Page 26: of Offshore Engineer Magazine (Mar/Apr 2014)

Read this page in Pdf, Flash or Html5 edition of Mar/Apr 2014 Offshore Engineer Magazine

Drilling

Virtual reality

Current drilling simulators strive to ofer operators hazard-free, cost-efective training solutions in a true-to-life environment.

Greg App provides an overview of the latest technology. ome of the most substantial tech- nological innovations in drilling

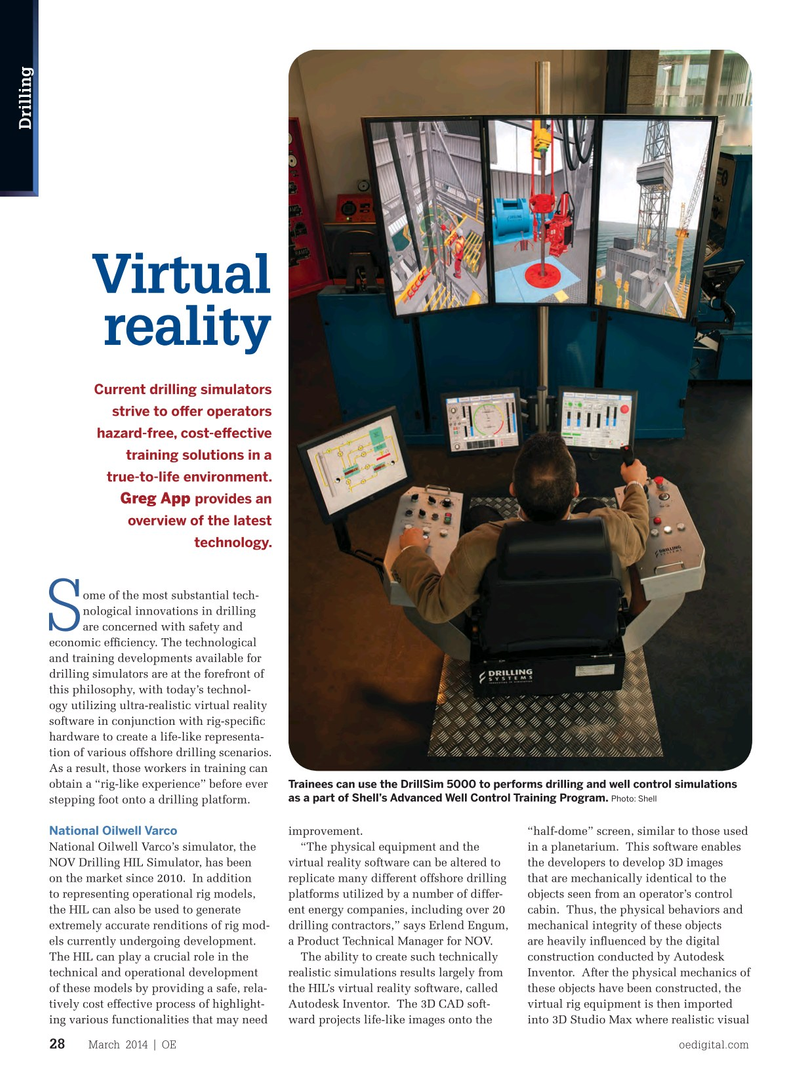

S are concerned with safety and economic effciency. The technological and training developments available for drilling simulators are at the forefront of this philosophy, with today’s technol- ogy utilizing ultra-realistic virtual reality software in conjunction with rig-specifc hardware to create a life-like representa- tion of various offshore drilling scenarios.

As a result, those workers in training can obtain a “rig-like experience” before ever

Trainees can use the DrillSim 5000 to performs drilling and well control simulations as a part of Shell’s Advanced Well Control Training Program. Photo: Shell stepping foot onto a drilling platform. improvement. “half-dome” screen, similar to those used

National Oilwell Varco

National Oilwell Varco’s simulator, the “The physical equipment and the in a planetarium. This software enables

NOV Drilling HIL Simulator, has been virtual reality software can be altered to the developers to develop 3D images on the market since 2010. In addition replicate many different offshore drilling that are mechanically identical to the to representing operational rig models, platforms utilized by a number of differ- objects seen from an operator’s control the HIL can also be used to generate ent energy companies, including over 20 cabin. Thus, the physical behaviors and extremely accurate renditions of rig mod- drilling contractors,” says Erlend Engum, mechanical integrity of these objects els currently undergoing development. a Product Technical Manager for NOV. are heavily infuenced by the digital

The HIL can play a crucial role in the The ability to create such technically construction conducted by Autodesk technical and operational development realistic simulations results largely from Inventor. After the physical mechanics of of these models by providing a safe, rela- the HIL’s virtual reality software, called these objects have been constructed, the tively cost effective process of highlight- Autodesk Inventor. The 3D CAD soft- virtual rig equipment is then imported ing various functionalities that may need ward projects life-like images onto the into 3D Studio Max where realistic visual

March 2014 | OE oedigital.com 28 000_OE0314_D&C1-Greg.indd 28 2/21/14 12:02 PM

25

25

27

27