePores system can reduce cavitation taining ef? ciency, is new.” URN is associated with the hull and propeller ? ow, as volume by almost 14% and underwater radiated noise The results were further veri? ed in separate tests on well as the ship’s machinery and electrical sources. As (URN) by up to 21dB. the sub-cavitating propellers used by the Princess Roy- soon as the propeller incepts cavitation, the dominant

The patented Oscar PressurePores system is designed al, a 19m research catamaran operated by Newcastle source becomes propeller cavitation, whilst these other to reduce propeller tip vortex cavitation by applying a University. The original, unmodi? ed model propeller sources still contribute. As a result, a series of periodic small number of strategically bored holes in the pro- was tested and used as a reference. Then CFD analysis tones at discrete blade rate (low) frequencies and its peller blades. The addition of these pressure-relieving and model tests were carried out on two propellers of multiples, takes place. This is accompanied by a spec- holes is designed to allow ships to operate with a more the same design, one with 33 strategically-introduced trum of broadband (high) frequency noise due to cavi- silent propeller with a minimum of compromise on its holes in each blade, another with 17 holes. tation and its complex dynamics”.

ef? ciency. The outcome showed that PressurePores technology It is interesting to note that propeller cavitation can “Underwater radiated noise is one of the most adverse substantially reduced tip vortex cavitation and URN. generate as much as 180dB of underwater radiated environmental by-products from commercial shipping, “Remarkably, it was found that the optimum number noise and can be heard by marine life 100 miles away. yet unlike other forms of marine pollution, there is no of holes could be as few as 17 per blade tip so long as Oscar Propulsion is now looking to partner with ship- legislation yet in place to prevent this type of environ- they were placed in the most effective positions,” said ping companies and propeller designers or manufactur- mental damage,” said David Taylor, CEO, Oscar Pro- Taylor. ers to commercialize the PressurePores concept.

82 Maritime Reporter & Engineering News • MAY 2019

MR #5 (82-89).indd 82 5/3/2019 2:13:01 PM

81

81

83

83