Page 74: of Maritime Reporter Magazine (November 2019)

Workboat Edition

Read this page in Pdf, Flash or Html5 edition of November 2019 Maritime Reporter Magazine

E

EMISSION REDUCTION TECH FILES

Schottel Propulsion for

Emission-Free Push Boat

The agreement between Wärtsilä and Norsepower will pro- mote the use of Rotor Sails & support sustainable shipping.

Wärtsilä, Norsepower Sign Agreement

The technology group Wärtsilä and Norsepower, a provider of low maintenance, software operated, data veri? ed auxil- iary wind propulsion systems, have signed a service coop- eration agreement.

This will enable Norsepower to order service work from

Photo credit: TU Berlin, Department of Design and Operation of Maritime Systems

Wärtsilä, while Wärtsilä can pursue and sell Norsepower Ro- tor Sail projects with support from Norsepower. The agree- ment was signed in Q3 2019.

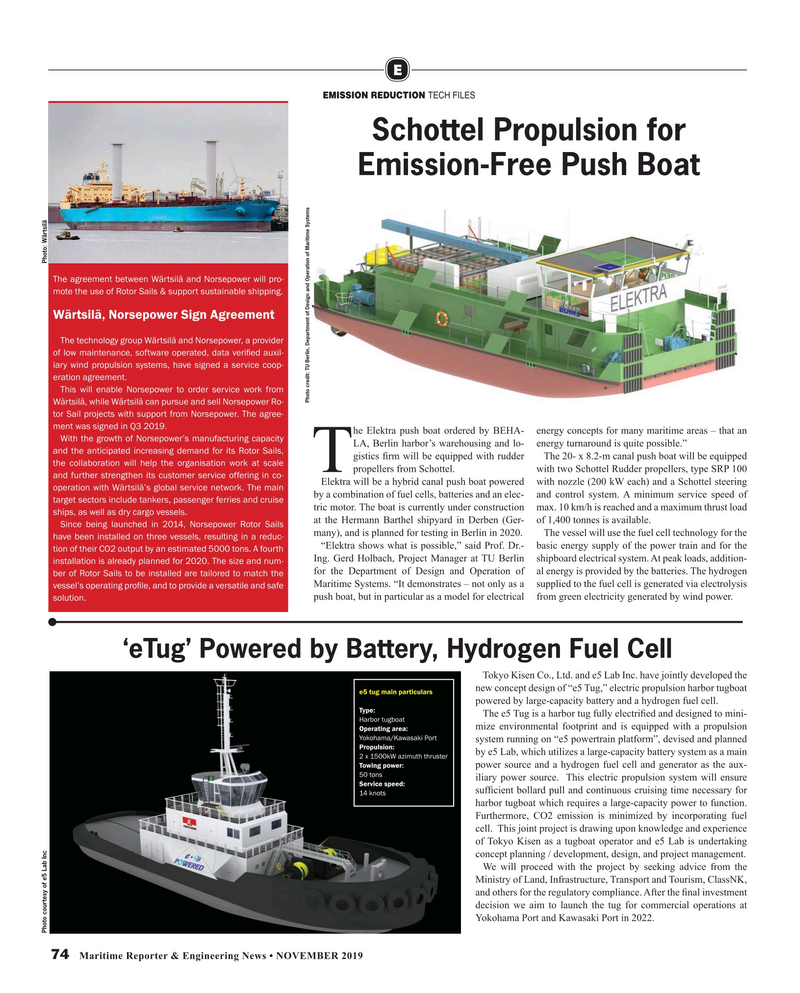

he Elektra push boat ordered by BEHA- energy concepts for many maritime areas – that an

With the growth of Norsepower’s manufacturing capacity

LA, Berlin harbor’s warehousing and lo- energy turnaround is quite possible.” and the anticipated increasing demand for its Rotor Sails, gistics ? rm will be equipped with rudder The 20- x 8.2-m canal push boat will be equipped the collaboration will help the organisation work at scale

Tpropellers from Schottel. with two Schottel Rudder propellers, type SRP 100 and further strengthen its customer service offering in co-

Elektra will be a hybrid canal push boat powered with nozzle (200 kW each) and a Schottel steering operation with Wärtsilä’s global service network. The main by a combination of fuel cells, batteries and an elec- and control system. A minimum service speed of target sectors include tankers, passenger ferries and cruise tric motor. The boat is currently under construction max. 10 km/h is reached and a maximum thrust load ships, as well as dry cargo vessels.

at the Hermann Barthel shipyard in Derben (Ger- of 1,400 tonnes is available.

Since being launched in 2014, Norsepower Rotor Sails many), and is planned for testing in Berlin in 2020. The vessel will use the fuel cell technology for the have been installed on three vessels, resulting in a reduc- “Elektra shows what is possible,” said Prof. Dr.- basic energy supply of the power train and for the tion of their CO2 output by an estimated 5000 tons. A fourth

Ing. Gerd Holbach, Project Manager at TU Berlin shipboard electrical system. At peak loads, addition- installation is already planned for 2020. The size and num- for the Department of Design and Operation of al energy is provided by the batteries. The hydrogen ber of Rotor Sails to be installed are tailored to match the

Maritime Systems. “It demonstrates – not only as a supplied to the fuel cell is generated via electrolysis vessel’s operating pro? le, and to provide a versatile and safe push boat, but in particular as a model for electrical from green electricity generated by wind power.

solution.

‘eTug’ Powered by Battery, Hydrogen Fuel Cell

Tokyo Kisen Co., Ltd. and e5 Lab Inc. have jointly developed the new concept design of “e5 Tug,” electric propulsion harbor tugboat e5 tug main particulars powered by large-capacity battery and a hydrogen fuel cell.

Type:

The e5 Tug is a harbor tug fully electri? ed and designed to mini-

Harbor tugboat mize environmental footprint and is equipped with a propulsion

Operating area:

Yokohama/Kawasaki Port system running on “e5 powertrain platform”, devised and planned

Propulsion: by e5 Lab, which utilizes a large-capacity battery system as a main 2 x 1500kW azimuth thruster power source and a hydrogen fuel cell and generator as the aux-

Towing power: 50 tons iliary power source. This electric propulsion system will ensure

Service speed: suf? cient bollard pull and continuous cruising time necessary for 14 knots harbor tugboat which requires a large-capacity power to function.

Furthermore, CO2 emission is minimized by incorporating fuel cell. This joint project is drawing upon knowledge and experience of Tokyo Kisen as a tugboat operator and e5 Lab is undertaking concept planning / development, design, and project management.

We will proceed with the project by seeking advice from the

Ministry of Land, Infrastructure, Transport and Tourism, ClassNK, and others for the regulatory compliance. After the ? nal investment decision we aim to launch the tug for commercial operations at

Yokohama Port and Kawasaki Port in 2022.

Photo courtesy of e5 Lab Inc Photo: Wärtsilä 74 Maritime Reporter & Engineering News • NOVEMBER 2019

NEW 74 77.indd 74 11/6/2019 3:27:25 PM

73

73

75

75