Page 36: of Offshore Engineer Magazine (Mar/Apr 2014)

Read this page in Pdf, Flash or Html5 edition of Mar/Apr 2014 Offshore Engineer Magazine

EPIC

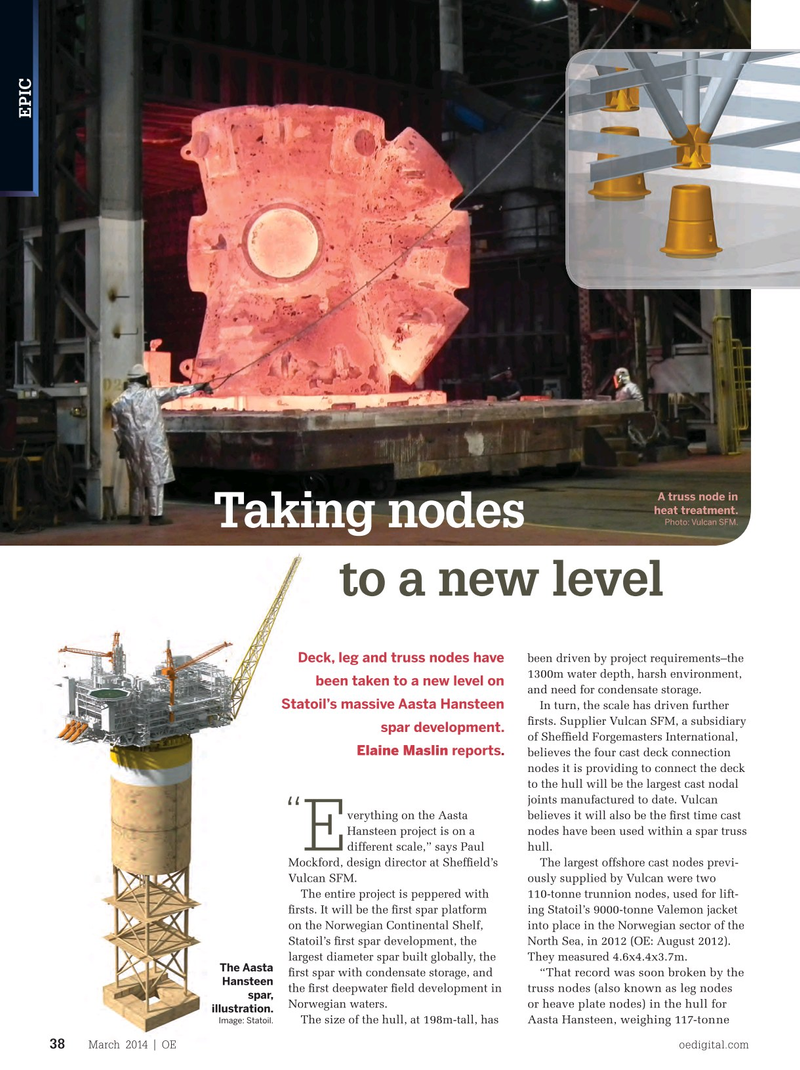

A truss node in heat treatment.

Photo: Vulcan SFM.

Taking nodes to a new level been driven by project requirements–the

Deck, leg and truss nodes have 1300m water depth, harsh environment, been taken to a new level on and need for condensate storage.

Statoil’s massive Aasta Hansteen

In turn, the scale has driven further ? rsts. Supplier Vulcan SFM, a subsidiary spar development. of Shef? eld Forgemasters International,

Elaine Maslin reports.

believes the four cast deck connection nodes it is providing to connect the deck to the hull will be the largest cast nodal joints manufactured to date. Vulcan verything on the Aasta believes it will also be the ? rst time cast “

Hansteen project is on a nodes have been used within a spar truss

E different scale,” says Paul hull.

Mockford, design director at Shef? eld’s The largest offshore cast nodes previ-

Vulcan SFM. ously supplied by Vulcan were two

The entire project is peppered with 110-tonne trunnion nodes, used for lift- ? rsts. It will be the ? rst spar platform ing Statoil’s 9000-tonne Valemon jacket on the Norwegian Continental Shelf, into place in the Norwegian sector of the

Statoil’s ? rst spar development, the North Sea, in 2012 (OE: August 2012). largest diameter spar built globally, the They measured 4.6x4.4x3.7m.

The Aasta “That record was soon broken by the ? rst spar with condensate storage, and

Hansteen truss nodes (also known as leg nodes the ? rst deepwater ? eld development in spar, or heave plate nodes) in the hull for

Norwegian waters. illustration.

Image: Statoil.

Aasta Hansteen, weighing 117-tonne

The size of the hull, at 198m-tall, has

March 2014 | OE oedigital.com 38 000_0314_Epic2_Vulcan.indd 38 2/21/14 1:54 PM

35

35

37

37