Page 45: of Maritime Reporter Magazine (August 2024)

Read this page in Pdf, Flash or Html5 edition of August 2024 Maritime Reporter Magazine

MS AMERA

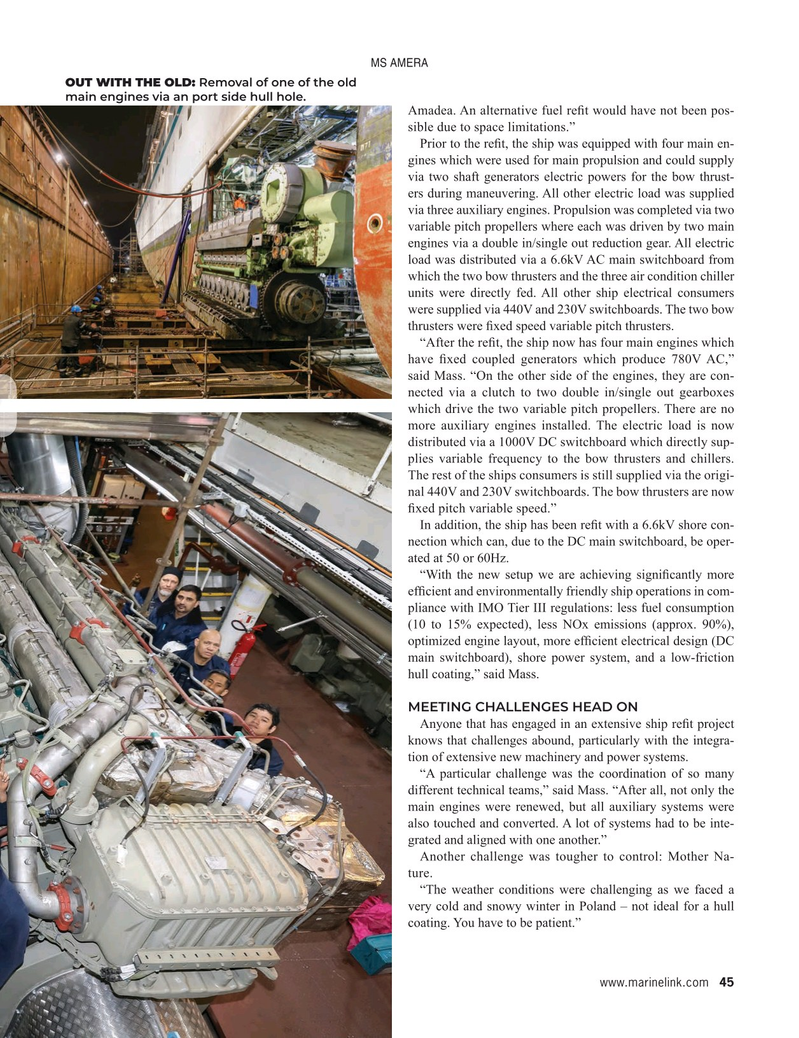

OUT WITH THE OLD: Removal of one of the old main engines via an port side hull hole.

Amadea. An alternative fuel re? t would have not been pos- sible due to space limitations.”

Prior to the re? t, the ship was equipped with four main en- gines which were used for main propulsion and could supply via two shaft generators electric powers for the bow thrust- ers during maneuvering. All other electric load was supplied via three auxiliary engines. Propulsion was completed via two variable pitch propellers where each was driven by two main engines via a double in/single out reduction gear. All electric load was distributed via a 6.6kV AC main switchboard from which the two bow thrusters and the three air condition chiller units were directly fed. All other ship electrical consumers were supplied via 440V and 230V switchboards. The two bow thrusters were ? xed speed variable pitch thrusters. “After the re? t, the ship now has four main engines which have ? xed coupled generators which produce 780V AC,” said Mass. “On the other side of the engines, they are con- nected via a clutch to two double in/single out gearboxes which drive the two variable pitch propellers. There are no

Y more auxiliary engines installed. The electric load is now distributed via a 1000V DC switchboard which directly sup- plies variable frequency to the bow thrusters and chillers.

The rest of the ships consumers is still supplied via the origi- nal 440V and 230V switchboards. The bow thrusters are now ? xed pitch variable speed.”

In addition, the ship has been re? t with a 6.6kV shore con- nection which can, due to the DC main switchboard, be oper- ated at 50 or 60Hz.

“With the new setup we are achieving signi? cantly more ef? cient and environmentally friendly ship operations in com- pliance with IMO Tier III regulations: less fuel consumption (10 to 15% expected), less NOx emissions (approx. 90%), optimized engine layout, more ef? cient electrical design (DC main switchboard), shore power system, and a low-friction hull coating,” said Mass.

MEETING CHALLENGES HEAD ON

Anyone that has engaged in an extensive ship re? t project knows that challenges abound, particularly with the integra- tion of extensive new machinery and power systems.

“A particular challenge was the coordination of so many different technical teams,” said Mass. “After all, not only the main engines were renewed, but all auxiliary systems were also touched and converted. A lot of systems had to be inte- grated and aligned with one another.”

Another challenge was tougher to control: Mother Na- ture.

“The weather conditions were challenging as we faced a very cold and snowy winter in Poland – not ideal for a hull coating. You have to be patient.” www.marinelink.com 45

MR #8 (34-49).indd 45 8/8/2024 11:23:26 AM

44

44

46

46