Page 41: of Maritime Reporter Magazine (June 2025)

Read this page in Pdf, Flash or Html5 edition of June 2025 Maritime Reporter Magazine

In the Shipyard

From Design to Delivery

Main Iron Works Completes 10th Boat for Ingram

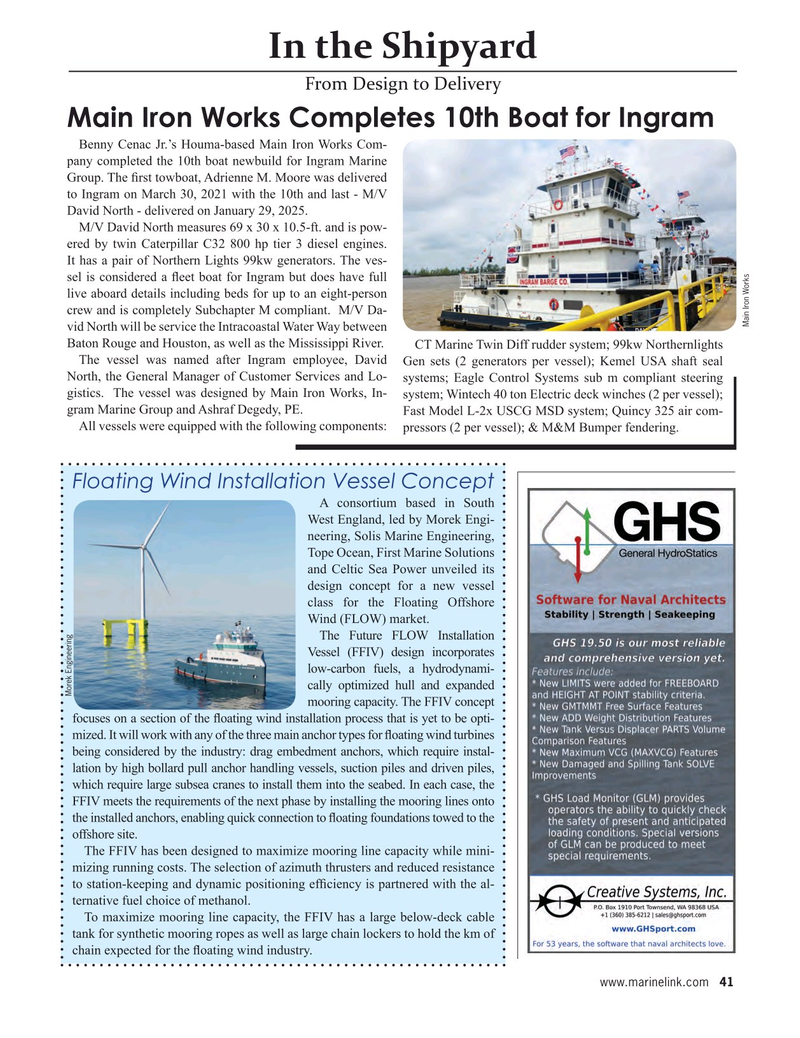

Benny Cenac Jr.’s Houma-based Main Iron Works Com- pany completed the 10th boat newbuild for Ingram Marine

Group. The ? rst towboat, Adrienne M. Moore was delivered to Ingram on March 30, 2021 with the 10th and last - M/V

David North - delivered on January 29, 2025.

M/V David North measures 69 x 30 x 10.5-ft. and is pow- ered by twin Caterpillar C32 800 hp tier 3 diesel engines.

It has a pair of Northern Lights 99kw generators. The ves- sel is considered a ? eet boat for Ingram but does have full live aboard details including beds for up to an eight-person crew and is completely Subchapter M compliant. M/V Da-

Main Iron Works vid North will be service the Intracoastal Water Way between

Baton Rouge and Houston, as well as the Mississippi River.

CT Marine Twin Diff rudder system; 99kw Northernlights

The vessel was named after Ingram employee, David Gen sets (2 generators per vessel); Kemel USA shaft seal

North, the General Manager of Customer Services and Lo- systems; Eagle Control Systems sub m compliant steering gistics. The vessel was designed by Main Iron Works, In- system; Wintech 40 ton Electric deck winches (2 per vessel); gram Marine Group and Ashraf Degedy, PE.

Fast Model L-2x USCG MSD system; Quincy 325 air com-

All vessels were equipped with the following components: pressors (2 per vessel); & M&M Bumper fendering.

Floating Wind Installation Vessel Concept

A consortium based in South

West England, led by Morek Engi- neering, Solis Marine Engineering,

Tope Ocean, First Marine Solutions and Celtic Sea Power unveiled its design concept for a new vessel class for the Floating Offshore

Wind (FLOW) market.

The Future FLOW Installation

Vessel (FFIV) design incorporates low-carbon fuels, a hydrodynami- cally optimized hull and expanded

Morek Engineering mooring capacity. The FFIV concept focuses on a section of the ? oating wind installation process that is yet to be opti- mized. It will work with any of the three main anchor types for ? oating wind turbines being considered by the industry: drag embedment anchors, which require instal- lation by high bollard pull anchor handling vessels, suction piles and driven piles, which require large subsea cranes to install them into the seabed. In each case, the

FFIV meets the requirements of the next phase by installing the mooring lines onto the installed anchors, enabling quick connection to ? oating foundations towed to the offshore site.

The FFIV has been designed to maximize mooring line capacity while mini- mizing running costs. The selection of azimuth thrusters and reduced resistance to station-keeping and dynamic positioning ef? ciency is partnered with the al- ternative fuel choice of methanol.

To maximize mooring line capacity, the FFIV has a large below-deck cable tank for synthetic mooring ropes as well as large chain lockers to hold the km of chain expected for the ? oating wind industry. www.marinelink.com 41

MR #6 (34-45).indd 41 MR #6 (34-45).indd 41 5/31/2025 7:56:10 PM5/31/2025 7:56:10 PM

40

40

42

42