Page 41: of Maritime Reporter Magazine (February 2022)

Government Shipbuilding

Read this page in Pdf, Flash or Html5 edition of February 2022 Maritime Reporter Magazine

COVER STORY U.S. NAVY SHIPBUILDING

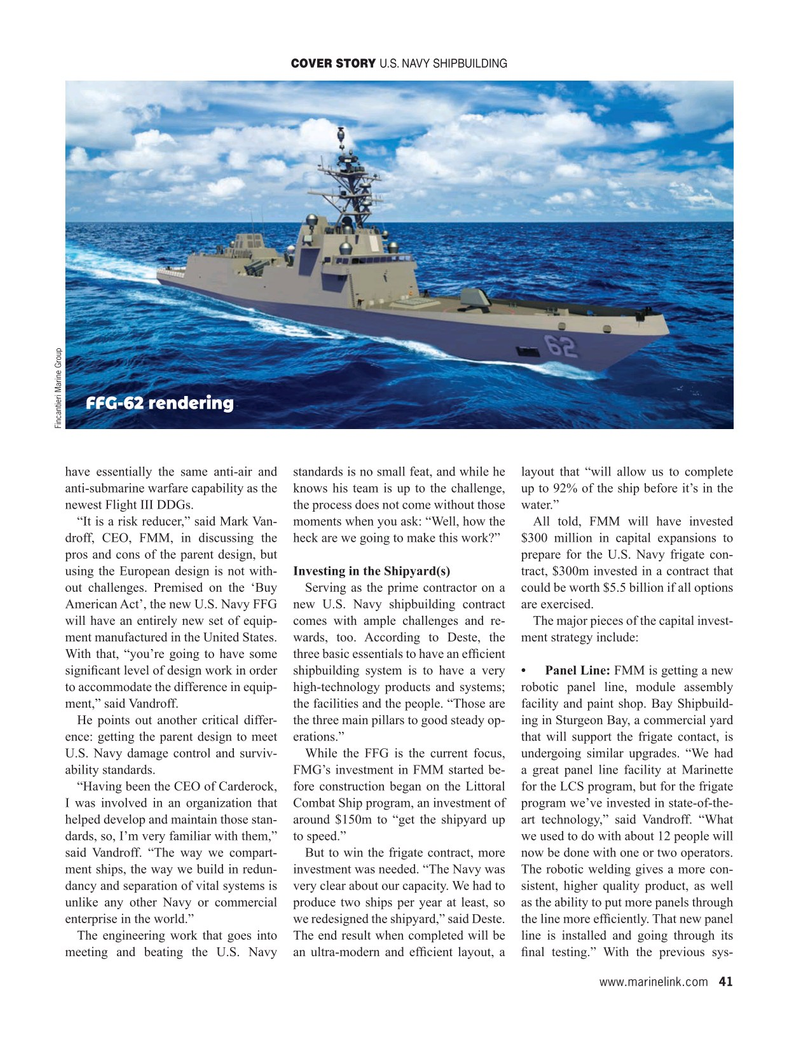

FFG-62 rendering

Fincantieri Marine Group have essentially the same anti-air and standards is no small feat, and while he layout that “will allow us to complete anti-submarine warfare capability as the knows his team is up to the challenge, up to 92% of the ship before it’s in the newest Flight III DDGs. the process does not come without those water.” “It is a risk reducer,” said Mark Van- moments when you ask: “Well, how the All told, FMM will have invested droff, CEO, FMM, in discussing the heck are we going to make this work?” $300 million in capital expansions to pros and cons of the parent design, but prepare for the U.S. Navy frigate con- using the European design is not with- Investing in the Shipyard(s) tract, $300m invested in a contract that out challenges. Premised on the ‘Buy Serving as the prime contractor on a could be worth $5.5 billion if all options

American Act’, the new U.S. Navy FFG new U.S. Navy shipbuilding contract are exercised. will have an entirely new set of equip- comes with ample challenges and re- The major pieces of the capital invest- ment manufactured in the United States. wards, too. According to Deste, the ment strategy include:

With that, “you’re going to have some three basic essentials to have an ef? cient signi? cant level of design work in order shipbuilding system is to have a very • Panel Line: FMM is getting a new to accommodate the difference in equip- high-technology products and systems; robotic panel line, module assembly ment,” said Vandroff. the facilities and the people. “Those are facility and paint shop. Bay Shipbuild-

He points out another critical differ- the three main pillars to good steady op- ing in Sturgeon Bay, a commercial yard ence: getting the parent design to meet erations.” that will support the frigate contact, is

U.S. Navy damage control and surviv- While the FFG is the current focus, undergoing similar upgrades. “We had ability standards. FMG’s investment in FMM started be- a great panel line facility at Marinette “Having been the CEO of Carderock, fore construction began on the Littoral for the LCS program, but for the frigate

I was involved in an organization that Combat Ship program, an investment of program we’ve invested in state-of-the- helped develop and maintain those stan- around $150m to “get the shipyard up art technology,” said Vandroff. “What dards, so, I’m very familiar with them,” to speed.” we used to do with about 12 people will said Vandroff. “The way we compart- But to win the frigate contract, more now be done with one or two operators. ment ships, the way we build in redun- investment was needed. “The Navy was The robotic welding gives a more con- dancy and separation of vital systems is very clear about our capacity. We had to sistent, higher quality product, as well unlike any other Navy or commercial produce two ships per year at least, so as the ability to put more panels through enterprise in the world.” we redesigned the shipyard,” said Deste. the line more ef? ciently. That new panel

The engineering work that goes into The end result when completed will be line is installed and going through its meeting and beating the U.S. Navy an ultra-modern and ef? cient layout, a ? nal testing.” With the previous sys- www.marinelink.com 41

MR #2 (34-49).indd 41 2/4/2022 1:22:49 PM

40

40

42

42