Page 42: of Maritime Reporter Magazine (October 2025)

Read this page in Pdf, Flash or Html5 edition of October 2025 Maritime Reporter Magazine

In the Shipyard

From Design to Delivery foundations, a strategic step that positions the company as a full-service provider in the foundations market.

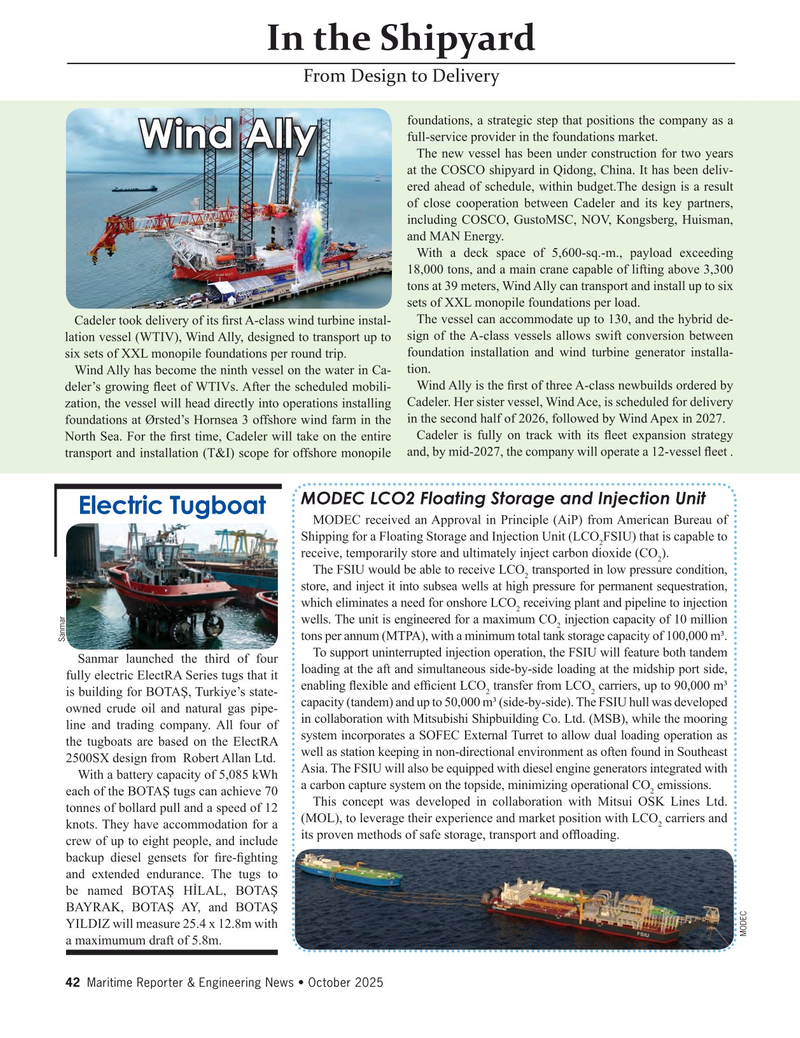

Wind AllyWind Ally

The new vessel has been under construction for two years at the COSCO shipyard in Qidong, China. It has been deliv- ered ahead of schedule, within budget.The design is a result of close cooperation between Cadeler and its key partners, including COSCO, GustoMSC, NOV, Kongsberg, Huisman, and MAN Energy.

With a deck space of 5,600-sq.-m., payload exceeding 18,000 tons, and a main crane capable of lifting above 3,300 tons at 39 meters, Wind Ally can transport and install up to six sets of XXL monopile foundations per load.

Cadeler took delivery of its ? rst A-class wind turbine instal- The vessel can accommodate up to 130, and the hybrid de- lation vessel (WTIV), Wind Ally, designed to transport up to sign of the A-class vessels allows swift conversion between six sets of XXL monopile foundations per round trip. foundation installation and wind turbine generator installa-

Wind Ally has become the ninth vessel on the water in Ca- tion.

deler’s growing ? eet of WTIVs. After the scheduled mobili- Wind Ally is the ? rst of three A-class newbuilds ordered by zation, the vessel will head directly into operations installing Cadeler. Her sister vessel, Wind Ace, is scheduled for delivery foundations at Ørsted’s Hornsea 3 offshore wind farm in the in the second half of 2026, followed by Wind Apex in 2027.

North Sea. For the ? rst time, Cadeler will take on the entire Cadeler is fully on track with its ? eet expansion strategy transport and installation (T&I) scope for offshore monopile and, by mid-2027, the company will operate a 12-vessel ? eet .

MODEC LCO2 Floating Storage and Injection Unit

Electric Tugboat

MODEC received an Approval in Principle (AiP) from American Bureau of

Shipping for a Floating Storage and Injection Unit (LCO FSIU) that is capable to 2 receive, temporarily store and ultimately inject carbon dioxide (CO ).

2

The FSIU would be able to receive LCO transported in low pressure condition, 2 store, and inject it into subsea wells at high pressure for permanent sequestration, which eliminates a need for onshore LCO receiving plant and pipeline to injection 2 wells. The unit is engineered for a maximum CO injection capacity of 10 million 2 tons per annum (MTPA), with a minimum total tank storage capacity of 100,000 m³.

Sanmar

To support uninterrupted injection operation, the FSIU will feature both tandem

Sanmar launched the third of four loading at the aft and simultaneous side-by-side loading at the midship port side, fully electric ElectRA Series tugs that it enabling ? exible and ef? cient LCO transfer from LCO carriers, up to 90,000 m³ 2 2 is building for BOTAS, Turkiye’s state- capacity (tandem) and up to 50,000 m³ (side-by-side). The FSIU hull was developed owned crude oil and natural gas pipe- in collaboration with Mitsubishi Shipbuilding Co. Ltd. (MSB), while the mooring line and trading company. All four of system incorporates a SOFEC External Turret to allow dual loading operation as the tugboats are based on the ElectRA well as station keeping in non-directional environment as often found in Southeast 2500SX design from Robert Allan Ltd.

Asia. The FSIU will also be equipped with diesel engine generators integrated with

With a battery capacity of 5,085 kWh a carbon capture system on the topside, minimizing operational CO emissions.

2 each of the BOTAS tugs can achieve 70

This concept was developed in collaboration with Mitsui OSK Lines Ltd. tonnes of bollard pull and a speed of 12 (MOL), to leverage their experience and market position with LCO carriers and 2 knots. They have accommodation for a its proven methods of safe storage, transport and of? oading.

crew of up to eight people, and include backup diesel gensets for ? re-? ghting and extended endurance. The tugs to be named BOTAS H ILAL, BOTAS

BAYRAK, BOTAS AY, and BOTAS

YILDIZ will measure 25.4 x 12.8m with

MODEC a maximumum draft of 5.8m. 42 Maritime Reporter & Engineering News • October 2025

MR #10 (34-45).indd 42 MR #10 (34-45).indd 42 10/1/2025 2:57:39 PM10/1/2025 2:57:39 PM

41

41

43

43